Alcohol soluble high-ionic selective negative ion exchange membrane, preparation method thereof and application of exchange membrane

An anion-exchange membrane and ion-selective technology, applied in anion exchange, ion exchange, chemical instruments and methods, etc., to achieve the effects of inhibiting water absorption and swelling, broad application prospects, high economic benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

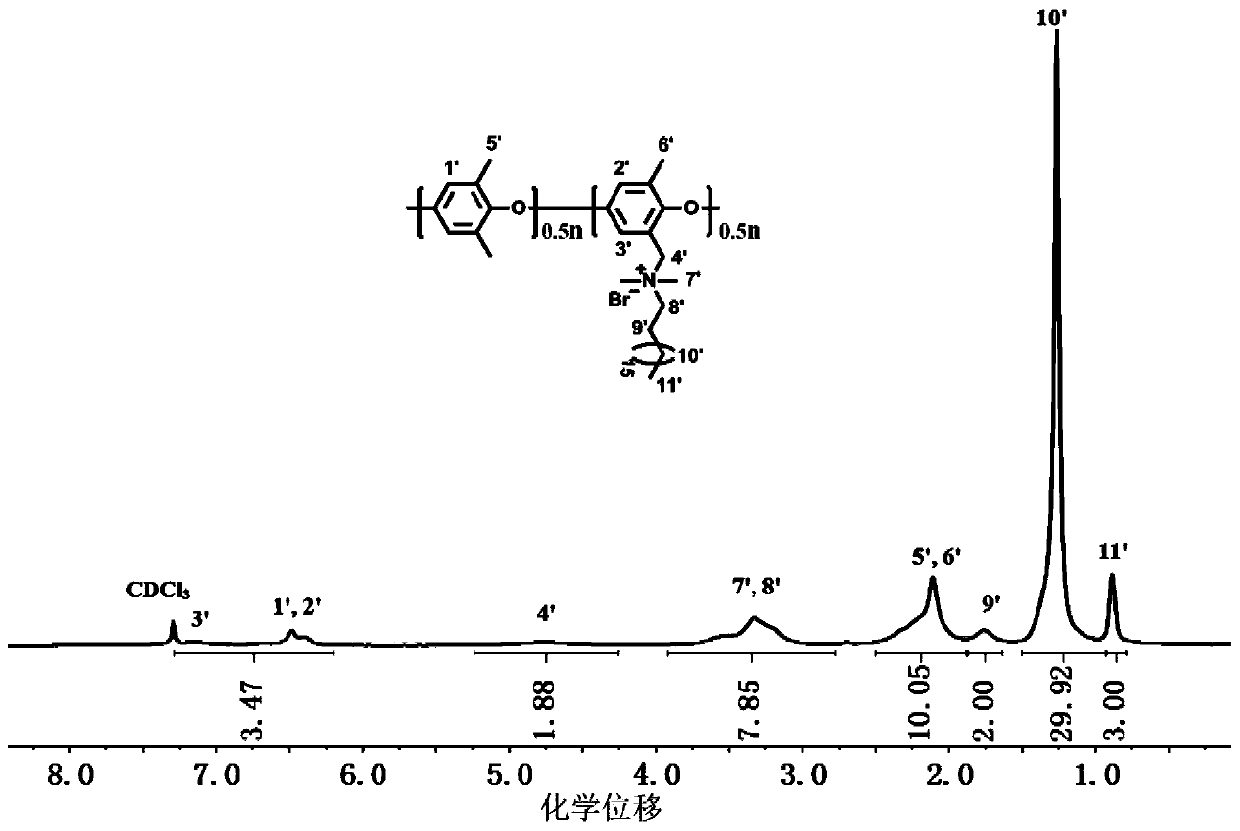

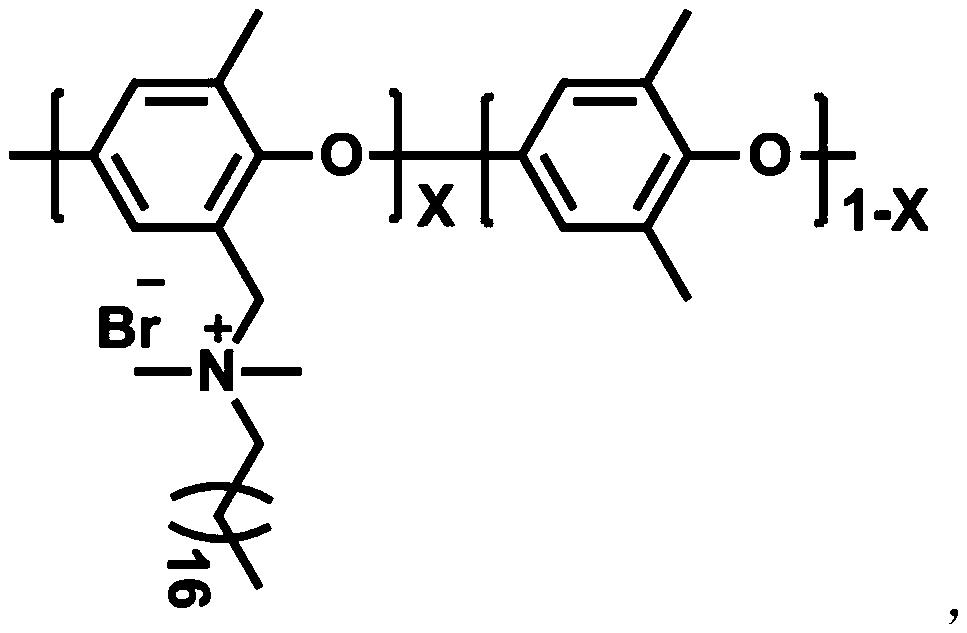

[0030] (1) Preparation of long hydrophobic alkyl side chain tadpole polyphenylene ether ionomer PPO-DMODA-A:

[0031] Dissolve 9g of PPO (75mmol of repeating unit) in 100mL of chlorobenzene, add N-bromosuccinimide NBS (5.34g, 30mmol) and azoisobutyronitrile AIBN (0.33g, 2mmol), and react at 135°C 3h, the reaction solution 1 was obtained, and the reaction solution 1 was cooled to room temperature and dropped into 1000mL methanol to obtain a light yellow precipitate, which was washed with methanol and dried to obtain a crude product, which was dissolved in dichloromethane and prepared The mass fraction is 10% mixed solution, and 100mL acetone is slowly added into the mixed solution to obtain light yellow particles, which are pure bromomethylated PPO, i.e. BPPO, and the degree of bromination x=0.3; the obtained 1.42 g BPPO (3 mmol moles of bromomethyl) was dissolved in 27 mL of N-methylpyrrolidone, N,N-dimethyloctadecylamine (3 mmol, 0.89 g) was added, and reaction solution 2 was...

Embodiment 2

[0036] (1) Preparation of long hydrophobic alkyl side chain tadpole polyphenylene ether ionomer PPO-DMODA-B:

