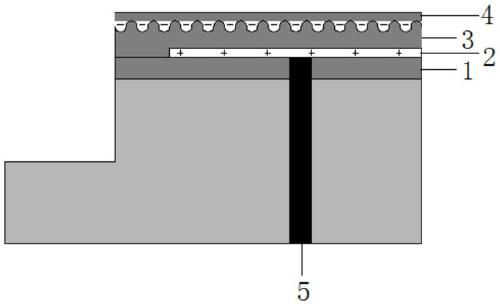

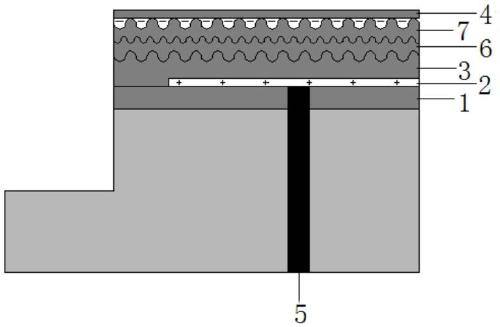

Structure for preventing back scrapping of electrode surface glass substrate under dry etching and process method of structure

A glass substrate, electrode surface technology, applied in the direction of metal material coating process, circuit, discharge tube, etc., can solve the problems of glass scratches, pits, product scrap, etc., and achieve the effect of preventing scratches and pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A process for preventing back scratching of a glass substrate on the surface of an electrode by dry engraving, the specific steps are as follows:

[0041] Step 1. Cleaning and drying: Use high-pressure water washing to clean the lower electrode. The resistivity of deionized water used in high-pressure water washing is greater than 4MΩ*cm, and the pressure is 100bar. Then use compressed air holes to dry the surface of the lower electrode, and finally dry it in an oven at 60°C 24h.

[0042] Step 2. Plasma spraying dense layer: plasma spraying is Y 2 o 3 and Al 2 o 3 The composite powder, where Y 2 o 3 The content is 80% (wt.). During plasma spraying, a six-axis manipulator is used to control the movement of the spray gun. The spraying process parameters are: the main gas Ar flow rate is 40L / min, the secondary gas H 2 The flow rate is 10L / min, the voltage is 36V, the current is 800A, the powder feeding rate is 10g / min, the spraying distance is 100mm, the thickness of...

Embodiment 2

[0048] A process for preventing back scratching of a glass substrate on the surface of an electrode by dry engraving, the specific steps are as follows:

[0049] Step 1. Cleaning and drying: Use high-pressure water washing to clean the lower electrode. The resistivity of deionized water used in high-pressure water washing is greater than 4MΩ*cm, and the pressure is 150bar. Then use compressed air holes to dry the surface of the lower electrode, and finally dry it in an oven at 80°C 12h.

[0050] Step 2. Plasma spraying dense layer: plasma spraying is Y 2 o 3 and Al 2 o 3 The composite powder, where Y 2 o 3 The content is 85% (wt.), and the six-axis manipulator is used to control the movement of the spray gun during plasma spraying. The spraying process parameters are: the main gas Ar flow rate is 60L / min, the secondary gas H 2 The flow rate is 15L / min, the voltage is 40V, the current is 900A, the powder feeding rate is 18g / min, the spraying distance is 150mm, the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com