A method for preparing nanoscale barium molybdate particles

A technology of nano-barium molybdate and barium molybdate, which is applied in nanotechnology, nano-optics, nanotechnology, etc., can solve the problems that the particle size of nano-barium molybdate cannot be controlled, and achieves the advantages of simple preparation method and low preparation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

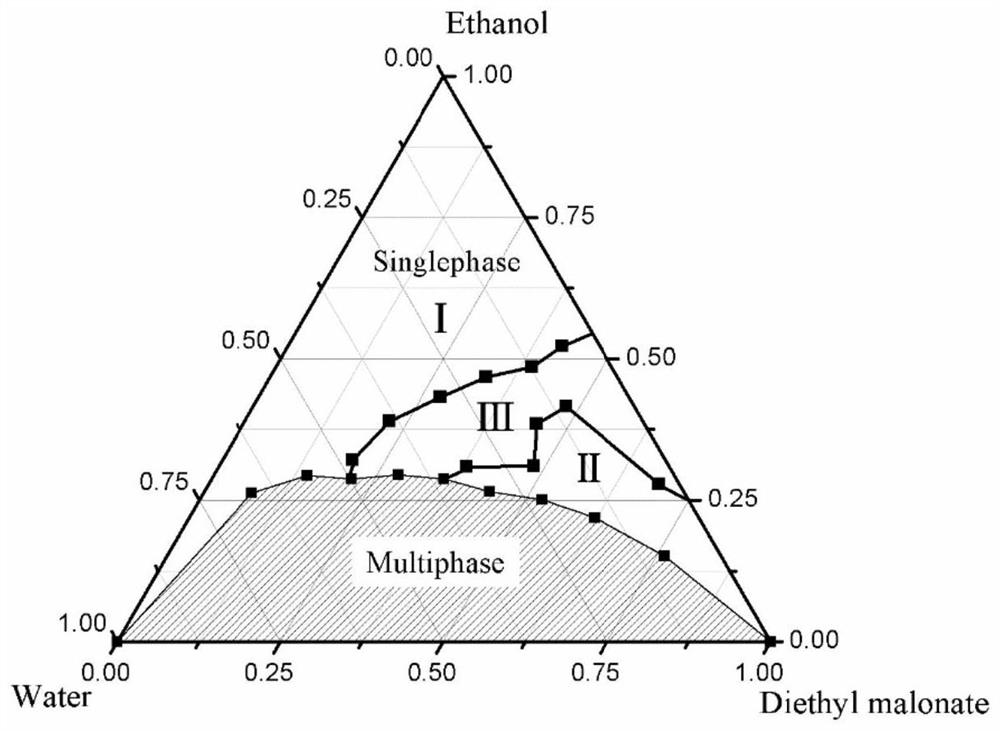

[0045] Construction of diethyl malonate / ethanol / water surfactant-free microemulsion system:

[0046] In a dry and clean test tube, weigh the mass ratios of diethyl malonate and water to be 9:1, 8:2, 7:3, 6:4, 5:5, 4:6, 3:7 , 2:8, and 1:9 binary mixtures totaling 1.0g, then place the test tube in a constant temperature water bath to maintain a constant temperature, and the temperature of the water bath is maintained at 25±0.2°C. Under magnetic stirring, drop ethanol into the mixed solution in the test tube, at this time, the mixed solution gradually changed from turbid to clear. Record the mass of ethanol added during clarification. This operation was repeated three times, and the average value of ethanol mass was taken for graphing. The mass of ethanol added in each test tube is: 0.1811g, 0.283g, 0.3396g, 0.3679g, 0.4104g, 0.4245g, 0.4104g, 0.4273g and 0.3651g. Draw a ternary phase diagram, such as figure 1 shown.

[0047] The division of microemulsion systems with differ...

