Method and system for purifying exhaust gas containing hydrogen chloride gas and organic chlorine compound gas

A hydrogen chloride gas and waste gas purification technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as poor economy, hidden safety hazards, perforation leakage, etc., achieve good economic benefits, improve service life, and avoid dew point corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

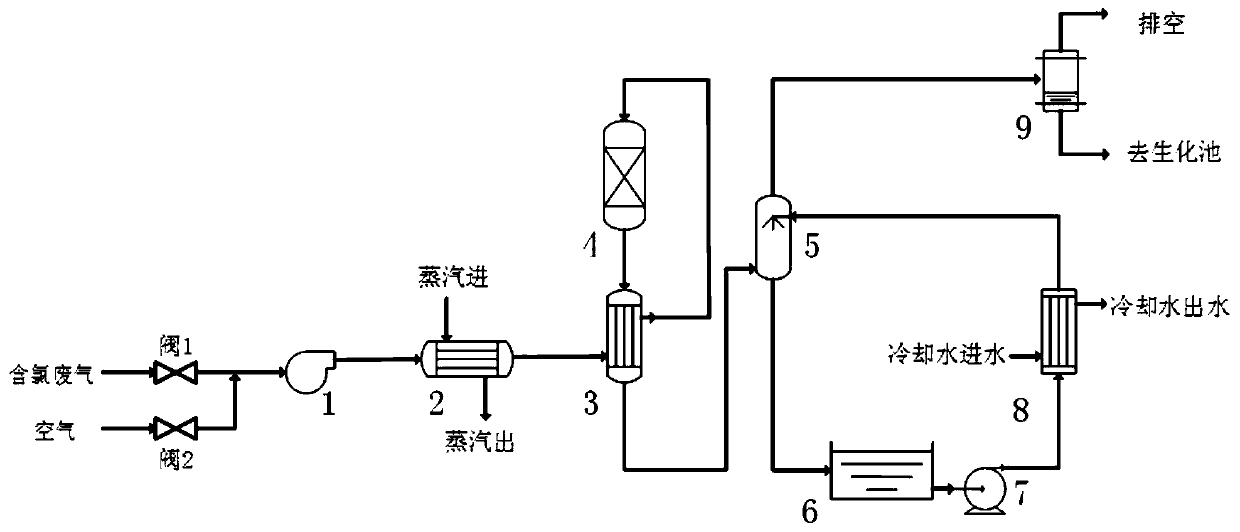

[0041] This embodiment adopts figure 1 In the process shown, the reaction adopts a fixed-bed reactor. In the waste gas containing hydrogen chloride gas and organic chlorine compound gas in this embodiment, the organic chlorine compound is chlorobenzene, and the concentration of chlorobenzene is 5024.9mg / Nm 3 , HCl content is 150 mg / Nm 3 .

[0042] The catalyst used in the fixed-bed reactor of this example is a supported transition metal oxide catalyst, and the catalyst carrier is TiO 2 , the active component of the catalyst is Cr 2 o 3 and V 2 o 5 , V 2 o 5 The loading is 7%, Cr 2 o 3 The loading capacity of the catalyst is 3%, the impregnation method is adopted during the preparation of the catalyst, and the particle size of the catalyst is 2-4mm.

[0043] (1) After the above-mentioned chlorine-containing waste gas is mixed with air, the mixed gas is blown by a fan at 1300m 3 / h access figure 1 The chlorine-containing exhaust gas purification device, wherein the a...

Embodiment 2

[0049] This embodiment adopts figure 1 In the process shown, the reaction adopts a fixed-bed reactor. In the waste gas containing hydrogen chloride gas and organic chlorine compound gas in this embodiment, the organic chlorine compound is dichloromethane, and the concentration of dichloromethane is 13270.3mg / Nm 3 , HCl content is 200mg / Nm 3 .

[0050] The catalyst used in the fixed-bed reactor of this embodiment is a supported transition metal oxide catalyst, and the catalyst carrier is Al 2 o 3 , the active component of the catalyst is Cr 2 o 3 , Cr 2 o 3 The loading capacity of the catalyst is 8%, the impregnation method is adopted during the preparation of the catalyst, and the particle size of the catalyst is 2-4mm.

[0051] (1) After the above-mentioned chlorine-containing waste gas is mixed with air, the mixed gas is blown by a fan at 1100m 3 / h access figure 1 The chlorine-containing waste gas purification device, wherein the air flow is 100m 3 / h.

[0052] ...

Embodiment 3

[0057] This embodiment adopts figure 1 In the process shown, the reaction adopts a fixed-bed reactor. In the waste gas containing hydrogen chloride gas and organic chlorine compound gas in this embodiment, the organic chlorine compound is 1,2 dichloroethane, and the concentration of 1,2 dichloroethane 11487.6 mg / Nm 3 , HCl content is 500mg / Nm 3 .

[0058] The catalyst used in the fixed-bed reactor of this embodiment is a supported transition metal oxide catalyst, and the catalyst carrier is Al 2 o 3 , the active component of the catalyst is Cr 2 o 3 and CeO 2 , Cr 2 o 3 The loading is 8%, CeO 2 The loading capacity of the catalyst is 12%, the impregnation method is adopted during the preparation of the catalyst, and the particle size of the catalyst is 2-4mm.

[0059] (1) After the above-mentioned chlorine-containing waste gas is mixed with air, the mixed gas is blown by a fan at 1200m 3 / h access figure 1 The chlorine-containing waste gas purification device, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com