Ionic liquid phase-change heat-storage catalytic oxidation equipment

A technology of phase change heat storage and catalytic oxidation, which is applied in gas treatment, separation methods, and separation of dispersed particles, etc. It can solve the problems of large temperature changes, poor safety, and low heat storage density, achieve constant temperature, and improve mixing uniformity , the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

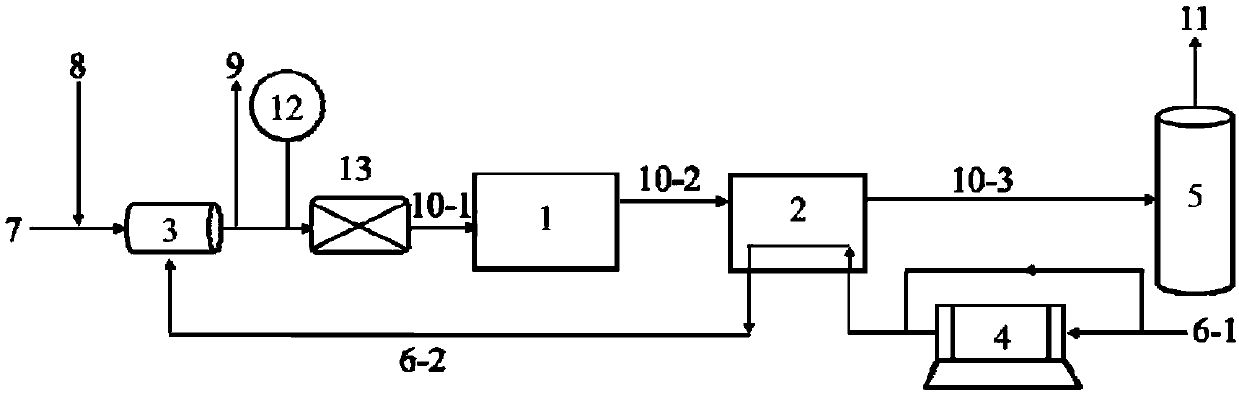

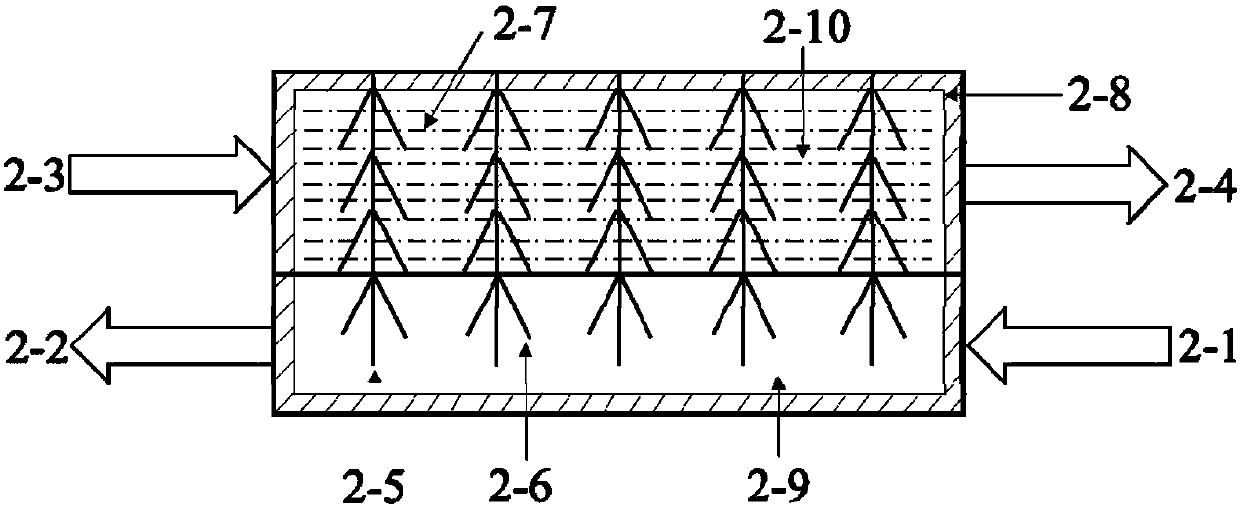

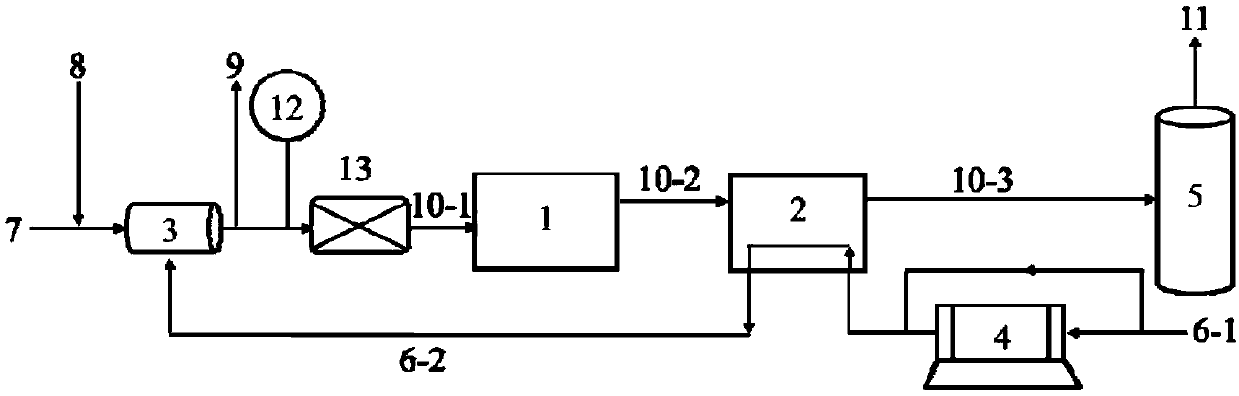

[0025] An ionic liquid phase change regenerative catalytic oxidation device, comprising a gas mixer, a flame arrester, a catalytic oxidation reactor, a phase change heat accumulator, and a tail gas treatment device, the gas mixer is provided with a gas inlet pipeline, and the gas mixing The device is connected to the fire arresting device through the pipeline, the fire arresting device is connected to the catalytic oxidation reactor through the pipeline, the catalytic oxidation reactor is connected to the phase change heat accumulator through the pipeline, and the phase change heat accumulator is connected to the tail gas treatment device through the pipeline; The phase change heat accumulator is equipped with a cold fluid inlet, a cold fluid outlet, a hot fluid inlet, and a hot fluid outlet. The phase change heat accumulator is equipped with a heat pipe, a heat conduction fin, an ionic liquid phase change heat storage material, and a heat storage chamber. , There is an insulat...

Embodiment 2

