Device for preparing methanol into propylene

A technology for producing propylene and methanol from methanol, applied in chemical instruments and methods, ether preparation, sustainable manufacturing/processing, etc., can solve the problems of increasing C4 cycle energy consumption and heater load, affecting propylene yield, and olefin waste, etc. Achieve the effects of efficient temperature control and stability, increase olefin content, and reduce fluctuations in propylene yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

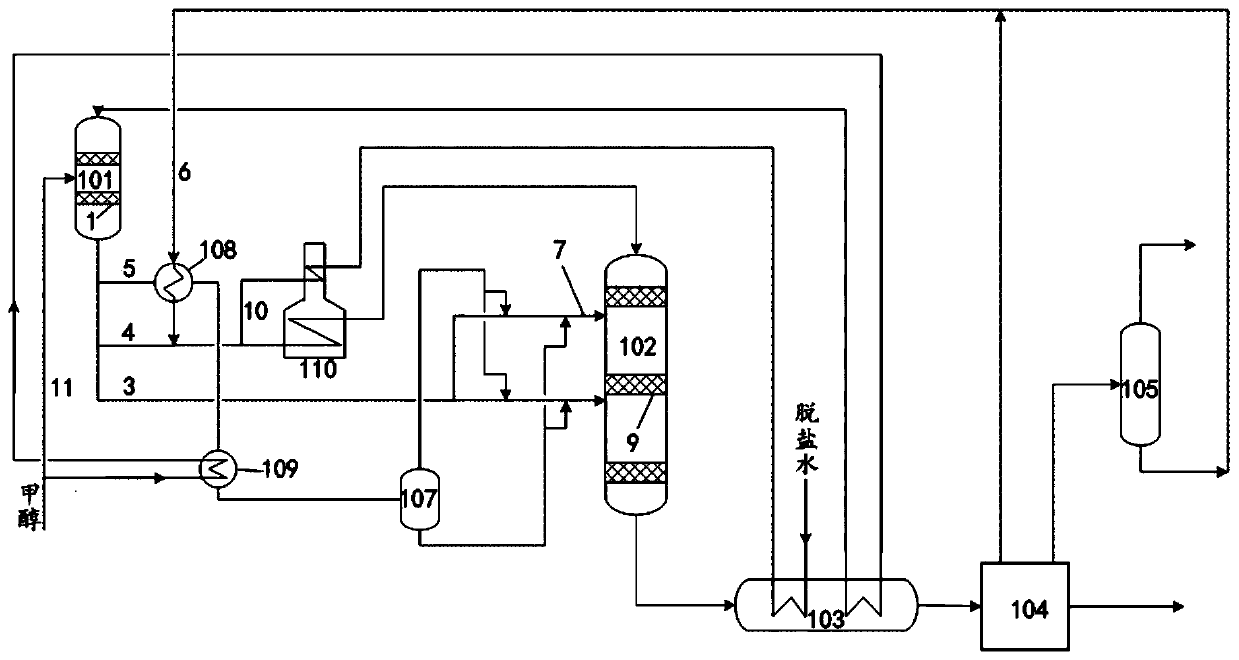

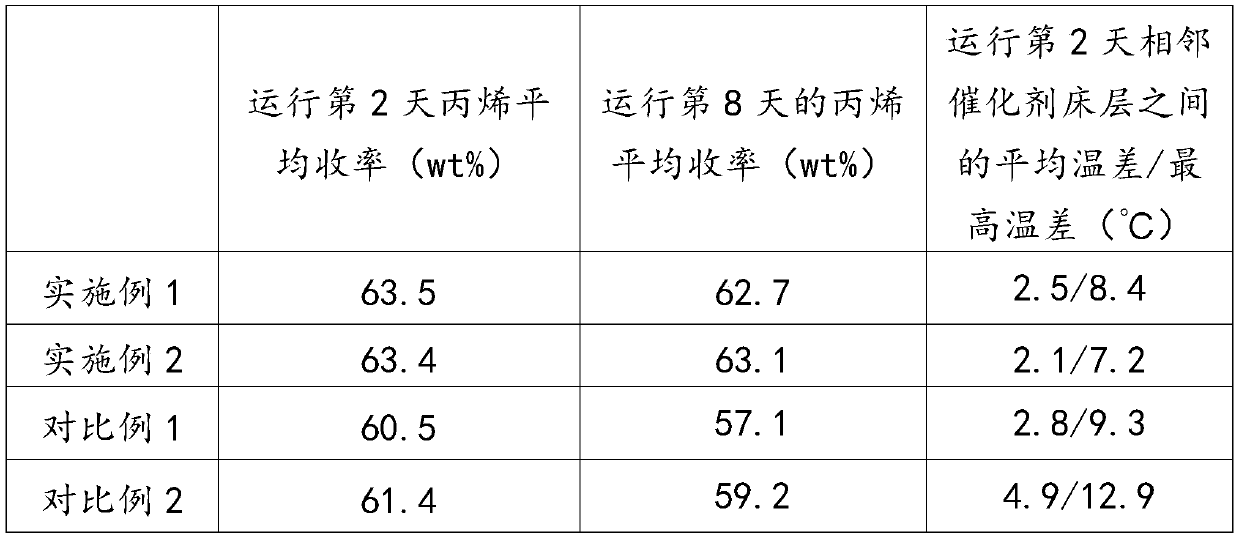

[0060] use as figure 1 Experiments are carried out in the simulated device shown, wherein the catalyst in the first reactor 101 (i.e. DME reactor) is γ-Al 2 o 3 (Select the DME-1 catalyst of Clariant Co., Ltd.), and fill in two layers. The second reactor 102 is provided with five layers of catalyst beds 9, and the catalysts are evenly packed into the first to fifth catalyst beds of the second reactor 102, wherein the distance between the catalyst beds is from the upper right to The lower gradually increases (the distance between any intermediate catalyst bed and the adjacent catalyst bed below it is 1.1 times the distance between the adjacent catalyst bed above it).

[0061]Wherein, the feed amount of fresh methanol to the first reactor 101 is 2.5kg / h, and the total amount of catalyst loaded in the first reactor is 1.8kg, and the reaction pressure is 0.8MPa. After the fresh methanol accounting for 60wt% of the total amount is preheated to about 270°C, it enters from the top...

Embodiment 2

[0065] The difference from Example 1 is that in the first product stream obtained, the first product stream accounting for (10±1)wt% is transported through the second feed pipe 4, and the first product flow accounting for (57±1)wt% The first product stream is conveyed through the third conveying pipe 3 and the remainder is conveyed through the first conveying pipe 5 . The temperature of the liquid phase from the separation column 107 is further controlled at 55±2°C. At the same time, the distance between any intermediate catalyst bed in the second reactor 102 and the adjacent catalyst bed below it is 1.2 times the distance between the adjacent catalyst bed above it. The experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com