Ionic flexible touch sensor

A flexible touch and sensor technology, used in instruments, chemical instruments and methods, and input/output processes of data processing, etc., can solve the problems of complex manufacturing processes, limitations of flexible realization, and difficulty in ensuring uniformity, and achieves high raw material and Inexpensive, achieve the effect of contact detection, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

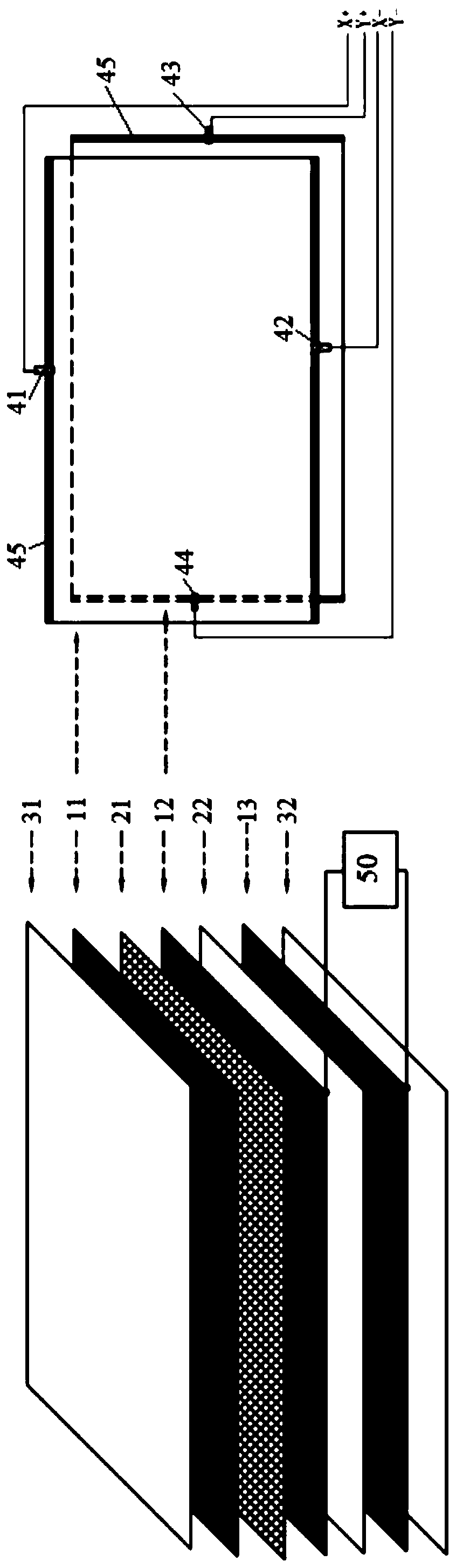

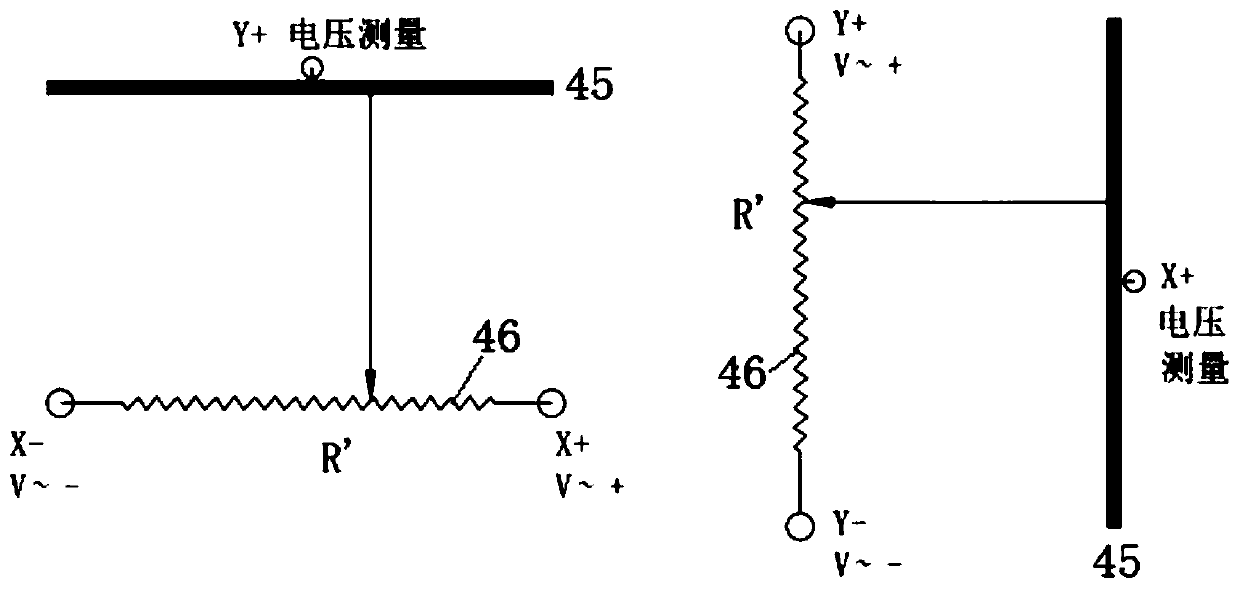

[0033] The present invention will be described in further detail below in combination with specific embodiments and with reference to the accompanying drawings. Wherein the same reference numerals denote the same components, unless otherwise specified. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0034] The present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings, so as to better understand the present invention, but the following embodiments do not limit the scope of the present invention. In addition, it should be noted that the diagrams provided in the following embodiments are only schematically illustrating the basic concept of the present invention, and only the components related to the present invention are shown in the drawings rather than the number of components, Shape and size drawing, the sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com