Single-lithium-ion conductive polymer lithium salt, lithium secondary battery electrolyte and lithium secondary battery

A technology of conductive polymer and lithium secondary battery, applied in the field of single lithium ion conductive polymer lithium salt, lithium secondary battery electrolyte, can solve the problem of safe lithium salt anion concentration polarization, etc., and achieve excellent lithium ion migration performance, excellent cycle performance, good flame retardancy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

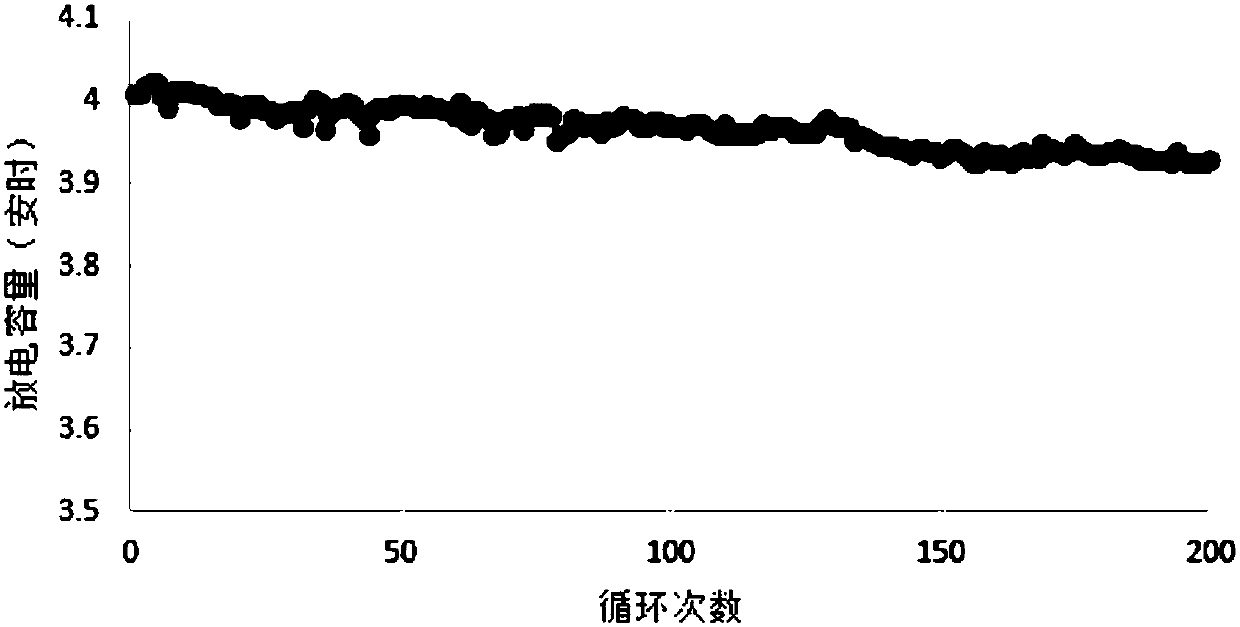

Embodiment 1

[0068] A lithium secondary battery electrolyte, comprising molecular structure formula such as conductive lithium salt shown in formula (A), by weight ratio of ethylene carbonate (EC), dimethyl carbonate (DMC) and ethyl methyl carbonate (EMC) The non-aqueous organic solvent formed by mixing at 30:30:40, and electrolyte additives, the electrolyte additives include the following components in mass percentage: 2% VC, 3% FEC, 3% PS, 2% FB , 3% DN, wherein the concentration of the conductive lithium salt is 1.0mol / L,

[0069]

[0070] Preparation of Lithium Secondary Battery Electrolyte

[0071]In a glove box filled with argon, weigh 1.0 mol of poly(ethylene-p-benzenesulfonyl)(pentafluorocyclotriphosphazene)imide lithium and dissolve it in 2% VC, 3% FEC, 3% PS, 2% FB, 3% DN in a mixed solvent of EC:DMC:EMC weight ratio = 30:30:40, fully stirred evenly, and the lithium secondary battery electrolyte of Example 1 of the present invention was obtained.

[0072] Preparation of lith...

