Ultrasonic-assisted supercritical fluid extraction method for essential oil in cape jasmine leaves

A supercritical fluid, ultrasonic-assisted technology, applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of poor water solubility, low extraction rate, high density of gardenia leaf essential oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

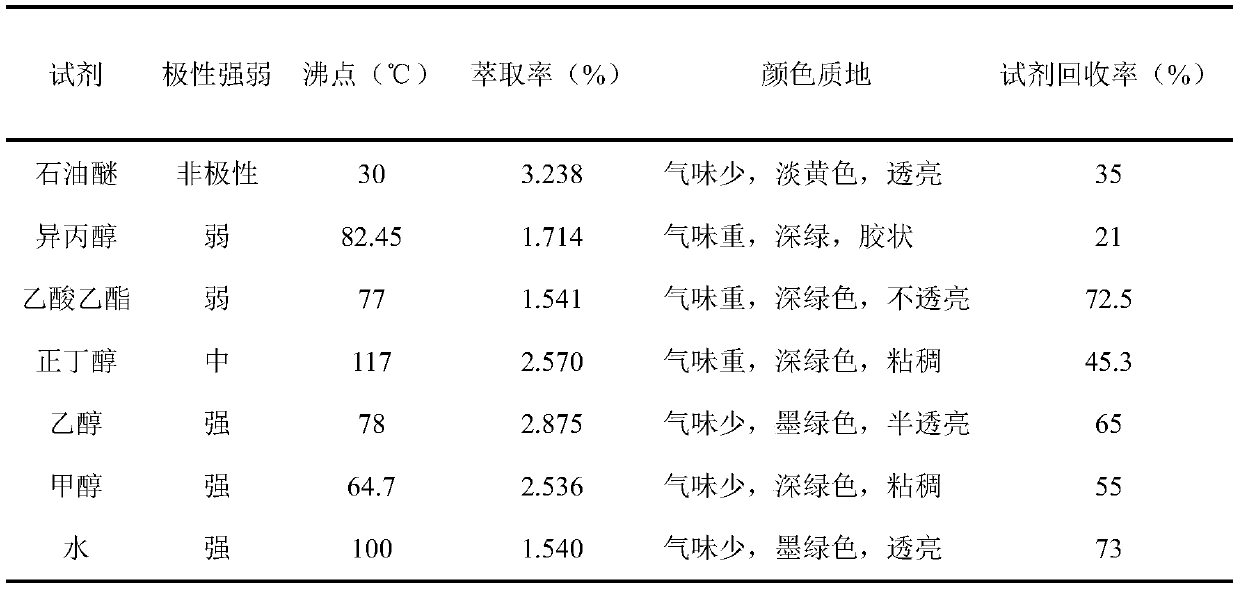

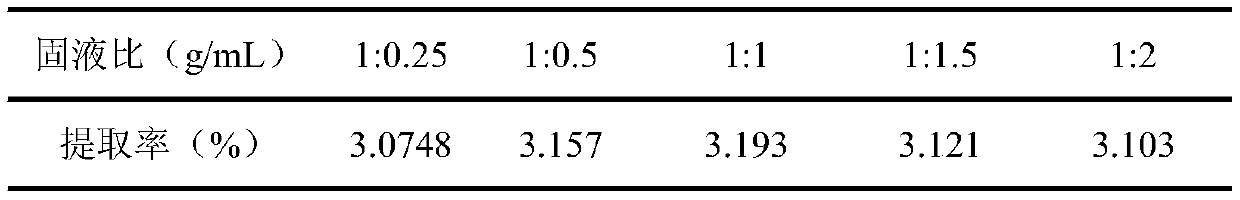

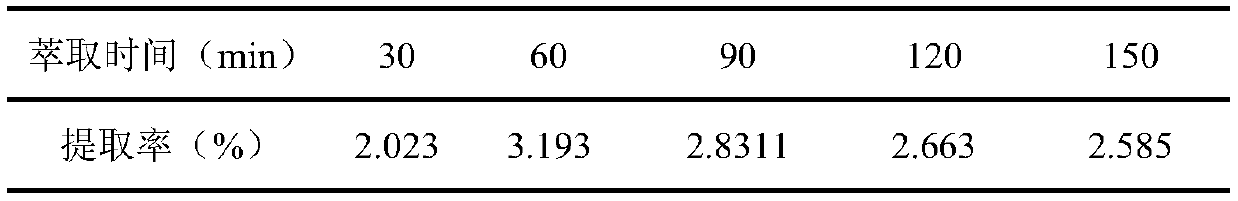

Method used

Image

Examples

Embodiment 1

[0019] 1. Select clean gardenia leaves and freeze-dry them. The drying temperature is -40°C and the drying time is 24 hours. Then, the dried gardenia leaves are crushed with a pulverizer and sieved to 50-60 mesh;

[0020] 2. Weigh an appropriate amount of gardenia leaf powder and mix it with methanol at a ratio of 1:2 (g / mL), place it in a supercritical extraction kettle, and carry out circular extraction under the assistance of ultrasonic waves. The extraction time is 90 minutes, and the extraction temperature is 55°C ;

[0021] 3. After the extraction is completed, the extract is obtained through a separation tank, and concentrated in vacuo at 45° C. to obtain an essential oil mixture.

Embodiment 2

[0023] 1. Select clean gardenia leaves and freeze-dry them. The drying temperature is -50°C and the drying time is 24 hours. Then, the dried gardenia leaves are crushed with a pulverizer and sieved to 50-60 mesh;

[0024] 2. Weigh an appropriate amount of gardenia leaf powder and petroleum ether according to 1:0.8 (g / mL), mix evenly, place in a supercritical extraction kettle, and carry out circular extraction under the assistance of ultrasonic waves. The extraction time is 90 minutes, and the extraction temperature is 40 ℃;

[0025] 3. After the extraction is completed, the extract is obtained through a separation tank, and concentrated in vacuo at 40°C to obtain an essential oil mixture.

Embodiment 3

[0027] 1. Select clean gardenia leaves and freeze-dry them. The drying temperature is -40°C and the drying time is 24 hours. Then, the dried gardenia leaves are crushed with a pulverizer and sieved to 50-60 mesh;

[0028] 2. Weigh an appropriate amount of gardenia leaf powder and mix it with ethanol at a ratio of 1:1 (g / mL), place it in a supercritical extraction kettle, and carry out circular extraction under the assistance of ultrasonic waves. The extraction time is 60 minutes, and the extraction temperature is 45°C ;

[0029] 3. After the extraction is completed, the extract is obtained through a separation tank, and concentrated in vacuo at 55° C. to obtain an essential oil mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com