[0028] According to the conditions described in Example 1, the organic gas containing ethylene, methane and carbon dioxide produced by a certain chemical plant is pressurized to 1.0 MPa by the compressor 4 and then enters the jet mixer 3 to mix with oxygen, and the oxygen content is controlled to be lower than 8%. The mixed gas enters the phase change heat accumulator 2 for preheating to 350°C. The heat accumulator uses immobilized imidazole ionic liquid (1-hexadecyl-3-methylimidazolium bromide ionic liquid), and the phase change The temperature is around 350°C, the outermost layer of the accumulator is filled with thermal insulation cotton, the preheated mixed gas enters the catalytic oxidation reactor 1 through the fire arresting device 13, and the fire arresting device is filled with explosion-proof corrugated fire arresting filler. The mixed gas is converted into carbon dioxide and water in the catalytic oxidation reactor, and the operating temperature is 350-380°C accordin...

Embodiment 3

[0030]According to the conditions described in Example 1, the organic gas containing ethylene, methane and carbon dioxide produced by a certain chemical plant is pressurized to 1.0 MPa by the compressor 4 and then enters the jet mixer 3 to mix with oxygen, and the oxygen content is controlled to be lower than 8%. The mixed gas enters the phase change heat accumulator 2 to be preheated to 350°C. The heat accumulator adopts immobilized imidazole ionic liquid (1-octyl-3-methylimidazolium hexafluorophosphate ionic liquid), and the phase change temperature At about 350°C, the outermost layer of the accumulator is filled with thermal insulation cotton, and the preheated mixed gas enters the catalytic oxidation reactor 1 through the fire arresting device 13, and the flame arresting device is filled with explosion-proof corrugated fire arresting filler. The mixed gas is converted into carbon dioxide and water in the catalytic oxidation reactor, and the operating temperature is 350-380°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com