Carbon-sulfur double doped electrode material and preparation method thereof

A technology of electrode material and sulfur bilayer, which is applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc. Simple preparation process and easy-to-obtain results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Weigh 0.1127g of nickel nitrate and 0.0371g of cobalt nitrate, add 50ml of deionized water and stir until completely dissolved to form a homogeneous solution; weigh 0.3825g of thiourea and 0.0198g of glucose and add to the above solution and stir until completely dissolved to form a homogeneous solution; Cut the cloth into a rectangle of 1 cm×1.5 cm, and ultrasonically clean it with hydrochloric acid, acetone, deionized water, and alcohol for 10 min each.

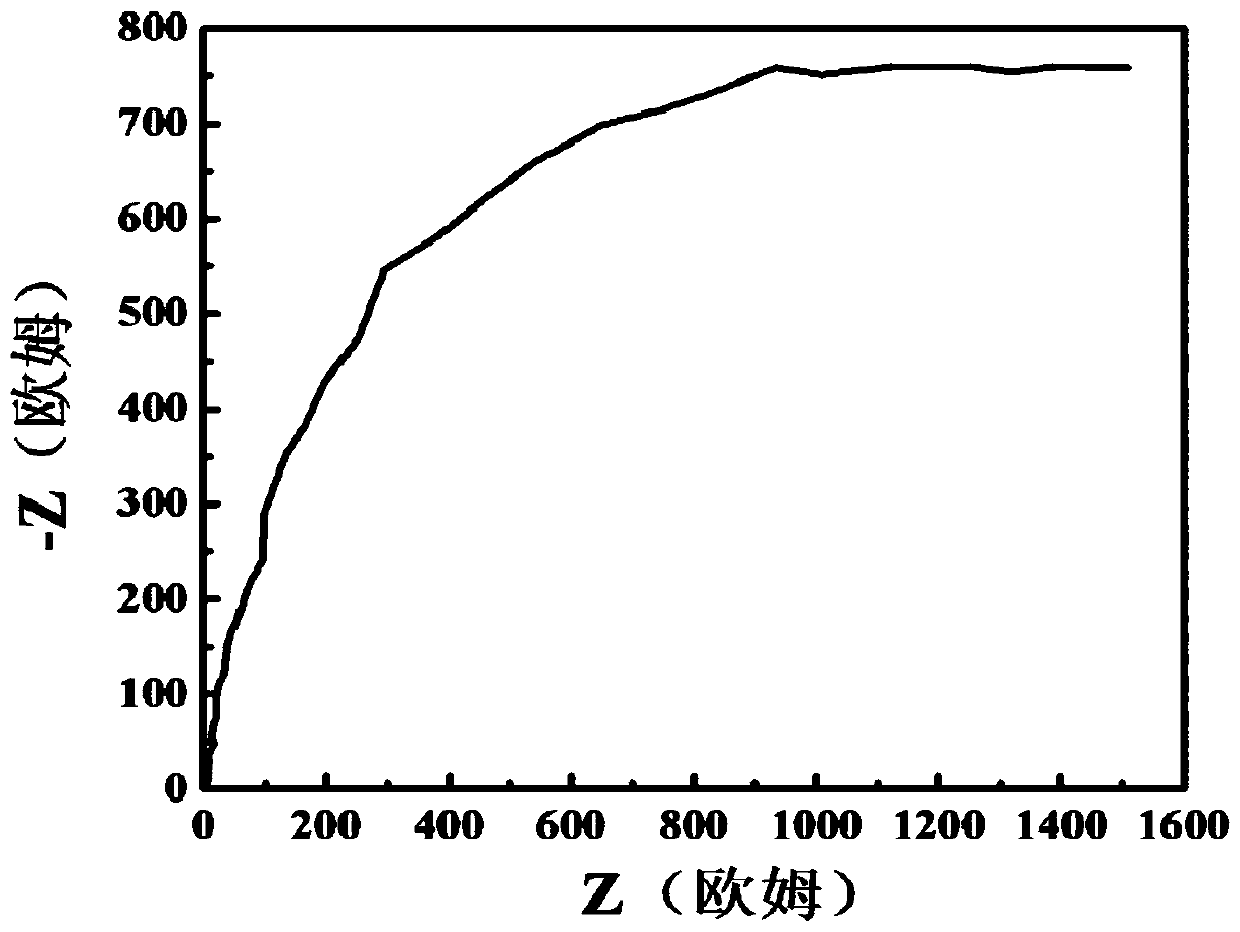

[0049] Constant voltage cathodic electrochemical deposition was used, and the cut and cleaned carbon cloth was used as the conductive substrate. The deposition voltage was -1.5V, Ag / AgCl was used as the reference electrode, and the Pt electrode was used as the counter electrode. The deposition temperature was 20°C. The time is 1200 seconds; a carbon-sulfur double-doped nickel-cobalt double hydroxide electrode material is obtained.

