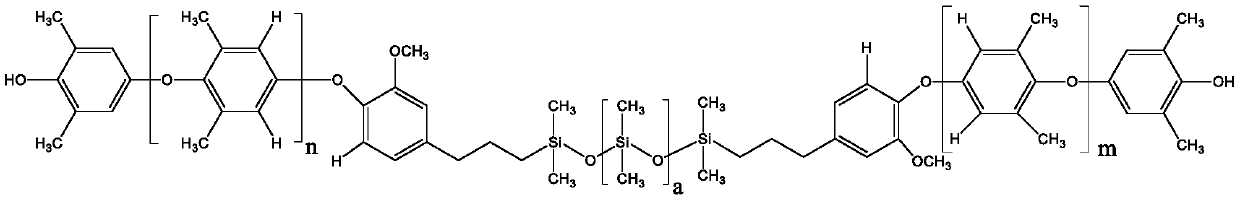

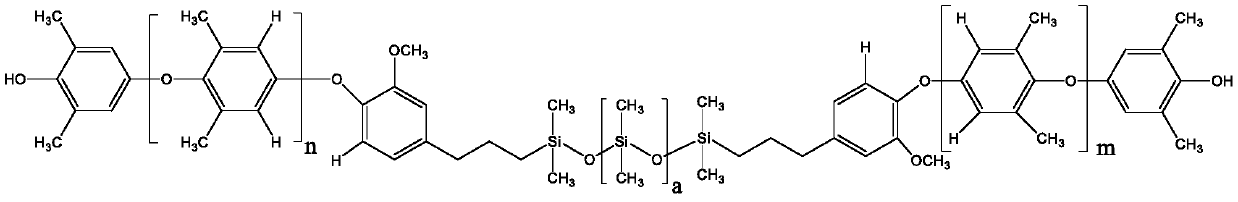

Halogen-free flame-retardant thermoplastic elastomer and preparation method and application thereof

A thermoplastic elastomer, elastomer technology, used in plastic/resin/wax insulators, insulators, rubber insulators, etc., can solve the problems of poor fluidity, low flame retardant carbonization rate, large smoke generation, etc., to improve the uniform dispersion. properties, improved tensile and tear strength, reduced smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

