Silicon modified water-based acrylic emulsion, preparation method and application thereof

A water-based acrylic and silicon modification technology, applied in the direction of coating, can solve the problems of easy hydrolysis, polycondensation, product gelation, low grafting rate, etc., and achieve the effect of good mechanical properties and excellent mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

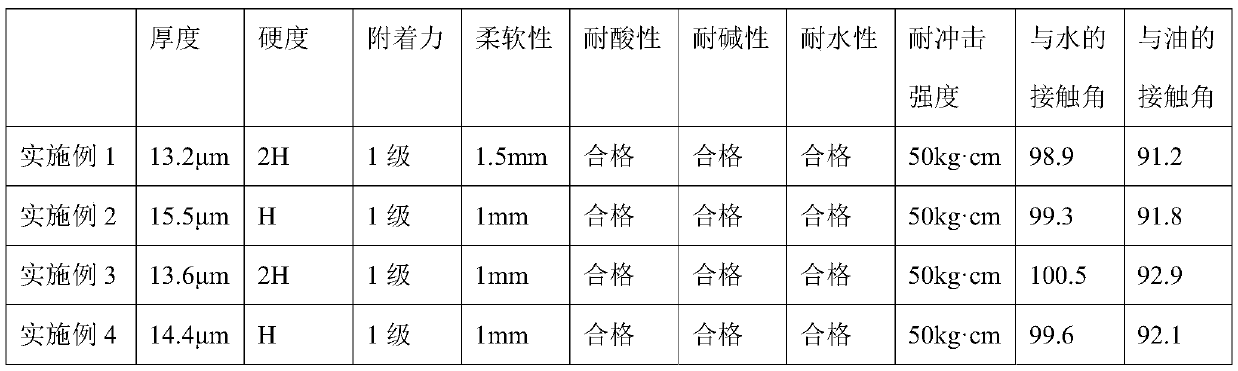

Examples

Embodiment 1

[0052] The present embodiment provides a kind of preparation method of silicon-modified aqueous acrylic acid emulsion, described method comprises the following steps:

[0053] (1) Preparation of modified mesoporous inorganic silica:

[0054] Mix 1g of cetyltrimethylammonium bromide CTAB, 3.5mL of NaOH (2M) and 480mL of deionized water at 80°C, and slowly drop into 5mL of tetraethoxysilane TEOS for 40 minutes. After dripping, keep it warm at 80°C for 2h to obtain a colloid, then centrifuge the obtained colloid, wash with absolute ethanol and water for 3 times, and bake at 80°C for 12h to obtain silicon dioxide (SiO 2 );

[0055] In order to remove the templating agent, the obtained silicon dioxide is dispersed in the dehydrated ethanol solution of concentrated hydrochloric acid, the mass volume ratio of silicon dioxide and the dehydrated ethanol solution of concentrated hydrochloric acid is 20mg / ml, and the dehydrated alcohol solution of the concentrated hydrochloric acid is ...

Embodiment 2

[0062] The present embodiment provides a kind of preparation method of silicon-modified aqueous acrylic acid emulsion, described method comprises the following steps:

[0063] (1) Preparation of modified mesoporous inorganic silica:

[0064] Mix 1g of cetyltrimethylammonium bromide CTAB, 3.5mL of NaOH (2M) and 480mL of deionized water at 80°C, and slowly drop in 5ml of tetraethoxysilane TEOS for 40 minutes. After dripping, keep it warm at 80°C for 2h to obtain a colloid, then centrifuge the obtained colloid, wash with absolute ethanol and water for 3 times, and bake at 80°C for 12h to obtain silicon dioxide (SiO 2 );

[0065] In order to remove the templating agent, the obtained silicon dioxide is dispersed in the dehydrated ethanol solution of concentrated hydrochloric acid, the mass volume ratio of silicon dioxide and the dehydrated ethanol solution of concentrated hydrochloric acid is 20mg / ml, and the dehydrated alcohol solution of the concentrated hydrochloric acid is Th...

Embodiment 3

[0072] The present embodiment provides a kind of preparation method of silicon-modified aqueous acrylic acid emulsion, described method comprises the following steps:

[0073] (1) Preparation of modified mesoporous inorganic silica:

[0074] Mix 1g of cetyltrimethylammonium bromide CTAB, 4mL of NaOH (2M) and 480mL of deionized water at 80°C, and slowly drop into 5ml of tetraethoxysilane TEOS for 40 minutes. After dripping, keep it warm at 80°C for 2h to obtain a colloid, then centrifuge the obtained colloid, wash with absolute ethanol and water for 3 times, and bake at 80°C for 12h to obtain silicon dioxide (SiO 2 );

[0075] In order to remove the templating agent, the obtained silicon dioxide is dispersed in the absolute ethanol solution of concentrated hydrochloric acid, the mass volume ratio of silicon dioxide and the absolute ethanol solution of concentrated hydrochloric acid is 25mg / ml, and the absolute ethanol solution of the concentrated hydrochloric acid is The volu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap