Method for artificially synthesizing large single crystal of columnar diamond

A kind of artificial synthesis and diamond technology, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc. It can solve the problems of difficult to meet, difficult to process diamond materials, and increased difficulty in utilization, and achieve low cost and high crystal quality. Excellent effect of reducing application difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

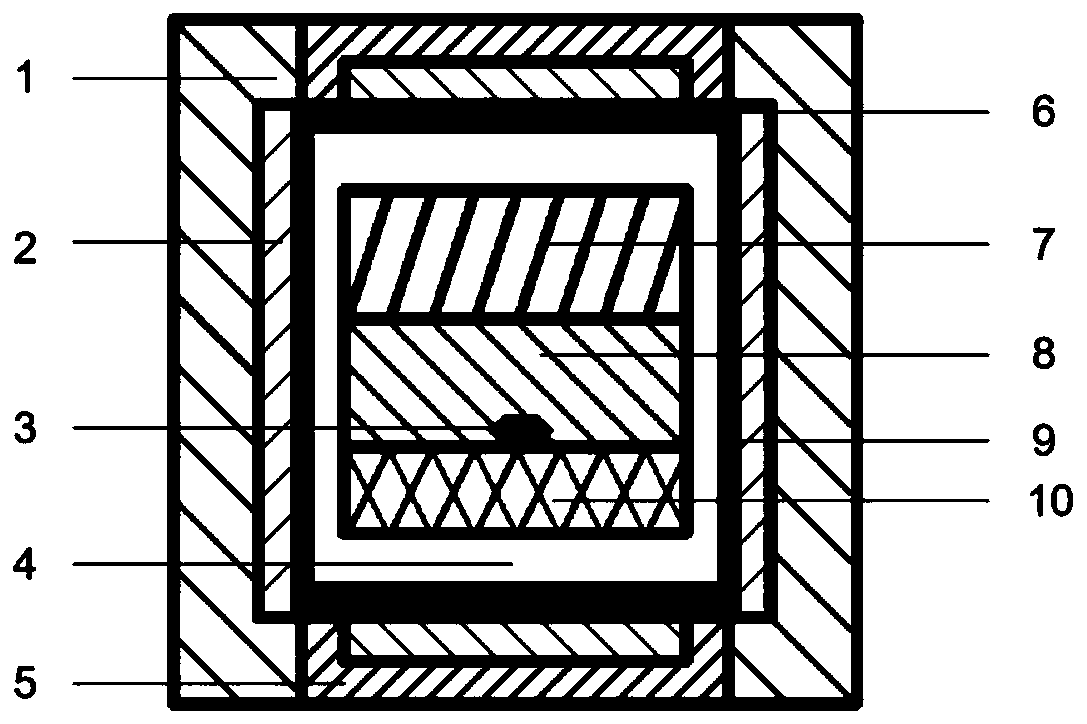

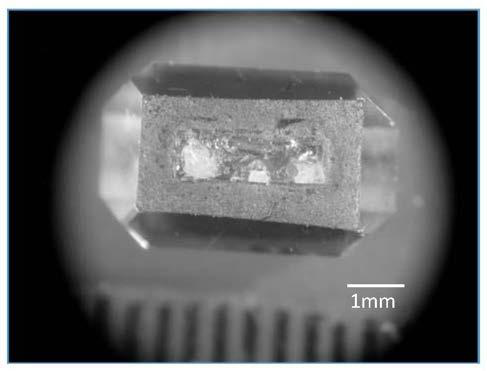

[0028] Embodiment 1 artificially synthesized columnar diamond plate crystal

[0029] Under the condition of temperature of 1280-1300℃, the synthesis was carried out for 24 hours by using {100} seed crystals with a length of 2.6 mm and a width of 0.8 mm. The shape of the large diamond single crystal synthesized under this condition is a columnar shape with a length of 5.0 mm, a width of 3.1 mm and a height of 2.0 mm, with good symmetry. The optical microscope photo of the synthesized large diamond single crystal is shown in figure 2 .

Embodiment 2

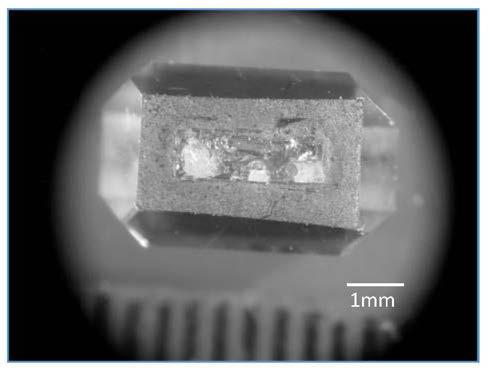

[0030] Embodiment 2 artificially synthesized columnar diamond lamellae

[0031] At a temperature of 1280-1300°C, a seed crystal with a length of 2.5 mm and a width of 0.5 mm was used for 12 hours of synthesis. Under this condition, the shape of the synthesized diamond large single crystal is 4.3 mm in length and 2.5 mm in width. A columnar shape with a height of 1.7 mm and good symmetry. The optical microscope photo of the synthesized large diamond single crystal is shown in image 3 .

Embodiment 3

[0032] Embodiment 3 artificially synthesized columnar diamond lamellae

[0033] Under the condition of a temperature of 1280-1300° C., a seed crystal with a length of 2.0 mm and a width of 0.5 mm was used for 29 hours of synthesis. The shape of the large diamond single crystal synthesized under this condition is a columnar diamond large single crystal with a length of 3.2 mm, a width of 1.7 mm, and a height of 1.0 mm. The optical microscope photo of the synthesized large diamond single crystal is shown in Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com