Degradable plastic bag beneficial to water purification

A water purification and plastic bag technology, applied in the field of plastics, can solve the problems of affecting growth, blockage of hydropower stations, time-consuming and laborious cleaning, etc., and achieve the effects of improving tensile resistance, increasing pore spacing, and promoting degradation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A degradable plastic bag beneficial to water body purification, the plastic bag material includes the following components in parts by weight:

[0045] 30 parts of carboxy-modified polyvinyl alcohol;

[0046] 20 parts of polyethersulfone;

[0047]20 parts of modified starch;

[0048] 15 parts of polyimide;

[0049] 8 parts of polyacrylamide;

[0050] 10 parts of polyaluminum chloride;

[0051] 7 parts of nano-crosslinked silicon-based porous polymer.

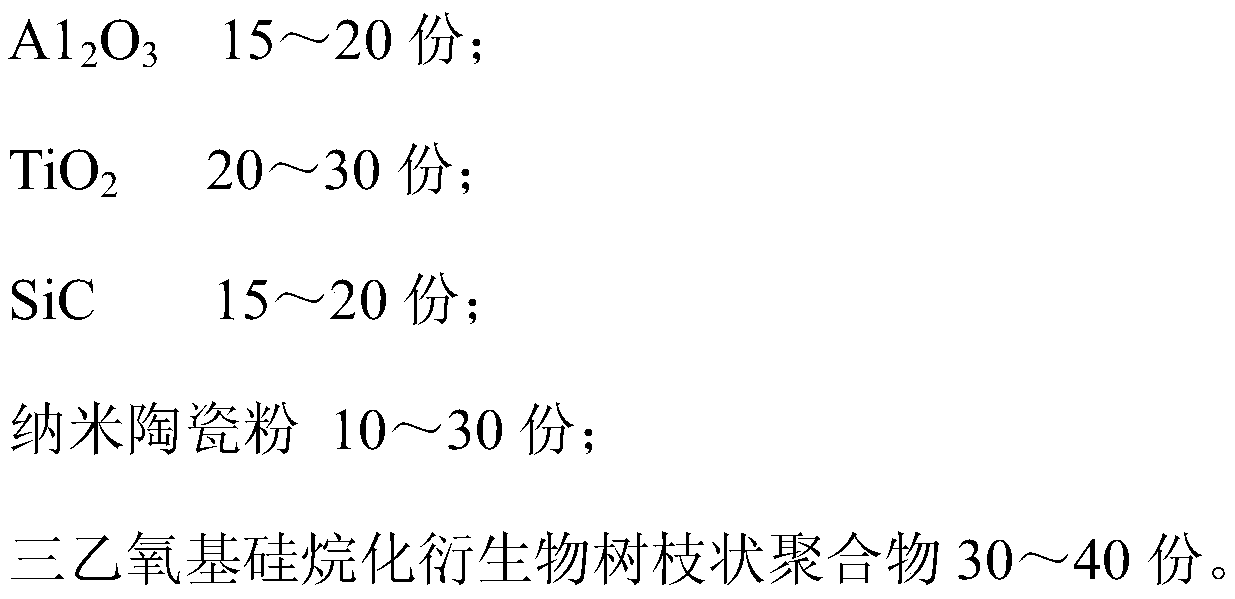

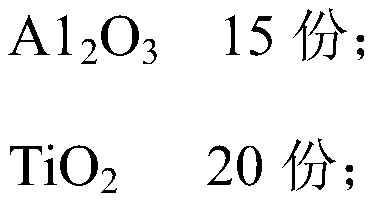

[0052] Wherein, the nano-crosslinked silicon-based porous polymer includes the following components in parts by weight:

[0053]

[0054]

[0055] Wherein, triethoxy silylated derivative dendrimers include the following components in parts by weight:

[0056] A total of 30 parts of polypropylene diimine and polyethylene imine, including 10 parts of polypropylene diimine and 20 parts of polyethylene imine;

[0057] 40 parts of 3-triethoxysilylpropyl isocyanate;

[0058] 20 parts of 4-dimethylaminopyridine;

...

Embodiment 2

[0072] A degradable plastic bag beneficial to water body purification, the plastic bag material includes the following components in parts by weight:

[0073] 40 parts of carboxy-modified polyvinyl alcohol;

[0074] 30 parts of polyethersulfone;

[0075] 25 parts of modified starch;

[0076] 25 parts of polyimide;

[0077] 12 parts of polyacrylamide;

[0078] 15 parts of polyaluminum chloride;

[0079] 10 parts of nano-crosslinked silicon-based porous polymer.

[0080] Wherein, the nano-crosslinked silicon-based porous polymer includes the following components in parts by weight:

[0081]

[0082] Wherein, triethoxy silylated derivative dendrimers include the following components in parts by weight:

[0083] 40 parts of polyglycerol ester;

[0084] 50 parts of 3-triethoxysilylpropyl isocyanate;

[0085] 30 parts of 4-dimethylaminopyridine;

[0086] Poly-β-cyclodextrin 25 parts.

[0087] The preparation method of triethoxy silylated derivative dendrimers comprises ...

Embodiment 3

[0099] A degradable plastic bag beneficial to water body purification, the plastic bag material includes the following components in parts by weight:

[0100] 35.5 parts of carboxy-modified polyvinyl alcohol;

[0101] 24.5 parts of polyethersulfone;

[0102] 22 parts of modified starch;

[0103] 20 parts of polyimide;

[0104] 10 parts of polyacrylamide;

[0105] 12.6 parts of polyaluminum chloride;

[0106] 8.5 parts of nano-crosslinked silicon-based porous polymer.

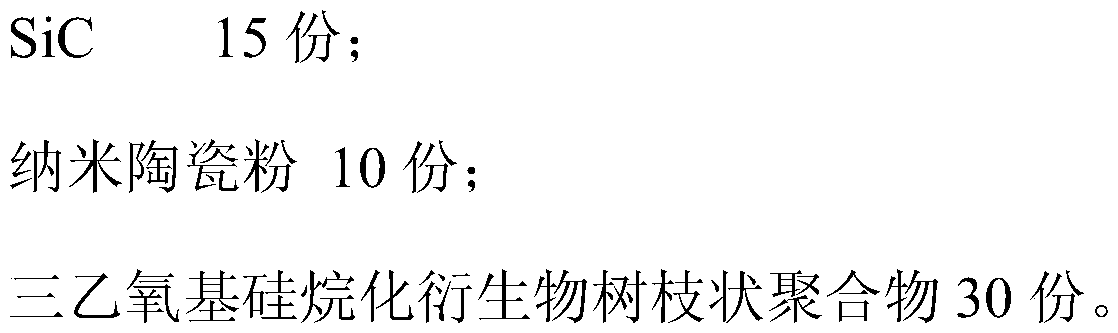

[0107] Wherein, the nano-crosslinked silicon-based porous polymer includes the following components in parts by weight:

[0108]

[0109] Wherein, triethoxy silylated derivative dendrimers include the following components in parts by weight:

[0110] 34 parts of polypropylene diimine;

[0111] 44.5 parts of 3-triethoxysilylpropyl isocyanate;

[0112] 26 parts of 4-dimethylaminopyridine;

[0113] 20 parts of poly-β-cyclodextrin.

[0114] Wherein, the preparation method of triethoxysilylated derivativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com