A method for removing silicon nitride in radio frequency ldmos planarization process

A planarization process, silicon nitride technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of difficult corrosion, increase the corrosion time, increase the thickness loss of the buffer oxide layer, etc., achieve uniform removal, improve Device performance, buffer oxide loss controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

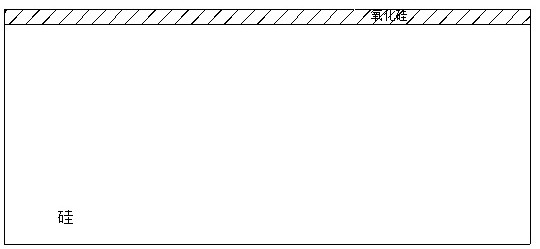

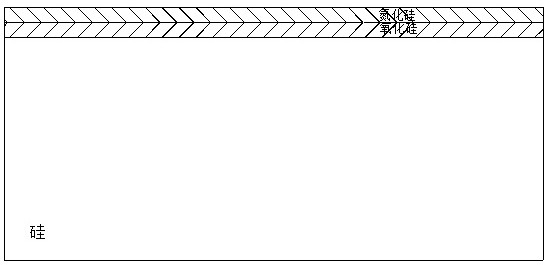

[0049] (1) Oxidative growth of 1000Å first buffer SiO on the surface of the wafer 2 layer;

[0050] (2) Deposit 1500Å Si on the surface of the buffer oxide layer by LPCVD 3 N 4 ;

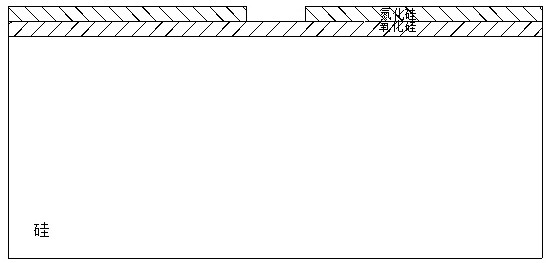

[0051] (3) Photolithography, dry etching surface Si 3 N 4 , SiO 2 , terminated in buffered SiO 2 layer; remove the photoresist to form an oxide window;

[0052] (4) HF: H 2 O=1:10 concentration HF corrosion buffer SiO 2 layer for 3 minutes until the surface is hydrophobic;

[0053] (5) Perform the first wet oxygen oxidation with a thickness of 9800Å;

[0054] (6) Buffered hydrofluoric acid corrodes the first wet oxygen SiO 2 layer, time 10 minutes, surface hydrophobic;

[0055] (7) Oxidative growth of the second buffer SiO 2 Layer thickness is 800 Å;

[0056] (8) In buffered SiO 2 LPCVD deposited Si on the surface of the layer 3 N 4 , with a thickness of 800 Å;

[0057] (9) Dry etching of Si deposited by LPCVD 3 N 4 , Si at the oxidation window 3 N 4 Etched clean, active Si 3 ...

Embodiment 2

[0062] (1) Oxidative growth of 1000Å first buffer SiO on the surface of the wafer 2 layer;

[0063] (2) Deposit 1510Å Si on the surface of buffer oxide layer 1 by LPCVD 3 N 4 ;

[0064] (3) Photolithography, dry etching surface Si 3 N 4 , SiO 2 , terminated in buffered SiO 2 layer; remove the photoresist to form an oxide window;

[0065] (4) HF: H 2 O=1:10 concentration HF corrosion buffer SiO 2 layer for 3 minutes until the surface is hydrophobic;

[0066] (5) Perform the first wet oxygen oxidation with a thickness of 9885Å;

[0067] (6) Buffered hydrofluoric acid corrodes the first wet oxygen SiO 2 layer, time 10 minutes, surface hydrophobic;

[0068] (7) Oxidative growth of the second buffer SiO 2 Layer thickness is 500 Å;

[0069] (8) In buffered SiO 2 LPCVD deposited Si on the surface of the layer 3 N 4 , with a thickness of 800 Å;

[0070] (9) Dry etching of Si deposited by LPCVD 3 N 4 , Si at the oxidation window 3 N 4 Etched clean, active Si 3 N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com