A kind of epoxy resin thermally conductive insulating material and preparation method thereof

A heat-conducting insulating material, epoxy resin technology, applied in the direction of plastic/resin/wax insulators, heat exchange materials, organic insulators, etc., can solve problems such as complex preparation process, achieve simple preparation method, excellent insulation performance, and easy The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

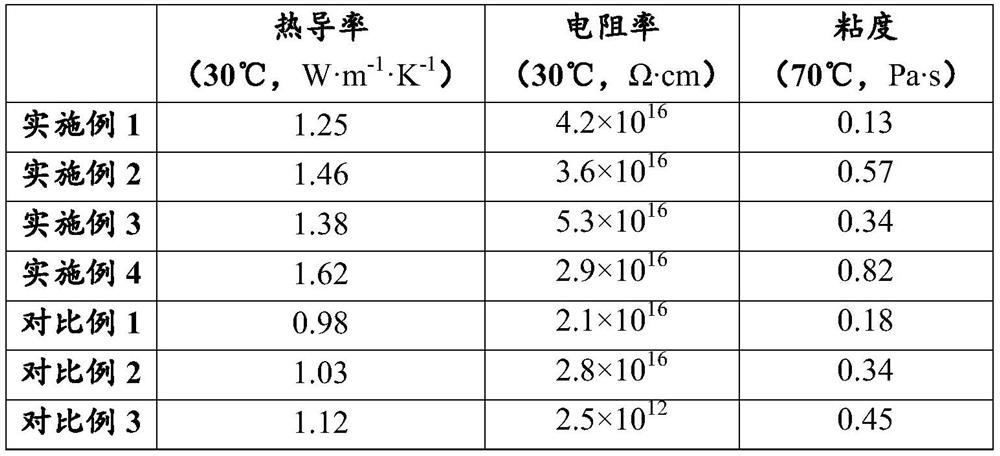

Examples

Embodiment 1

[0035] This embodiment provides an epoxy resin thermally conductive insulating material, the preparation method of which comprises:

[0036] Mix three kinds of fillers with different particle sizes with a total volume fraction of 35% with bisphenol A epoxy matrix and phthalic anhydride curing agent and heat to 50°C under pressure of 1.3×10 4 Vacuum stirring in Pa environment for 20min, then pouring into the mold, heating and curing at 70°C and 120°C successively, the curing time is 2h and 18h respectively. The three fillers are all boron nitride, the average particle size ratio of the three fillers is 4:1.6:0.8 according to the particle size, the particle number ratio is 1:0.9:2.2 according to the particle size, and the largest average particle size The particle size of the filler was 22 μm.

Embodiment 2

[0038]This embodiment provides an epoxy resin thermally conductive insulating material, the preparation method of which comprises:

[0039] Mix three kinds of fillers with different particle sizes with a total volume fraction of 40% with E51 epoxy matrix and hexahydrophthalic anhydride curing agent, heat to 70°C and press at a pressure of 1.8×10 4 Vacuum stirring under Pa environment for 3 hours, then pouring into the mold, heating and curing at 80°C and 130°C successively, the curing time is 1h and 23h respectively. The three fillers are all mixtures of boron nitride, silicon nitride, and silicon oxide at a volume ratio of 1:1:2, and the average particle diameter ratio of the three fillers is arranged as 4:1.656:1.2 according to particle size, and the particle number ratio The particle size arrangement is 0.98:1:2.03, and the particle size of the filler with the largest average particle size is 18 μm.

Embodiment 3

[0041] This embodiment provides an epoxy resin thermally conductive insulating material, and its preparation method includes:

[0042] Mix three kinds of fillers with different particle sizes with a total volume fraction of 37%, mix with bisphenol F epoxy matrix and methyl hexahydrophthalic anhydride curing agent, heat to 120°C and press at a pressure of 1.7×10 4 Vacuum stirring in Pa environment for 10min, then pouring into the mold, heating and curing at 120°C and 180°C successively, the curing time is 2h and 3h respectively. The three fillers are all mixtures of boron nitride, aluminum nitride, and silicon nitride in a mass ratio of 3:5:1, and the average particle diameter ratio of the three fillers is arranged as 4:1.656:0.9 according to particle size, and the particle number ratio The particle size arrangement is 1.05:1:1.96, and the particle size of the filler with the largest average particle size is 11 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com