Embodiment 2

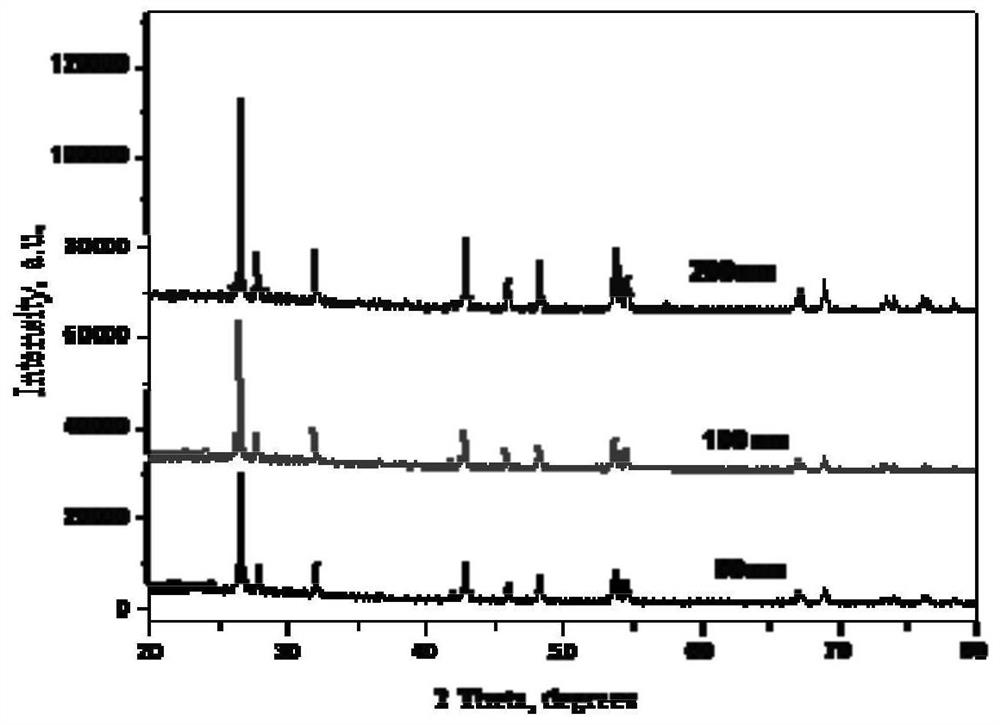

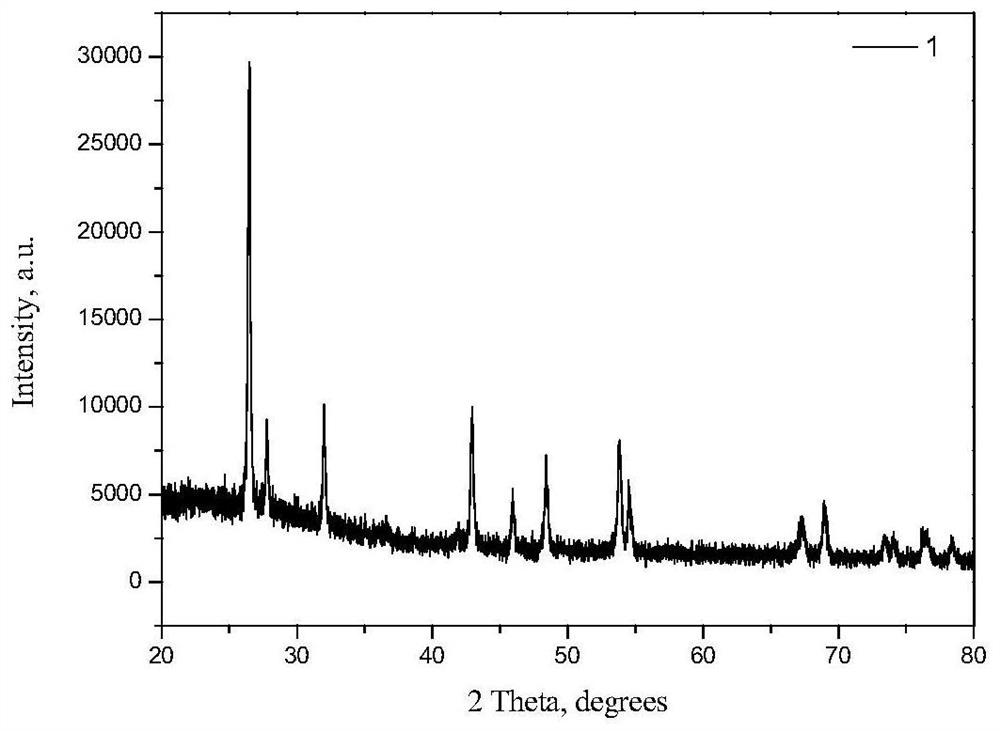

[0050] 50nm BaMoO 4 Preparation method of nanoparticles:

[0051] (1) Prepare 0.025mol / L Na 2 MoO 4 Aqueous solution, weigh 7.0g ethanol and 9.2g diethyl malonate with an analytical balance and mix them, and gradually add 3g Na 2 MoO 4 aqueous solution. Stir at room temperature for 30min to obtain 4 2- W / O microemulsion.

[0052] (2) Prepare 0.025mol / L BaCl 2 Aqueous solution, weigh 7.0g of ethanol and 9.2g of diethyl malonate with an analytical balance and mix, and gradually add 3.0g of BaCl under stirring condition 2 aqueous solution. Stir at room temperature for 30min to obtain 2+ W / O microemulsion.

[0053] (3) the Ba containing obtained in step (2) 2+ The W / O microemulsion was added dropwise to the MoO-containing microemulsion obtained in step (1) under magnetic stirring. 4 2- In the W / O microemulsion, keep the reaction temperature at about 25°C, and magnetically stir for 100 hours to form a milky white mixture. Then all the mixture was centrifuged, washed ...

Embodiment 3

[0055] 100nm BaMoO 4 Preparation method of nanoparticles:

[0056] (1) Prepare 0.025mol / L Na 2 MoO 4 Aqueous solution, weigh 7.0g ethanol and 9.2g diethyl malonate with an analytical balance and mix, and gradually add 3.0g Na 2 MoO 4 aqueous solution. Stir at room temperature for 30min to obtain 4 2- W / O microemulsion.

[0057] (2) Prepare 0.025mol / L BaCl 2 Aqueous solution, weigh 7.0g ethanol and 9.2g diethyl malonate with an analytical balance and mix, gradually add 3g BaCl under stirring condition 2 aqueous solution. Stir at room temperature for 30min to obtain 2+ W / O microemulsion.

[0058] (3) the Ba containing obtained in step (2) 2+ The W / O microemulsion was added dropwise to the MoO-containing microemulsion obtained in step (1) under magnetic stirring. 4 2- In the W / O microemulsion, the reaction temperature was fixed at about 25°C, and magnetic stirring was maintained for 5 minutes to form a milky white mixture; then the mixture was transferred to a polyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com