Strain detection sensor based on graphene film and method of fabricating the same

A graphene thin film, detection sensor technology, applied in the direction of graphene, chemical instruments and methods, electric/magnetic solid deformation measurement, etc., can solve the problems of uncertain number of atomic layers, low concentration of graphene, poor repeatability of experiments, etc., to achieve The effect of controllable process, less wrinkles and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

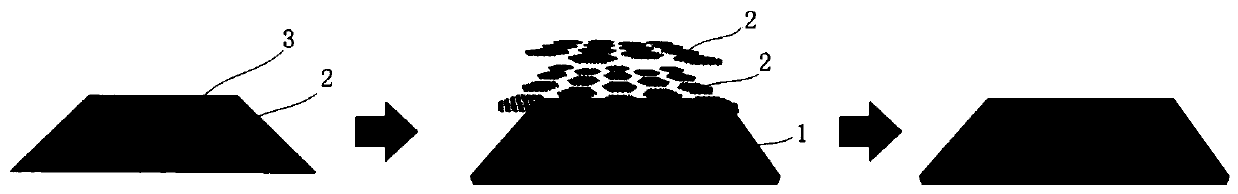

[0044]A strain detection sensor based on a graphene film, such as figure 1 As shown, wherein, the graphene film comprises two layers of graphene monolayer films 2, and the two layers of graphene monolayer films are stacked together. The graphene on the graphene monolayer film 2 is distributed in an island shape. Graphene monolayer film refers to the graphene film containing only one layer of graphene lattice, and the thickness of graphene monolayer film is equivalent to the height of a carbon atom. Graphene is distributed in islands, that is, there is only one discontinuous graphene film on one plane. The graphene single-layer film is non-conductive; after the two-layer graphene single-layer film is stacked, the two graphene single-layer films partially overlap to form a graphene double-layer stack structure, that is, a graphene double-layer film. Due to the tunneling effect of the graphene bilayer film, electrons can jump between the graphene bilayer films, thereby making t...

Embodiment 2~ Embodiment 5

[0061] Embodiments 2 to 5 are the same as Embodiment 1 except that the flow of methane used in step 102 is different. Table 1 lists the methane flow rates used in step 102 in Embodiment 1 to Embodiment 5.

[0062] Table 1 methane flow rate adopted in step 102 in embodiment 1 to embodiment 5

[0063] Example 1 Example 2 Example 3 Example 4 Example 5 Methane flow / sccm 0.95 1.00 1.05 1.10 1.15

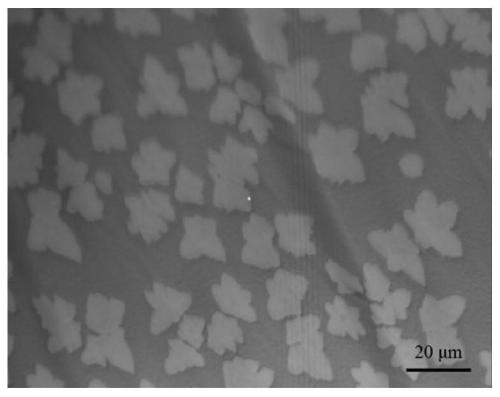

[0064] Figure 3~Figure 7 Respectively be the optical micrograph of the graphene monolayer film that embodiment 1~embodiment 5 prepares. right Figure 3~Figure 7 For comparison: when the methane flow rate is less than 1.0 sccm, the graphene is distributed in an island shape, but the island graphene is relatively sparse; when the methane flow rate is less than 1.0~1.1 sccm, the graphene is distributed in an island shape, and the distribution is uniform and the density is moderate; When the methane flow rate is greater than 1.1 sccm, the island structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com