Surface treatment method of implants

A surface treatment and implant technology, applied in the field of denture manufacturing, can solve the problems of uneven holes, great harm to human body and environment, and inexhaustible removal of white corundum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

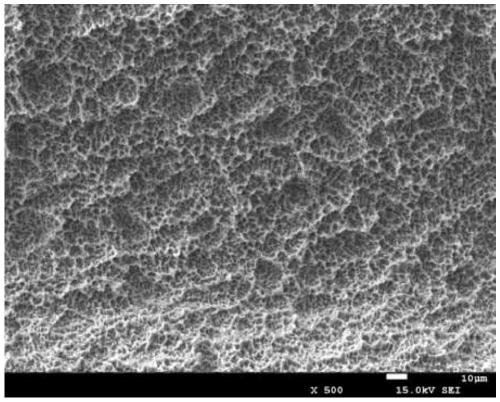

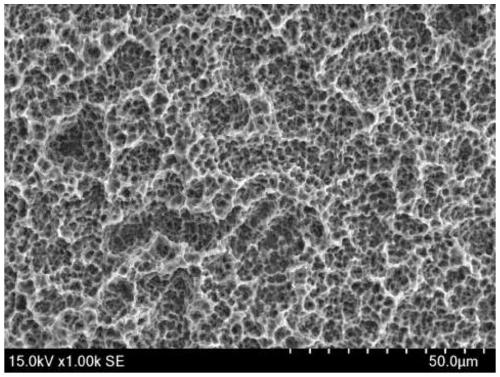

[0041] Example 1: Only use sandblasting + acid etching surface treatment

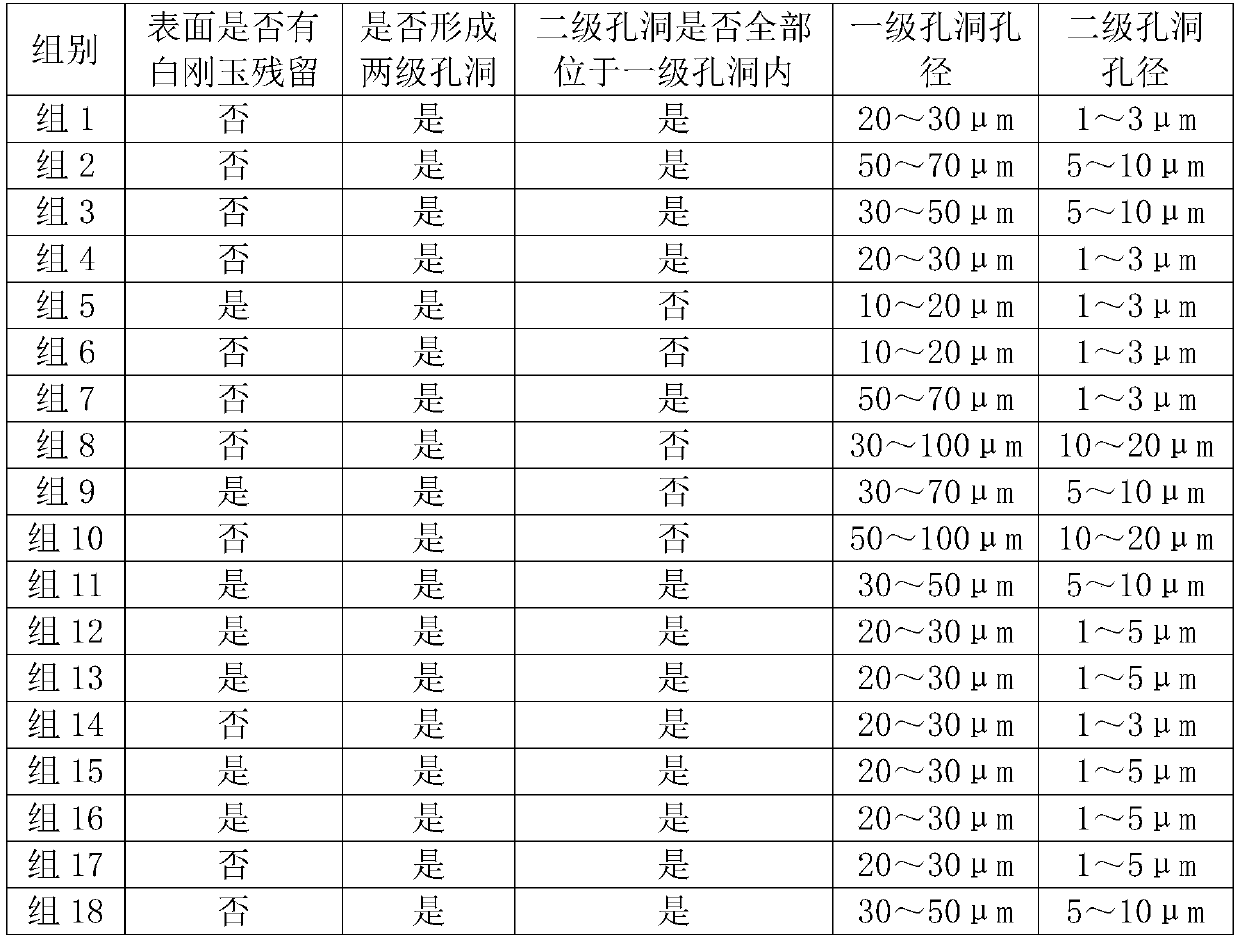

[0042] 1. The material of the implant used in this example is medical pure titanium, purchased from Suzhou Chuan Metallocene Materials Co., Ltd. The surface treatment of 18 groups of implants was carried out according to the method of step 1 above. Among them, the specific treatment methods of each group are shown in Table 1. Wherein, the balance of acid etching potion is water.

[0043] Table 1 Comparison table of treatment methods in each group

[0044] group Mesh of white corundum Sandblasting parameters Acid Potion Acid Etching Parameters group 1 150 mesh 0.3MPa, 60s, 4cm, 10° 35% sulfuric acid, 20% hydrochloric acid 75℃, 30min group 2 60 mesh 0.3MPa, 60s, 4cm, 10° 35% sulfuric acid, 20% hydrochloric acid 75℃, 30min group 3 100 mesh 0.3MPa, 60s, 4cm, 10° 35% sulfuric acid, 20% hydrochloric acid 75℃, 30min group 4 200 mesh 0.3MPa, 60...

Embodiment 2

[0048] Embodiment 2: after sandblasting+acid etching treatment, carry out MAO treatment

[0049] 1. Select the implants obtained in Group 1 of Example 1, and perform 10 groups of MAO treatments according to the method of Step 2 above. The treatment methods of each group are shown in Table 3.

[0050] Table 3 Comparison table of treatment methods in each group

[0051]

[0052]

[0053] 2. Taking the implants of Group 1 that were not carried out in Example 2 as the control group, the film thickness and stability of each group were measured. The method for measuring the stability of the film is: observe the surface of the implant with an electron microscope, and check whether the coating cracks or falls off.

[0054] Simultaneously biocompatibility testing was performed. The specific test method is as follows: the human osteosarcoma cell line MG63 was inoculated on the surface of the implants of each of the above groups, and each group was set up with 5 repetitions, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com