Nano TiO2 modified EPDM (ethylene propylene diene monomer) and preparation method thereof

A nano-modified technology, which is applied in the field of nano-TiO2 modified EPDM and its preparation, can solve the problems of insufficient application and less research, and achieve the effect of improving tear strength and toughness and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

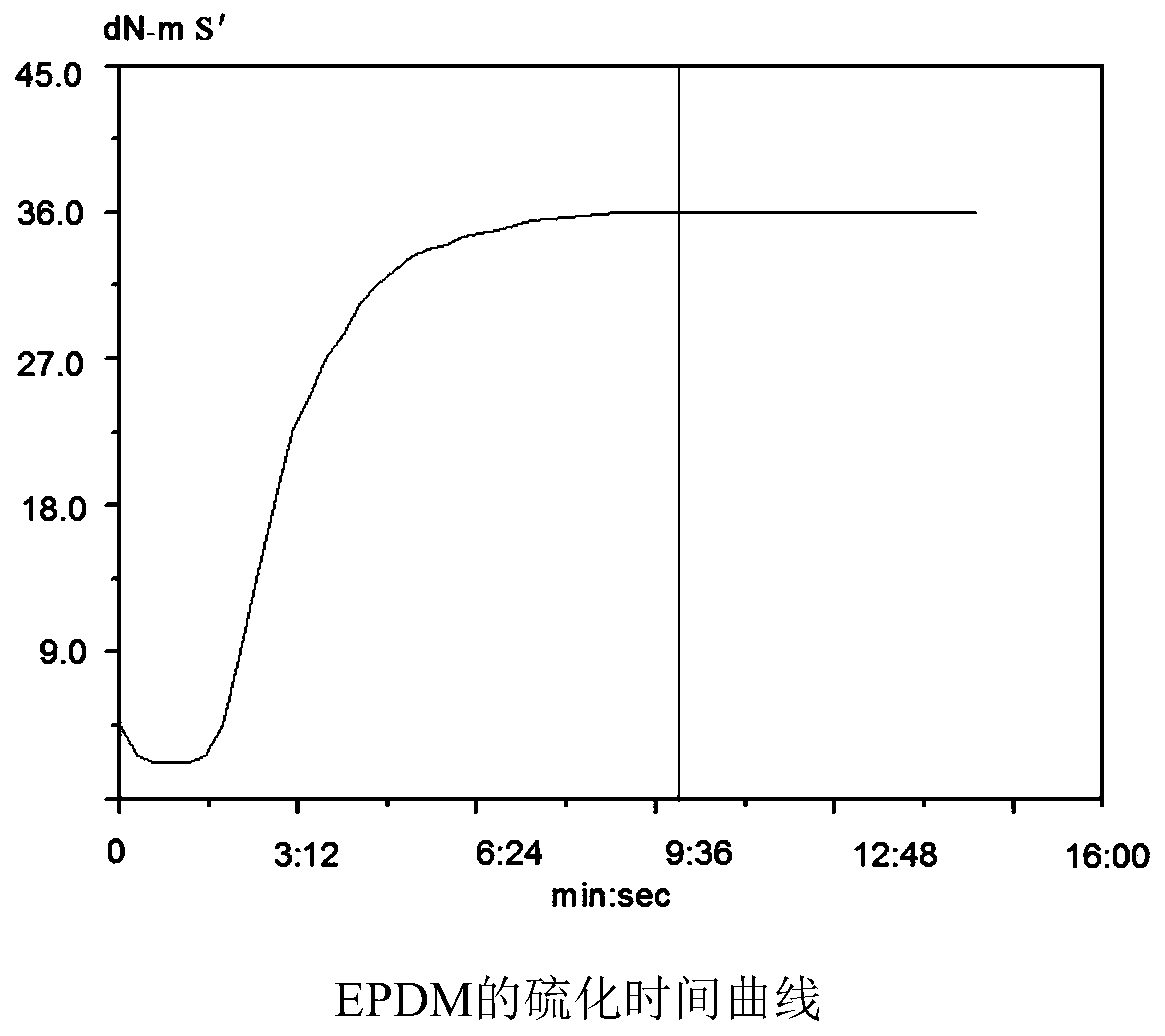

Image

Examples

Embodiment 1

[0036] Nano-TiO 2 The modified EPDM includes the following components in parts by mass: 400 parts of EPDM, 9 parts of zinc oxide, 4 parts of stearic acid, 6 parts of sulfur, and 6 parts of accelerator.

[0037] The nano-TiO 2 The preparation method of modified EPDM is as follows:

[0038] Step 1: Weigh 400 parts of EPDM, 9 parts of zinc oxide, 4 parts of stearic acid, 6 parts of sulfur, and 6 parts of accelerator (weighed according to the mixture of TMTD and M with a mass ratio of 2:1), and set aside.

[0039] Step 2: Roll the weighed EPDM 3~4 times (roll distance 0.5~1.0mm), and turn over (using the method of triangular wrapping and rolling), until a smooth and non-porous roll-wrapped rubber layer is formed. Start refining, add zinc oxide, stearic acid, accelerator and sulfur in sequence, adjust the roller distance, and continue refining until the components are mixed until the color is uniform and the surface is smooth;

[0040] Step 3: Adjust the roller distance, make a ...

