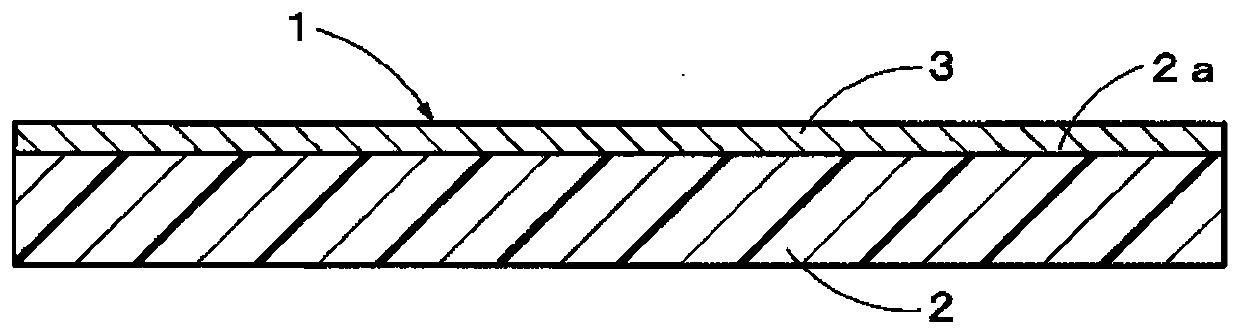

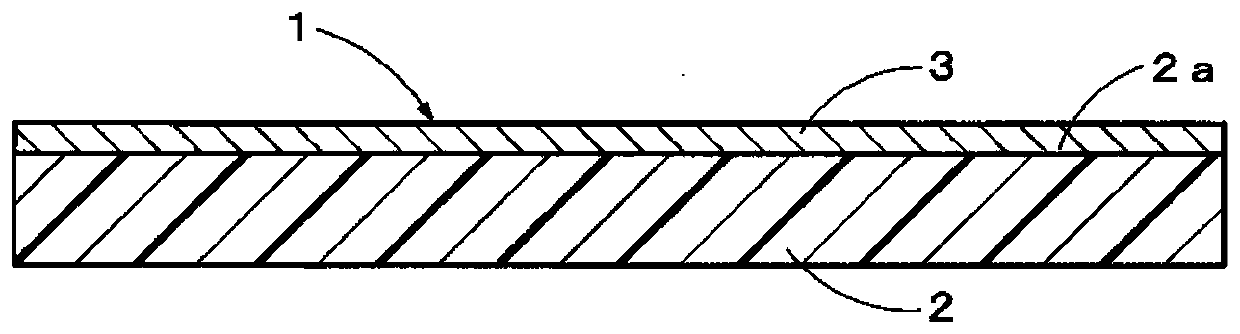

Transparent conductive film and manufacturing method thereof

A technology of transparent conductivity and manufacturing method, which is applied in the direction of cable/conductor manufacturing, chemical instruments and methods, conductive layers on insulating carriers, etc., can solve problems such as rise in resistivity, damage to ITO layer characteristics, etc., and achieve excellent crack resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] (polymer film substrate)

[0077] As the polymer film substrate, a polyethylene terephthalate (PET) film of O300E (thickness 125 μm) manufactured by Mitsubishi Plastics Corporation was used.

[0078] (Formation of organic dielectric layer)

[0079] A thermosetting resin composition containing a melamine resin: an alkyd resin: an organosilane condensate in a weight ratio of 2:2:1 in terms of solid content was diluted with methyl ethyl ketone so that the solid content concentration became 8% by weight. The obtained diluted composition was applied to one main surface of the film while conveying the PET film roll-to-roll, and heat-cured at 150° C. for 2 minutes to form an organic dielectric layer with a film thickness of 35 nm.

[0080] (degassing treatment)

[0081] The obtained PET film with an organic dielectric layer was installed in a vacuum sputtering device, and was wound up while the film was advanced in close contact with a heated film-forming roll. While moving...

Embodiment 2

[0087] A transparent conductive film was obtained in the same manner as in Example 1, except that a single-layer transparent conductive layer having a thickness of 25 nm was formed using a target having a tin oxide concentration of 10% by weight of ITO.

Embodiment 3

[0089] A transparent conductive film was obtained in the same manner as in Example 2 except that the organic dielectric layer was not formed on the polymer film substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com