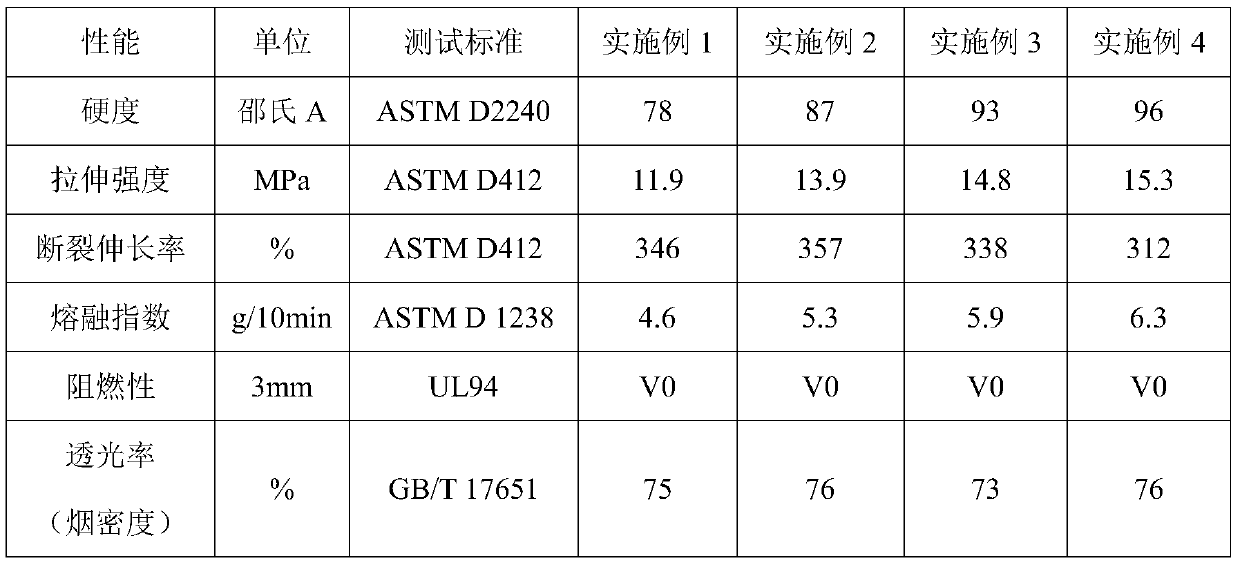

Embodiment 1

[0053] The preparation method of this example halogen-free flame-retardant polyphenylene ether-polysiloxane thermoplastic elastomer is as follows:

[0054] Weigh 25 parts of polyphenylene ether-polysiloxane copolymer with intrinsic viscosity of 0.35dL / g, 25 parts of SEPSYH4052, 10 parts of polypropylene 5090T, 4 parts of compatibilizer A2361, 15 parts of JSL-MC15, 15 parts of FR-ALP, 4 parts of triazine char-forming agent PPM Triazine HF, 15 parts of 32# white oil, 2 parts of oleic acid amide, and 1 part of antioxidant 1010.

[0055] First put SEPS elastomer and 32# white oil into the high-speed mixer in proportion, start stirring for 3 minutes, then add the remaining polyphenylene ether-polysiloxane copolymer, polypropylene 5090T, compatibilizer A2361, compound halogen-free Flame retardant, char forming agent, oleic acid amide, and antioxidant 1010 are put into the high-speed mixer in proportion, and the speed is 750r / min, and the premix is obtained after fully mixing. Add...

Embodiment 2

[0057] The preparation method of this example halogen-free flame-retardant polyphenylene ether-polysiloxane thermoplastic elastomer is as follows:

[0058] Weigh 30 parts by mass of polyphenylene ether-polysiloxane copolymer with an intrinsic viscosity of 0.35dL / g, 20 parts of SEBSYH502T, 10 parts of polypropylene 5090T, 5 parts of polyethylene 7042, and 4 parts of compatibilizer Taipol 7131 , 15 parts of JSL-PNA, 15 parts of FR-ADP02, 4 parts of triazine char-forming agent PPM Triazine HF, 10 parts of 32# white oil, 2 parts of erucamide, and 1 part of antioxidant 168.

[0059] First put SEBS elastomer and 32# white oil into the high-speed mixer in proportion, start stirring for 3 minutes, then add the remaining polyphenylene ether-polysiloxane copolymer, polypropylene 5090T, polyethylene 7042, compatibilizer Taipol 7131, compound halogen-free flame retardant, char forming agent, erucamide, and antioxidant 168 are put into a high-speed mixer in proportion, and the speed is 750...

Embodiment 3

[0061] The preparation method of this example halogen-free flame-retardant polyphenylene ether-polysiloxane thermoplastic elastomer is as follows:

[0062] Weigh 35 parts by mass of polyphenylene ether-polysiloxane copolymer with intrinsic viscosity of 0.35dL / g, 15 parts of SEBSYH502T, 15 parts of polypropylene 5090T, 4 parts of compatibilizer Taipol 7131, 15 parts of JSL-MC15 , 15 parts of FR-ADP02, 4 parts of triazine char-forming agent PPM Triazine HF, 10 parts of 32# white oil, 2 parts of oleic acid amide, and 1 part of antioxidant 1010.

[0063] First put SEBS elastomer and 32# white oil into the high-speed mixer in proportion, start stirring for 3 minutes, and then mix the remaining polyphenylene ether-polysiloxane copolymer, polypropylene 5090T, compatibilizer Taipol 7131, and compound without Halogenated flame retardant, char forming agent, oleic acid amide, and antioxidant 1010 are put into the high-speed mixer in proportion, and the speed is 750r / min, and the premix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com