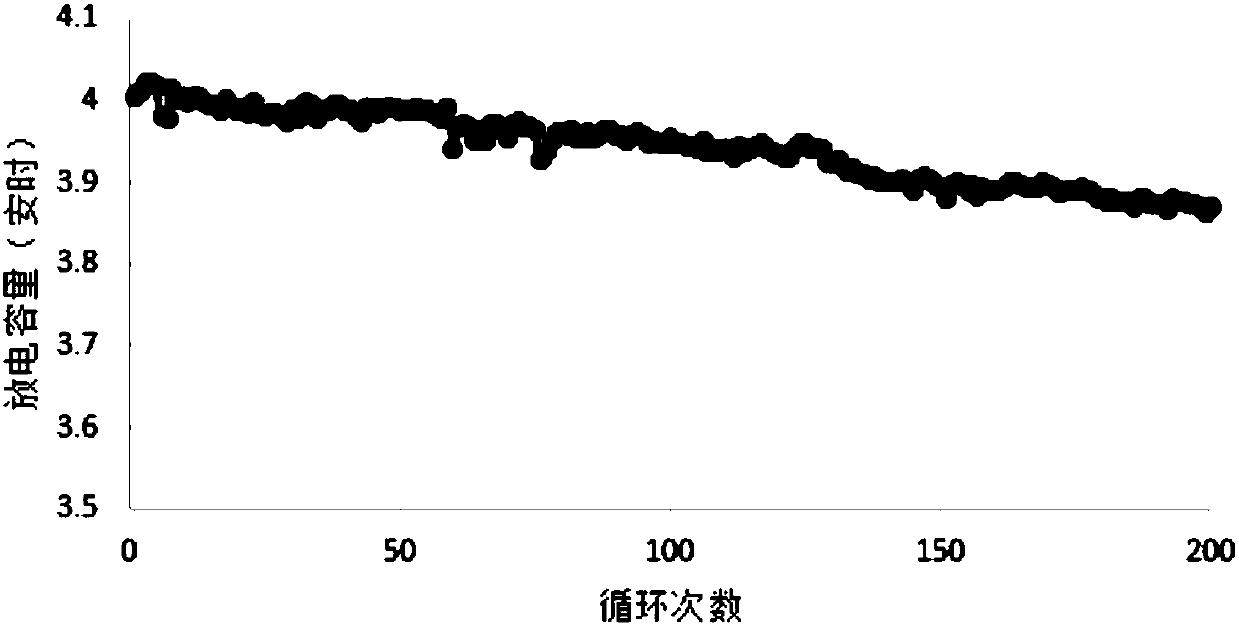

Embodiment 2

[0077] An electrolyte solution for a lithium secondary battery. The difference between this embodiment and Example 1 is that the conductive lithium salt is a conductive lithium salt (poly(ethylene methylene sulfonyl)(pentamethene) Lithium fluorocyclotriphosphazene) imide,

[0078]

[0079] The preparation method of the lithium secondary battery electrolyte and the lithium secondary battery in this embodiment is the same as that of Example 1.

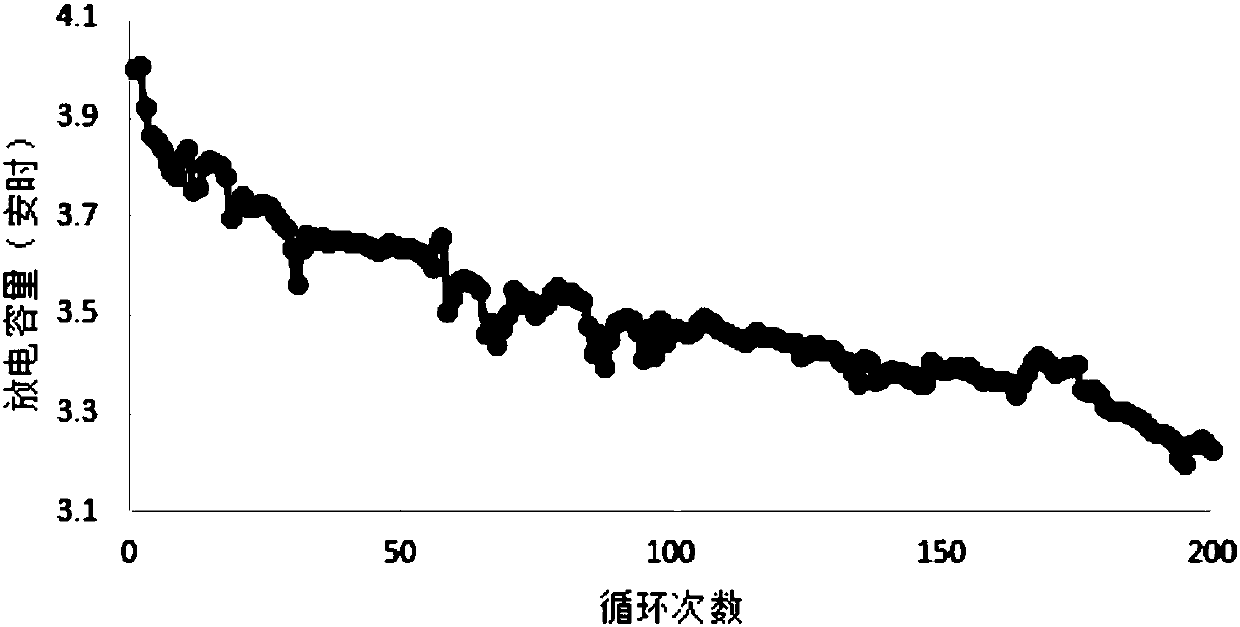

Embodiment 3

[0081] An electrolyte solution for a lithium secondary battery. The difference between this embodiment and Embodiment 1 is that the conductive lithium salt is a conductive lithium salt poly(ethylene-p-benzenesulfonyl)(tetrafluoro- Lithium 3-phenoxycyclotriphosphazene)imide,

[0082]

[0083] The preparation method of the lithium secondary battery electrolyte and the lithium secondary battery in this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com