A waveguide pressure sensor and detection method based on m-z structure

A pressure sensor, M-Z technology, used in fluid pressure measurement using optical methods, measurement of force by measuring the change of optical properties of materials when they are stressed, instruments, etc., can solve problems such as limited range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

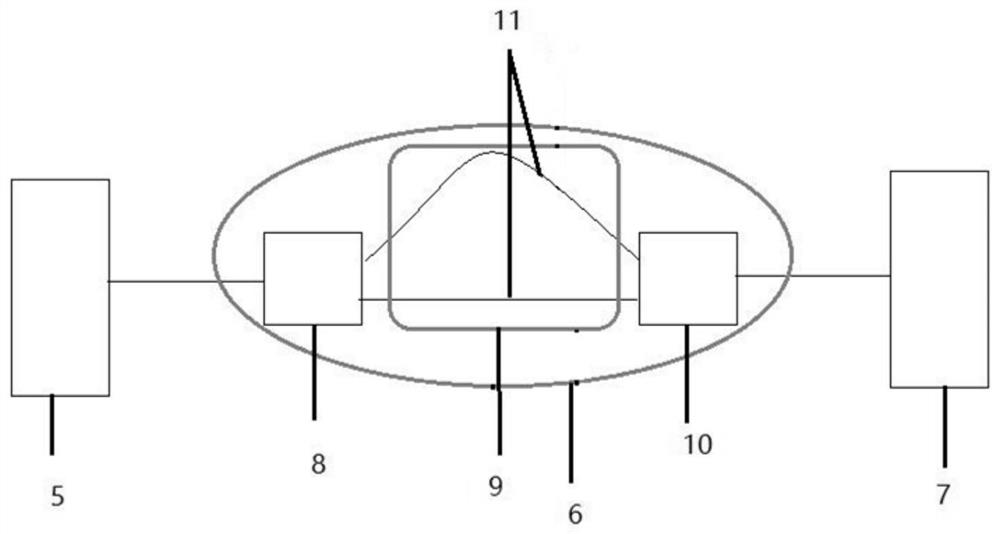

[0044] A waveguide pressure sensor based on M-Z structure, such as figure 1 As shown, it includes a single-wavelength light source 5, an M-Z structure 6 and an optical power meter 7; the single-wavelength light source 5, the M-Z structure 6 and the optical power meter 7 are connected in sequence, and the M-Z structure 6 includes an input coupler 8 connected in sequence, consisting of two different lengths The pressure sensing region 9 and the output coupler 10 are composed of a single-mode waveguide 11 . Such as Figure 6 As shown, one of the two single-mode waveguides 11 is linear and the other is sinusoidal, and the length difference ΔL between the two single-mode waveguides 11 is 0-10 mm. Since the sinusoidal shape is easy to design in the optical simulation software and export the pattern, it can be used as the preferred type.

[0045] The single-mode waveguide 11 is a strip waveguide or a ridge waveguide, the width of the single-mode waveguide 11 is 0.5-8 μm, and the thic...

Embodiment 2

[0049] According to the waveguide pressure sensor based on the M-Z structure provided in Embodiment 1, the difference is that:

[0050] Such as Figure 7 As shown, among the two single-mode waveguides 11, one is linear, and the other is arc spliced, and the length difference between the two single-mode waveguides 11 is 0-50 mm. When ΔL is 50mm, the sensor range is 2MPa.

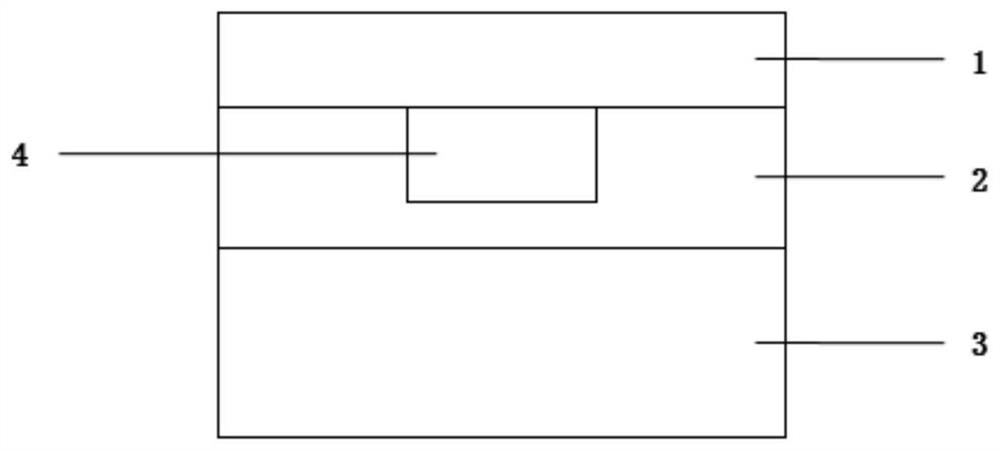

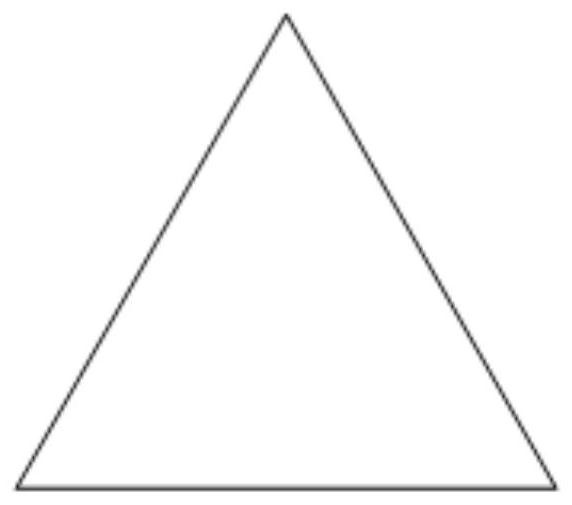

[0051] The upper part of the two single-mode waveguides 11 with different lengths in the pressure sensing area 9 is provided with a force equalization module, such as image 3 and Figure 4 As shown, the shape of the uniform force module is a regular pyramid. The bottom surface of the force equalizing module is arranged on the pressure sensing area 9 , and the bottom surface of the force equalizing module coincides with the surface of the pressure sensing area 9 .

Embodiment 3

[0053] According to the waveguide pressure sensor based on the M-Z structure provided in Embodiment 1, the difference is that:

[0054] Such as Figure 8 As shown, among the two single-mode waveguides 11, one is linear, and the other is formed by splicing the two ends of the linear waveguide 12 with the arc waveguide 13 respectively, and the length difference between the two single-mode waveguides 11 is 0 -50mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com