Preparation method of scale inhibitor

A technology of scale inhibitors and additives, applied in the field of scale inhibitor preparation, can solve the problems of scale and corrosion inhibitors that are difficult to degrade, environmental pollution, etc., and achieve increased scale inhibition effect, improved tolerance, good biological activity and degradability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

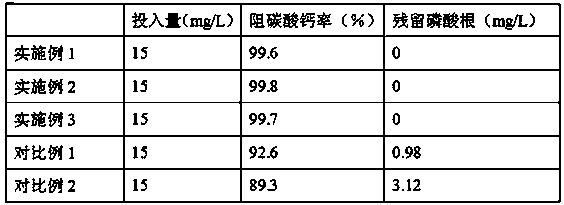

Examples

preparation example Construction

[0034] The preparation method of described trace additive is:

[0035] A. Take the mixed plant and solvent to grind at a mass ratio of 3-5:15, collect the grinding mixture, heat the grinding mixture at 90-105°C for 6 hours, cool to room temperature, and put the heated mixture into a steam explosion device , carry out steam explosion, set the pressure at 3.5-4.0MPa, maintain the pressure for 70-80s, and collect steam explosion objects;

[0036] B. Mix the steam explosion product and the mixed enzyme evenly according to the mass ratio of 12~14:1~3, carry out enzymolysis for 8 hours, filter, collect the filtrate, decolorize the filtrate through activated carbon, collect the decolorized liquid, concentrate the decolorized liquid, and concentrate to The volume of the decolorizing solution is 65-70%, the concentrated solution is collected, and the concentrated solution is mixed with ethylene glycol diglycidyl ether at a mass ratio of 1:3 to obtain the additive.

[0037] A kind of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com