Nail beautifying polish and preparation method thereof

A technology of nail polish and parts by weight, used in manicures, pedicures, pharmaceutical formulations, etc., can solve problems such as irritating odor, human injury, soft nails, etc., to achieve strong adhesion, good ventilation, and moderate viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

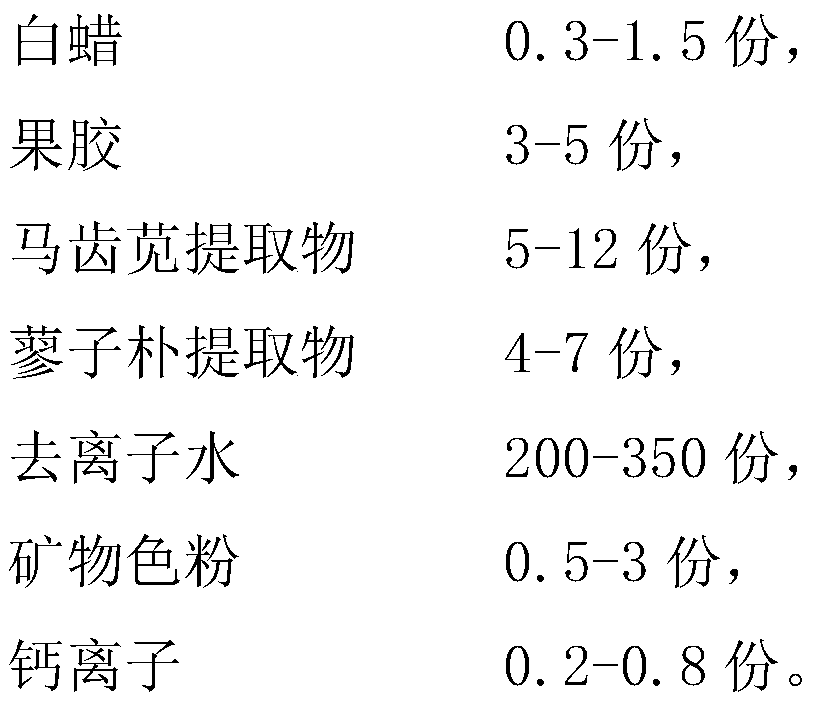

[0035] 1. Raw material ratio (parts by weight)

[0036]

[0037]

[0038] 2. Preparation method

[0039] (1) Weigh the raw materials according to the above ratio;

[0040] (2) Combining white wax, pectin, calcium ions, deionized water, purslane extract and Polygonum oleracea extract and evenly stirring to obtain mixture A;

[0041] (3) Add mineral toner to mixture A and stir at 50°C for 10 minutes to obtain mixture B;

[0042] (4) Mix the essence, cocoa butter and myristyl myristate evenly, and stir at 80°C for 15 minutes to obtain mixture C;

[0043] (5) Mix the mixture B and the mixture C evenly, and treat with ultrasonic for 15 minutes, and the ultrasonic power is 300W.

[0044] The preparation method of described purslane extract is as follows:

[0045] (1) drying the purslane after removing roots and impurities at 60°C to constant weight, and passing through a 40-mesh sieve after crushing to obtain purslane powder;

Embodiment 2

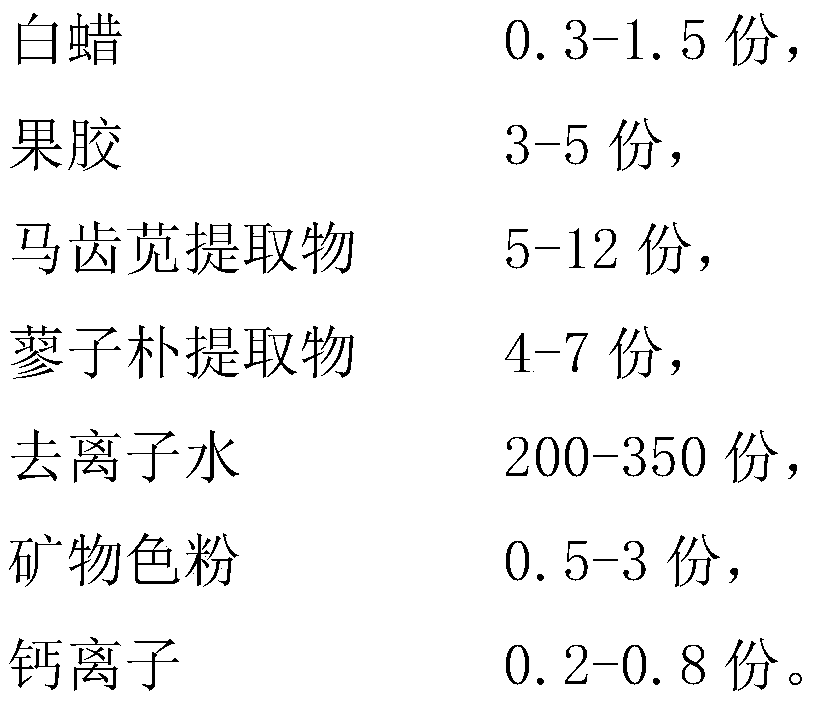

[0055] 1. Raw material ratio (parts by weight)

[0056]

[0057] 2. Preparation method

[0058] (1) Weigh the raw materials according to the above ratio;

[0059] (2) Combining white wax, pectin, calcium ions, deionized water, purslane extract and Polygonum oleracea extract and evenly stirring to obtain mixture A;

[0060] (3) Add mineral toner to mixture A and stir at 50°C for 10 minutes to obtain mixture B;

[0061] (4) Mix the essence, cocoa butter and myristyl myristate evenly, and stir at 80°C for 15 minutes to obtain mixture C;

[0062] (5) Mix the mixture B and the mixture C evenly, and treat with ultrasonic for 15 minutes, and the ultrasonic power is 300W.

[0063] The preparation method of described purslane extract is as follows:

[0064] (1) drying the purslane after removing roots and impurities at 60°C to constant weight, and passing through a 40-mesh sieve after crushing to obtain purslane powder;

[0065] (2) Add purslane powder into ethanol solution wit...

Embodiment 3

[0074] 1. Raw material ratio (parts by weight)

[0075]

[0076]

[0077] 2. Preparation method

[0078] (1) Weigh the raw materials according to the above ratio;

[0079] (2) Combining white wax, pectin, calcium ions, deionized water, purslane extract and Polygonum oleracea extract and evenly stirring to obtain mixture A;

[0080] (3) Add mineral toner to mixture A and stir at 50°C for 10 minutes to obtain mixture B;

[0081] (4) Mix the essence, cocoa butter and myristyl myristate evenly, and stir at 80°C for 15 minutes to obtain mixture C;

[0082] (5) Mix the mixture B and the mixture C evenly, and treat with ultrasonic for 15 minutes, and the ultrasonic power is 300W.

[0083] The preparation method of described purslane extract is as follows:

[0084] (1) drying the purslane after removing roots and impurities at 60°C to constant weight, and passing through a 40-mesh sieve after crushing to obtain purslane powder;

[0085] (2) Add purslane powder into ethanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com