[0050] Take out the deposited nickel-cobalt double hydroxide electrode material, wash...

Embodiment 2

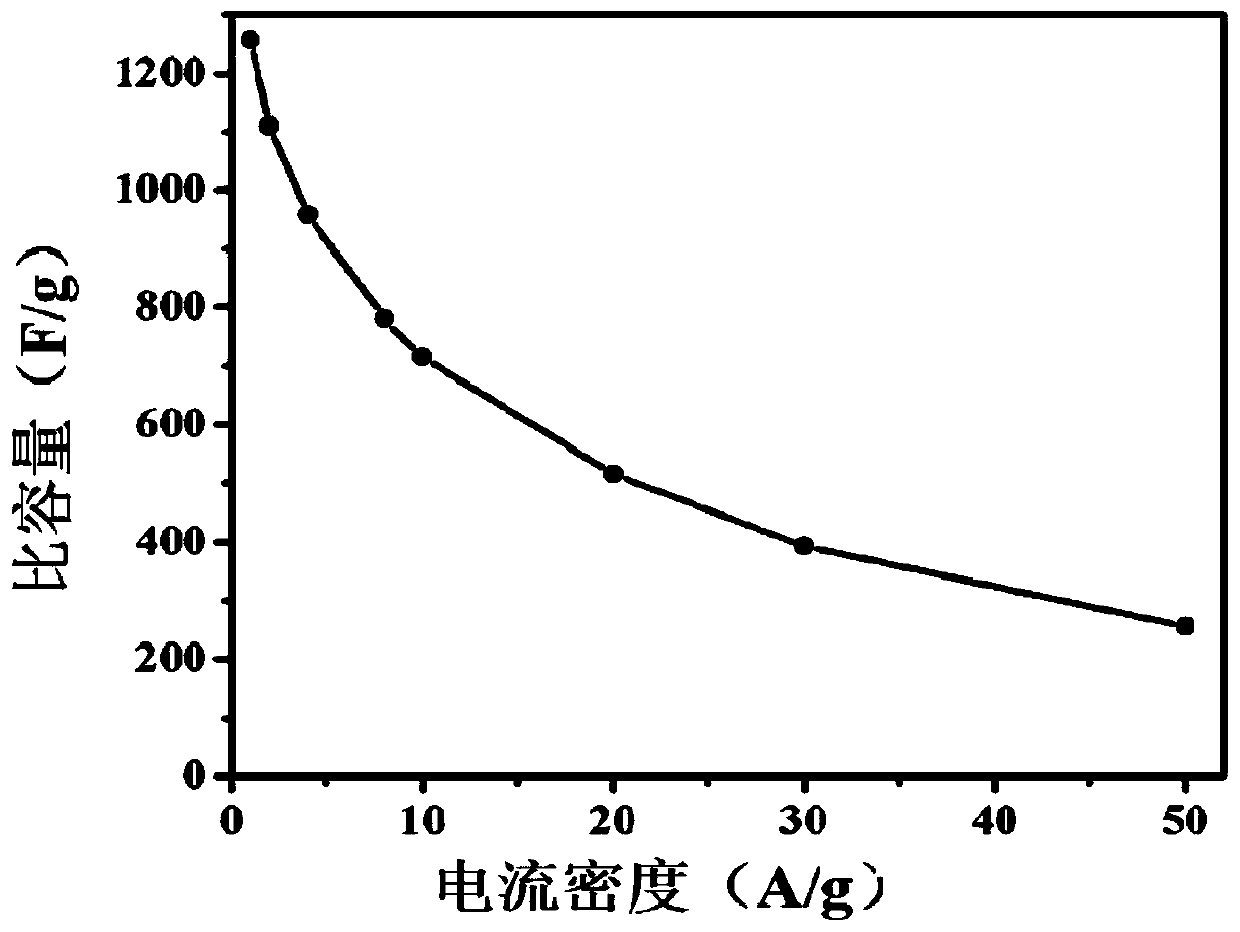

[0053] Weigh 0.1127g of nickel nitrate and 0.0371g of cobalt nitrate, add 50ml of deionized water and stir until completely dissolved to form a homogeneous solution; weigh 0.3825g of thiourea and 0.0991g of glucose and add to the above solution and stir until completely dissolved to form a homogeneous solution; Nickel was cut into a rectangle of 2 cm × 1 cm, and ultrasonically cleaned with hydrochloric acid, acetone, deionized water and alcohol for 10 min each.

[0054] Using constant voltage cathodic electrochemical deposition, the cut and cleaned foamed nickel is used as the conductive substrate, the deposition voltage is -1.5V, Ag / AgCl is used as the reference electrode, and the Pt electrode is used as the counter electrode. The deposition temperature is 35°C and the deposition time is 1800 seconds; obtain the carbon-sulfur double-doped nickel-cobalt double hydroxide electrode material.

