Preparation method and application of titanium carbide modified bismuth-based photocatalyst for converting nitrogen to ammonia under visible light

A photocatalyst and visible light technology, applied in the preparation/separation of ammonia, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of restricting practical applications, unfavorable photocatalytic performance, etc., and achieve electron-hole recombination rate The effect of reducing and improving photocatalytic performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

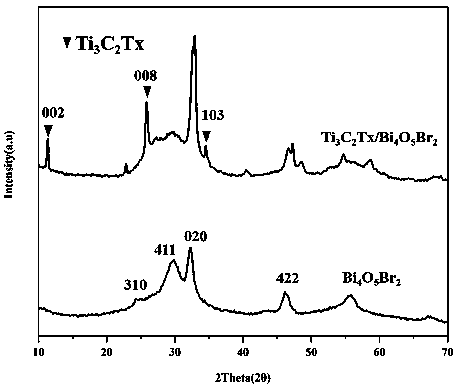

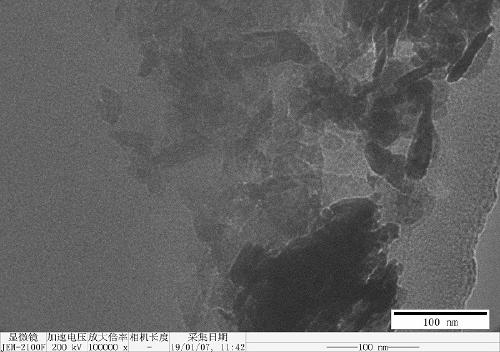

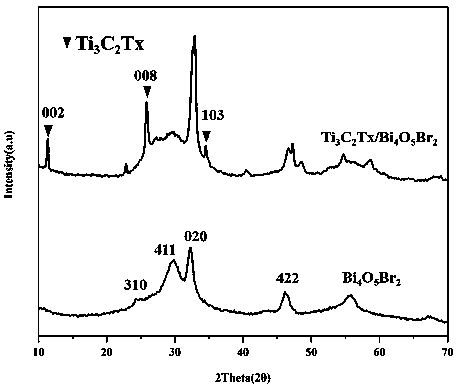

[0038] Weigh 0.9702g of bismuth nitrate pentahydrate and 50mg of Ti with an analytical balance 3 C 2 T x Dissolve in 20mL glycerol, weigh 0.238g potassium bromide and dissolve in 20mL glycerol, add the mixed solution containing potassium bromide dropwise into the glycerol solution of bismuth nitrate pentahydrate , after magnetic stirring for 30 min at room temperature, the mixed solution was transferred to a reaction kettle and reacted in an oven at 160° C. for 16 h, and the precipitate was washed and collected. The precipitate was dried in an oven at 70 °C for 10 h. Weigh 0.2 g of the obtained reactant and add 100 mL of distilled water, hydrolyze at room temperature for 16 h, dry the reaction precipitate at 70 ° C for 10 h, and obtain a solid powder that is Ti 3 C 2 T x / Bi 4 o 5 Br 2 composite photocatalyst.

example 1

[0039] Example 1 Gained Ti 3 C 2 T x / Bi 4 o 5 Br 2 Composite photocatalyst, single Bi 4 o 5 Br 2 The various performance values are listed in Table 1. As can be seen from the table, the catalyst specific surface area prepared in Example 1 is 289m 2 g -1 , the efficiency of nitrogen fixation under visible light is about 2 times that of the monomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com