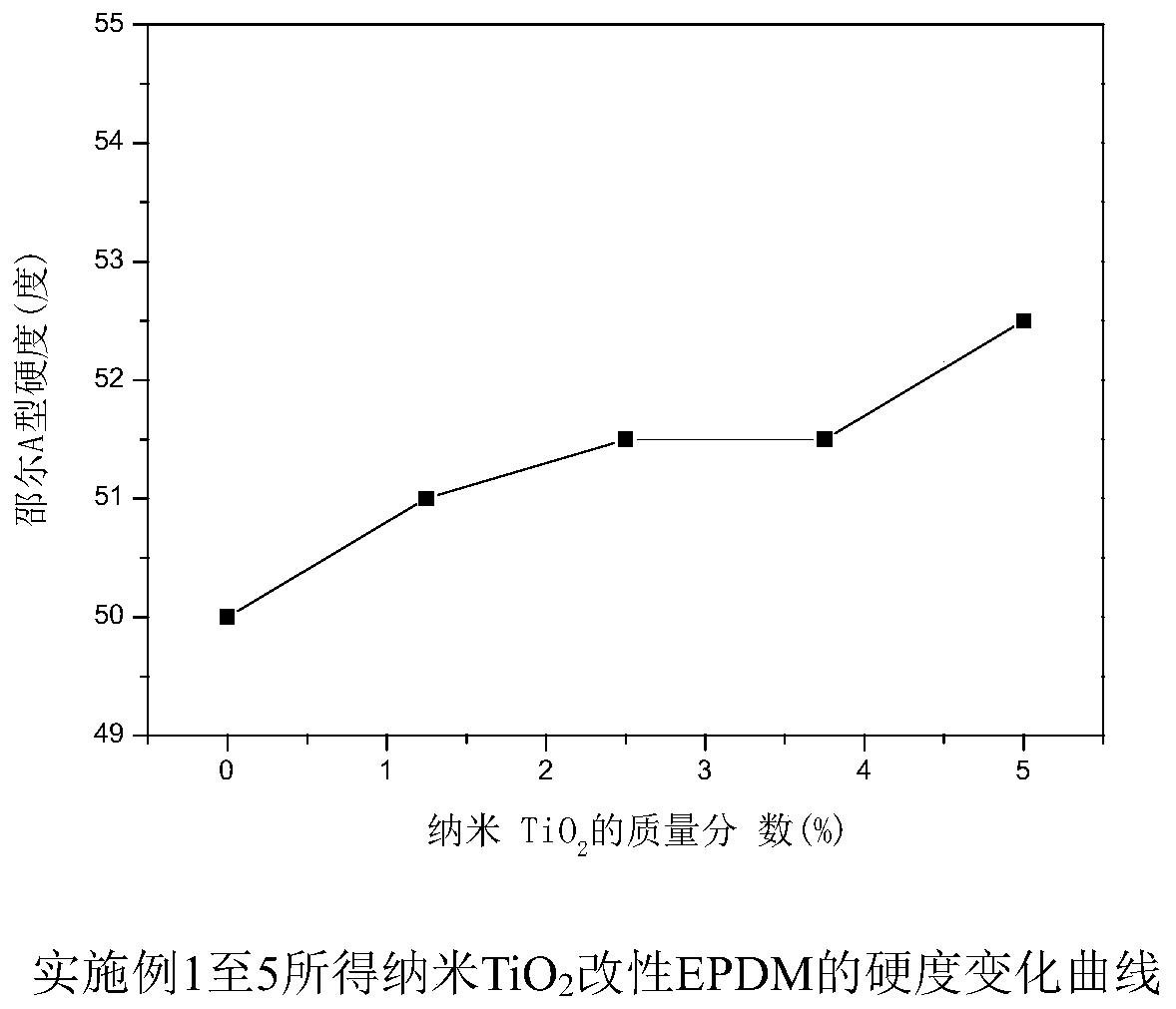

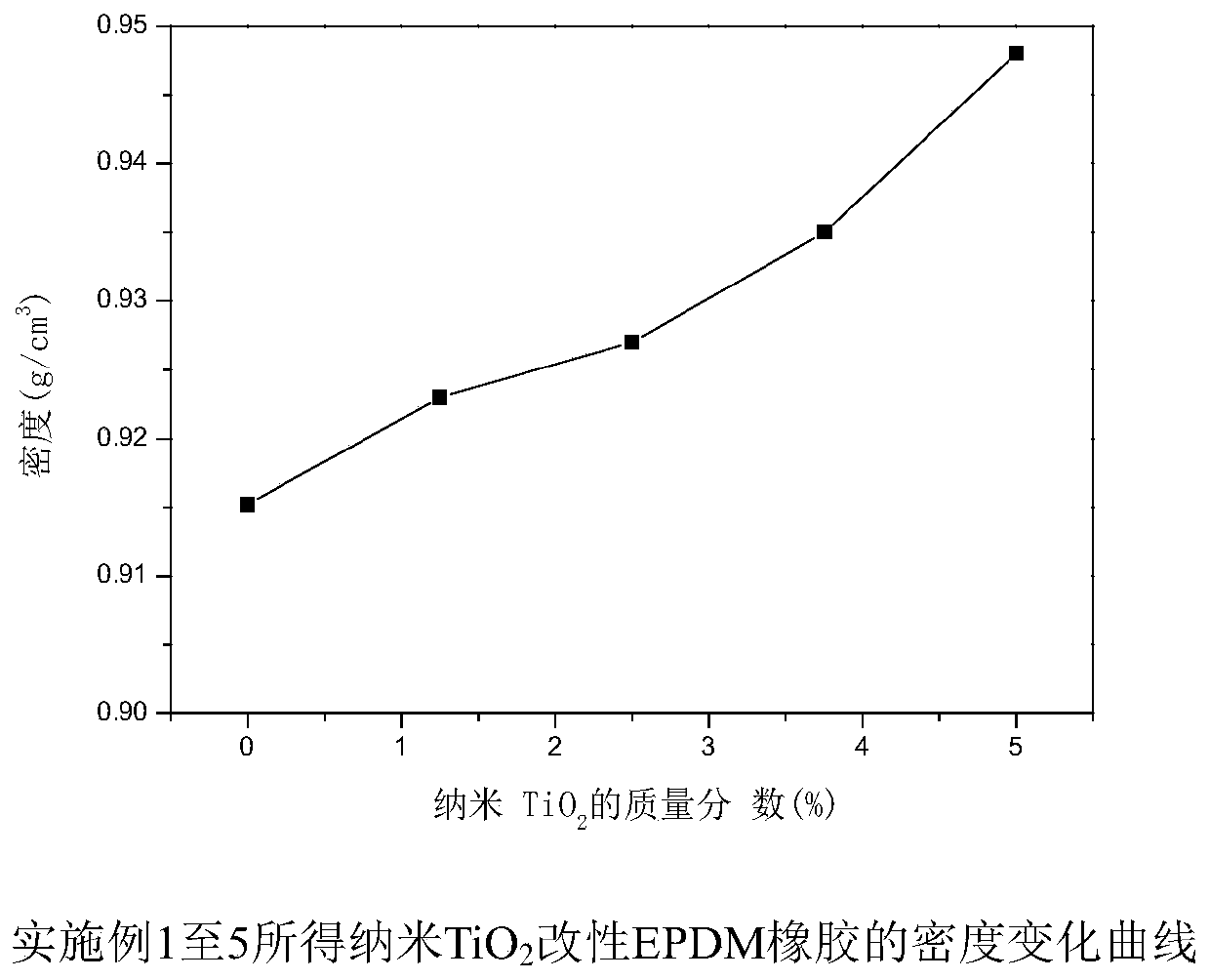

Embodiment 2

[0044] Nano-TiO 2 Modified EPDM, including the following components in parts by mass: nano TiO 2 1.25 parts, EPDM 400 parts, zinc oxide 9 parts, stearic acid 4 parts, sulfur 6 parts, accelerator 6 parts.

[0045] The nano-TiO 2 The preparation method of modified EPDM is as follows:

[0046] Step 1: Weigh nano TiO by mass 2 1.25 parts (particle size is 20nm), 400 parts of EPDM, 9 parts of zinc oxide, 4 parts of stearic acid, 6 parts of sulfur, 6 parts of accelerator (weighed according to the mixture of TMTD and M with a mass ratio of 2:1), set aside.

[0047] Step 2: Roll the weighed EPDM 3~4 times (roll distance 0.5~1.0mm), and turn over (using the method of triangular wrapping and rolling), until a smooth and non-porous roll-wrapped rubber layer is formed. Start refining, add zinc oxide, stearic acid, accelerator, nano-TiO in sequence 2 and sulfur, adjust the roller distance, and continue to smelt until the components are mixed until the color is uniform and the surface is...

Embodiment 3

[0052] Nano-TiO 2 Modified EPDM, including the following components in parts by mass: nano TiO 2 0~20 parts, EPDM 350~450 parts, zinc oxide 5~25 parts, stearic acid 1-7 parts, sulfur 2-10 parts, accelerator 2-10 parts.

[0053] The nano-TiO 2 The preparation method of modified EPDM is as follows:

[0054] Step 1: Weigh nano TiO by mass 2 2.5 parts (particle size is 20nm), 400 parts of EPDM, 9 parts of zinc oxide, 4 parts of stearic acid, 6 parts of sulfur, 6 parts of accelerator (weighed according to the mixture of TMTD and M with a mass ratio of 2:1), set aside.

[0055] Step 2: Roll the weighed EPDM 3~4 times (roll distance 0.5~1.0mm), and turn over (using the method of triangular wrapping and rolling), until a smooth and non-porous roll-wrapped rubber layer is formed. Start refining, add zinc oxide, stearic acid, accelerator, nano-TiO in sequence 2 and sulfur, adjust the roller distance, and continue to smelt until the color of each component is mixed and the surface i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com