[0055] Take out the deposited nickel-cobalt double hydroxide electrode material, rinse...

Embodiment 3

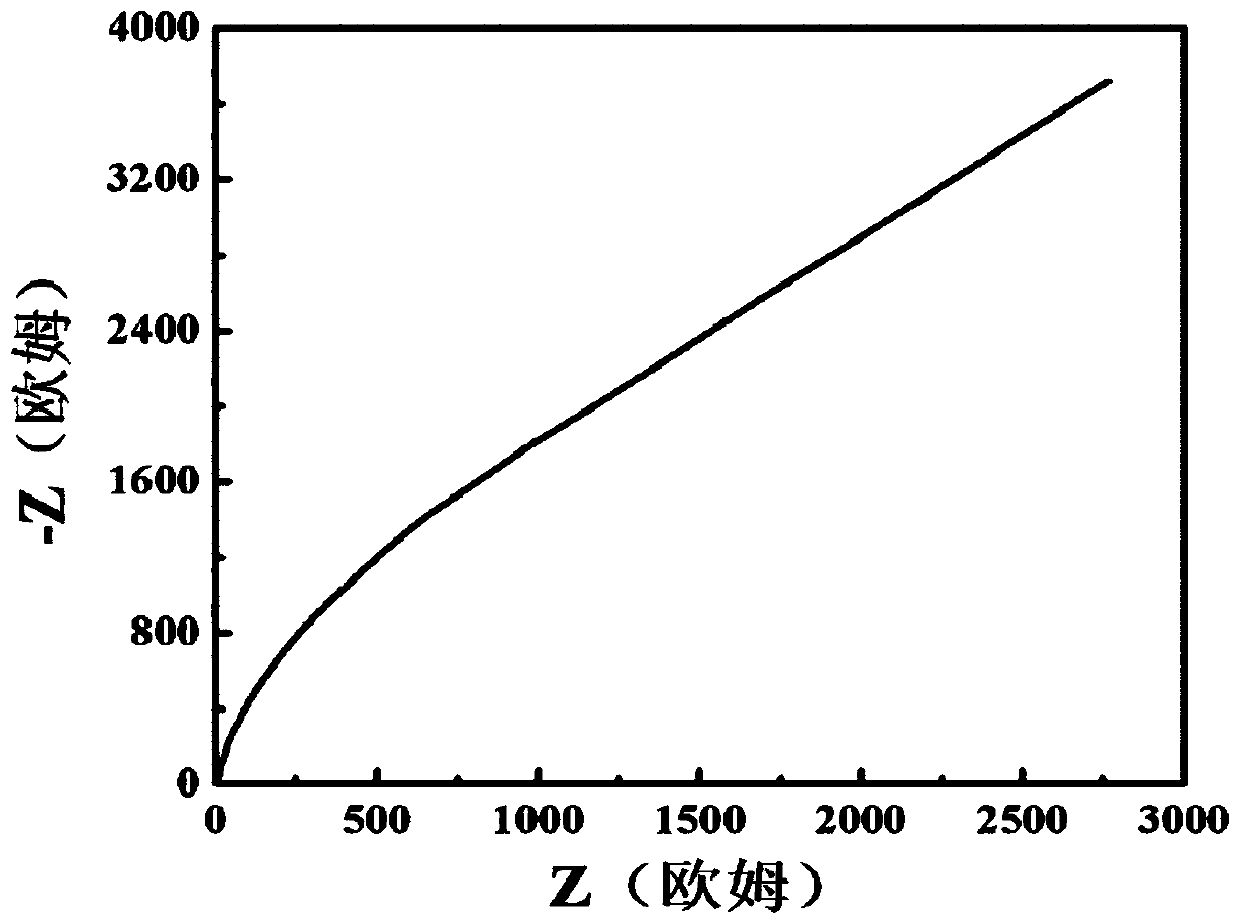

[0058] Weigh 0.0905g of nickel chloride and 0.0301g of cobalt chloride, add 50ml of deionized water and stir until completely dissolved into a homogeneous solution; weigh 0.3825g of thiourea and 0.0049g of glucose into the above solution and stir until completely dissolved into a homogeneous solution; Cut the carbon paper into a rectangle of 2 cm × 1 cm, and ultrasonically clean it with hydrochloric acid, acetone, deionized water, and alcohol for 10 min each.

[0059] Constant voltage cathodic electrochemical deposition was used, and the cut and cleaned carbon paper was used as the conductive substrate. The deposition voltage was -1V, Ag / AgCl was used as the reference electrode, and the Pt electrode was used as the counter electrode. The deposition temperature was 50 °C and the deposition time was 1800 °C. Seconds, a carbon-sulfur double-doped nickel-cobalt double hydroxide electrode material is obtained.

[0060] Take out the deposited nickel-cobalt double hydroxide electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com