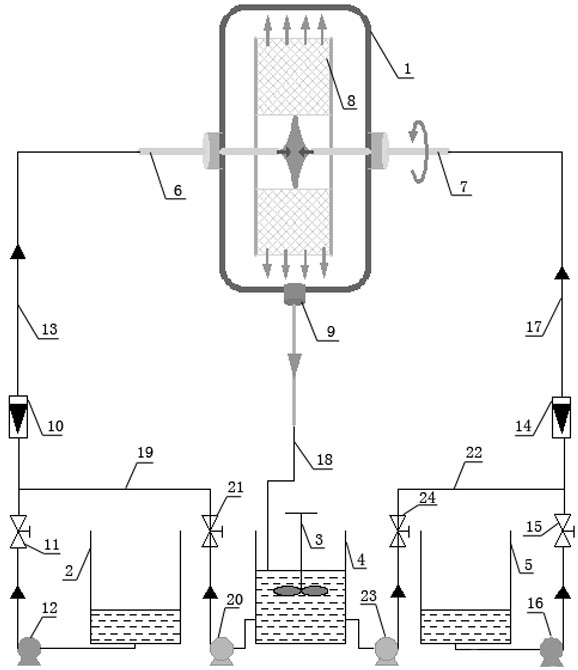

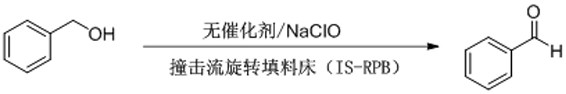

Device and method for preparing benzaldehyde in impinging flow rotating packed bed

A technology of rotating packed bed and impingement flow, applied in feeding device, preparation of carbon-based compounds, chemical instruments and methods, etc., can solve the problems of low product quality of benzaldehyde, less by-products, harsh reaction conditions, etc. Effects of enhanced mixing and mass transfer processes, faster reaction rates, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

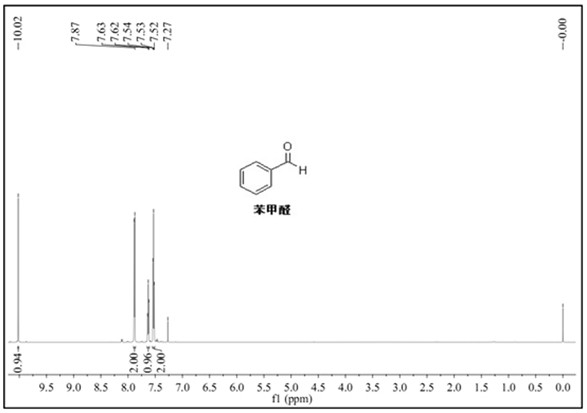

[0023] Add 5.41 g (0.05 mol) benzyl alcohol and dissolve it in 500 mL ethyl acetate to the liquid storage tank I in sequence, dilute the sodium hypochlorite solution (0.05 mol) to 500 mL and place it in the liquid storage tank III, set the rotational speed of the rotating packed bed to 300 rpm, Flow rate is 100L / h, open valve Ⅰ and valve Ⅳ, close valve Ⅱ and valve Ⅲ, turn on pump Ⅰ and pump Ⅳ, turn off pump Ⅱ and pump Ⅲ, when the reaction liquid in storage tank Ⅰ and storage tank Ⅲ passes through the impact flow When the rotating packed bed completely flows into the liquid storage tank II, immediately close the pump I and pump IV and the valve I and valve IV, open the valve II and valve III as well as the pump II and pump III at the same time, and start the mechanical agitation of the liquid storage tank II, The two streams of reaction materials passed through the impinging flow rotating packing bed again, and the reaction liquid was passed into the liquid storage tank II, and ...

Embodiment 2

[0026] Add 5.41 g (0.05 mol) benzyl alcohol and dissolve it in 500 mL ethyl acetate to the liquid storage tank I in sequence, dilute the sodium hypochlorite solution (0.15 mol) to 500 mL and place it in the liquid storage tank III, set the rotating packing bed speed to 500 rpm, Flow rate is 100L / h, open valve Ⅰ and valve Ⅳ, close valve Ⅱ and valve Ⅲ, turn on pump Ⅰ and pump Ⅳ, turn off pump Ⅱ and pump Ⅲ, when the reaction liquid in storage tank Ⅰ and storage tank Ⅲ passes through the impact flow When the rotating packed bed completely flows into the liquid storage tank II, immediately close the pump I and pump IV and the valve I and valve IV, open the valve II and valve III as well as the pump II and pump III at the same time, and start the mechanical agitation of the liquid storage tank II, The two streams of reaction materials passed through the impinging flow rotating packing bed again, and the reaction liquid was passed into the liquid storage tank II, and the reaction liqu...

Embodiment 3

[0029]Add 5.41 g (0.05 mol) of benzyl alcohol and dissolve it in 500 mL of ethyl acetate to the liquid storage tank I in sequence, dilute the sodium hypochlorite solution (0.25 mol) to 500 mL and place it in the liquid storage tank III, set the rotating packing bed speed to 800 rpm, Flow rate is 100L / h, open valve Ⅰ and valve Ⅳ, close valve Ⅱ and valve Ⅲ, turn on pump Ⅰ and pump Ⅳ, turn off pump Ⅱ and pump Ⅲ, when the reaction liquid in storage tank Ⅰ and storage tank Ⅲ passes through the impact flow When the rotating packed bed completely flows into the liquid storage tank II, immediately close the pump I and pump IV and the valve I and valve IV, open the valve II and valve III as well as the pump II and pump III at the same time, and start the mechanical agitation of the liquid storage tank II, The two streams of reaction materials passed through the impinging flow rotating packed bed again, and the reaction liquid was passed into the liquid storage tank II, and the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com