Desertified soil conditioner and preparation method thereof

A technology of soil improver and potassium hydroxide, which is applied in the field of solid waste recycling, can solve the problems of environmental pollution, human health, water source and soil pollution, air pollution, etc., achieve low utilization efficiency, improve soil fertility, and increase utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

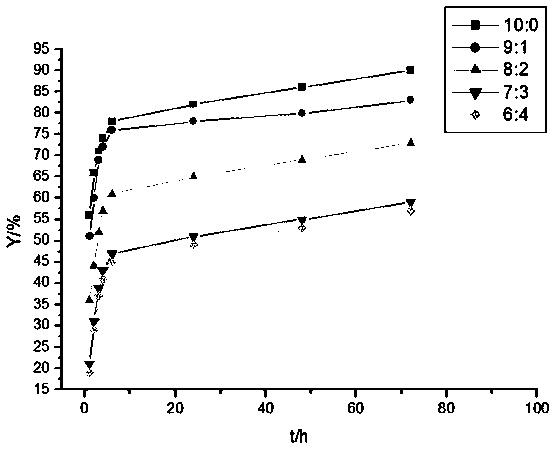

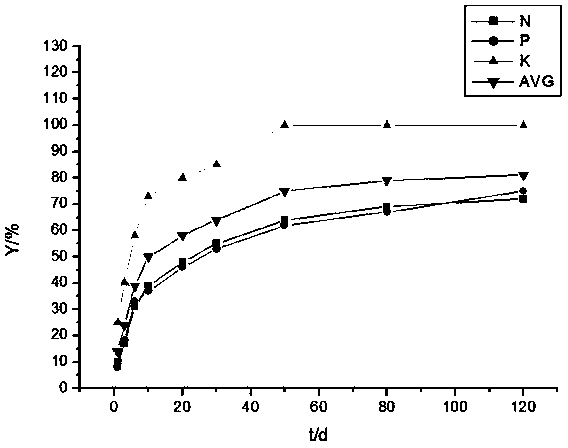

Examples

Embodiment 1

[0023] The gasified coal cinder is discarded after the gasification is completed by Ordos Zhongtian Hechuang GE coal-water slurry gasification device;

[0024] The sandy soil improver of this embodiment is made from the following raw materials in parts by weight: 20 parts of coal gasification ash, 40 parts of plant straw, 1 part of potassium hydroxide, 8 parts of hydroxymethyl cellulose, and 15 parts of animal manure. parts, 0.3 parts of glucose, 0.2 parts of corn flour, and 5 parts of Bacillus subtilis.

[0025] The preparation method of the sandy soil improver of the present embodiment is as follows:

[0026] (1) Crush the plant straw to less than 5mm, mix it evenly with coal gasification ash and hydroxymethyl cellulose, then add it to the aging kettle, add potassium hydroxide solution with a mass fraction of 30%, at 90°C, 1.5-2.0 Under atmospheric pressure, aging for 24 hours;

[0027] (2) Cool the material matured in step (1) to normal temperature, mix evenly with animal...

Embodiment 2

[0035] The sandy soil improver of this embodiment is made from the following raw materials in parts by weight: 40 parts of coal gasification ash, 30 parts of plant straw, 2 parts of potassium hydroxide, 5 parts of hydroxymethyl cellulose, and 20 parts of animal manure. parts, 0.2 parts of glucose, 0.3 parts of corn flour, and 2 parts of Bacillus subtilis.

[0036] The preparation method of the sandy soil improver of the present embodiment is as follows:

[0037] (1) Crush the plant straw to less than 5mm, mix it evenly with coal gasification ash and hydroxymethyl cellulose, then add it to the aging kettle, add potassium hydroxide solution with a mass fraction of 30%, at 110°C, 1.5-2.0 Under atmospheric pressure, aging for 24 hours;

[0038](2) Cool the material matured in step (1) to normal temperature, mix it evenly with animal manure, glucose, corn flour, and Bacillus subtilis, and ferment it for 7 days to obtain a sandy soil improver.

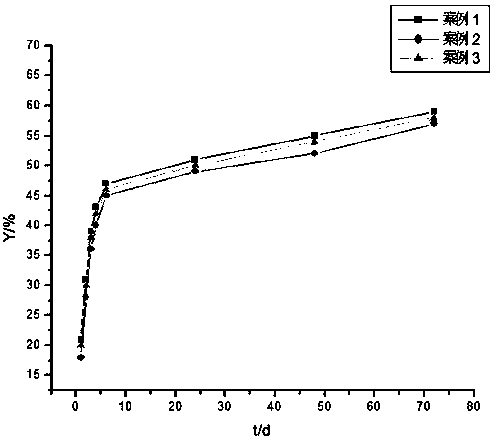

Embodiment 3

[0040] The sandy soil improver of this embodiment is made from the following raw materials in parts by weight: 30 parts of coal gasification ash, 35 parts of plant straw, 1.5 parts of potassium hydroxide, 6 parts of hydroxymethyl cellulose, and 18 parts of animal manure , 0.25 parts of glucose, 0.25 parts of corn flour, 4 parts of Bacillus subtilis.

[0041] The preparation method of the sandy soil improver of the present embodiment is as follows:

[0042] (1) Crush the plant straw to less than 5mm, mix it evenly with coal gasification ash and hydroxymethyl cellulose, then add it to the aging kettle, add potassium hydroxide solution with a mass fraction of 30%, at 100°C, 1.5-2.0 Under atmospheric pressure, aging for 24 hours;

[0043] (2) Cool the material matured in step (1) to normal temperature, mix it evenly with animal manure, glucose, corn flour, and Bacillus subtilis, and ferment for 10 days to obtain a sandy soil improver.

[0044] The experimental results of Case 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com