[0037] Dissolve 9 g of PPO (75 mmol of repeating unit) in 100 mL of chlorobenzene, add N-bromosuccinimide NBS (6.67 g, 37.5 mmol) and azoisobutyronitrile AIBN (0.41 g, 2.5 mmol), at 135 °C React for 3 hours to obtain reaction solution 1. Cool the reaction solution 1 to room temperature and drop into 1000mL methanol to obtain a light yellow precipitate. The light yellow precipitate is washed with methanol and dried to obtain a crude product. The crude product is dissolved in dichloromethane Finally, a mixed solution with a mass fraction of 10% was prepared, and 100 mL of acetone was slowly added to the mixed solution to obtain light yellow particles, which were pure bromomethylated PPO, i.e. BPPO, and the degree of bromination x=0.4; The obtained 1.5g BPPO (the bromomethyl mole number is 4mmol) was dissolved in 31mL N-methylpyrrolidone, N,N-dimethyloctadecylamine (4mmo...

Embodiment 3

[0042] (1) Preparation of long hydrophobic alkyl side chain tadpole polyphenylene ether ionomer PPO-DMODA-C:

[0043] Dissolve 9g of PPO (75mmol of repeating unit) in 100mL of chlorobenzene, add N-bromosuccinimide NBS (8.01g, 45mmol) and azoisobutyronitrile AIBN (0.49g, 3mmol), and react at 135°C 3h, the reaction solution 1 was obtained, and the reaction solution 1 was cooled to room temperature and dropped into 1000mL methanol to obtain a light yellow precipitate, which was washed with methanol and dried to obtain a crude product, which was dissolved in dichloromethane and prepared The mass fraction is 10% mixed solution, and 100mL acetone is slowly added into the mixed solution to obtain light yellow particles, which are pure bromomethylated PPO, i.e. BPPO, and the degree of bromination x=0.5; the obtained 1.58 g BPPO (the bromomethyl molarity is 5 mmol) was dissolved in 35 mL of N-methylpyrrolidone, N,N-dimethyloctadecylamine (5 mmol, 1.49 g) was added, and reaction solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com