Preparation method of elastic eraser material

A technology of elastic eraser and elastic body, which is applied in the direction of eraser, printing, office supplies, etc., can solve the problems of poor elasticity and fracture of the eraser, and achieve the effect of good cold resistance, low heat generation, and excellent low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

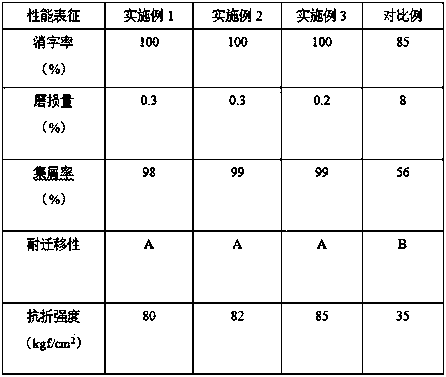

Examples

Embodiment Construction

[0025] In parts by weight, respectively weigh 50-60 parts of thermoplastic polyurethane elastomer, 20-30 parts of styrene butadiene rubber, and 1 to 5 parts of white carbon black. Mix the thermoplastic polyurethane elastomer and styrene butadiene rubber in an internal mixer. , Mix 6-10min at a temperature of 160~170℃ and a stirring speed of 300~500r / min to obtain Mixture A. Add white carbon to Mix A and continue mixing for 10~20min to obtain Mixture B. Place the mixture B in a flat vulcanizer, preheat it at a temperature of 160~170℃ for 10~15min, then press it at a temperature of 160~170℃ and a pressure of 15~20MPa for 10~15min, and cool it to room temperature. Obtain modified styrene-butadiene rubber; in parts by weight, respectively weigh 40-60 parts of modified styrene-butadiene rubber, 50-70 parts of butadiene rubber, 50-60 parts of plasticizer epoxy soybean oil, 20-30 parts Filler white carbon black, 1 to 5 parts of stabilizer calcium stearate, 0.2 to 0.5 parts of lubrican...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com