Manufacturing process of diode chip with lateral electrode and shallow trench

A manufacturing process and diode technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as affecting the reliability and service life of devices, increasing the complexity of the circuit connection process, and being unfavorable for product miniaturization. Wide range of process applications, improved heat dissipation performance, and reduced material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

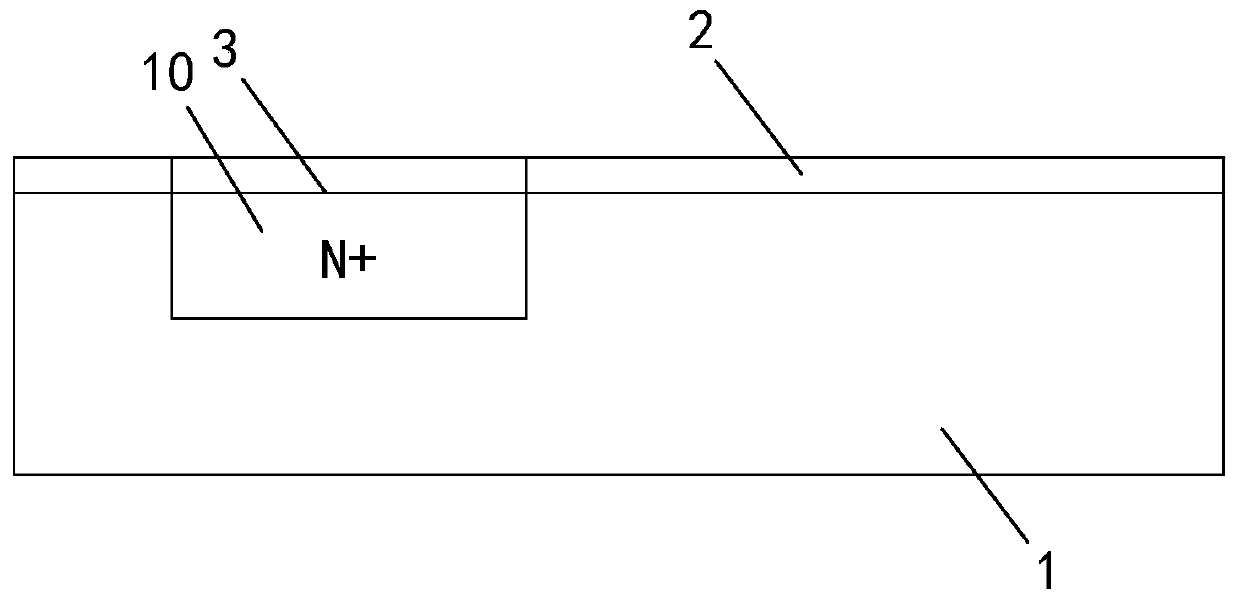

[0074] Example: see attached Figure 1~11 As shown, a manufacturing process of a diode chip with electrodes on the same side of a shallow trench; first, a silicon substrate 1 is selected, and the silicon substrate 1 can be selected from an N-type crystal orientation or a P-type crystal orientation, This embodiment takes the N-type crystal orientation as an example for illustration, and then proceeds according to the following steps:

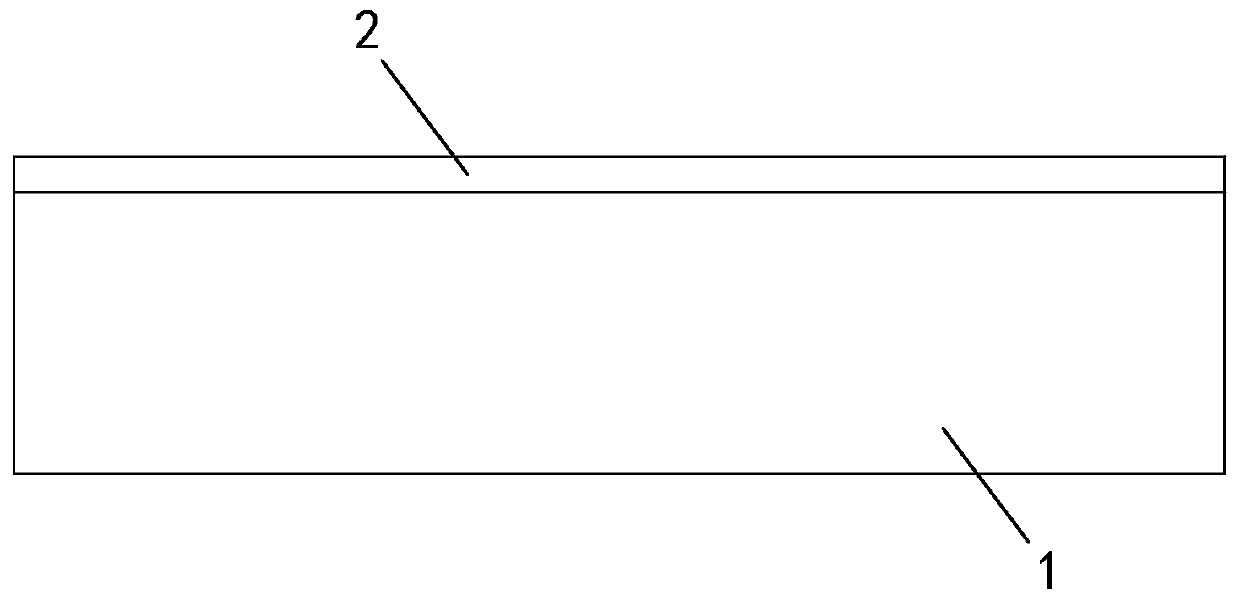

[0075] first step, such as figure 1 As shown, a layer of first silicon dioxide thin film layer 2 is formed on the upper surface of the silicon wafer substrate 1; the process conditions for the formation of the first silicon dioxide thin film layer 2 are: 1150 ± 0.5 ° C furnace tube, first through 30±5 minutes of oxygen (O 2 ) atmosphere, and then after 480±10 minutes of water vapor (H 2 O) atmosphere, and finally oxygen (O 2 )atmosphere.

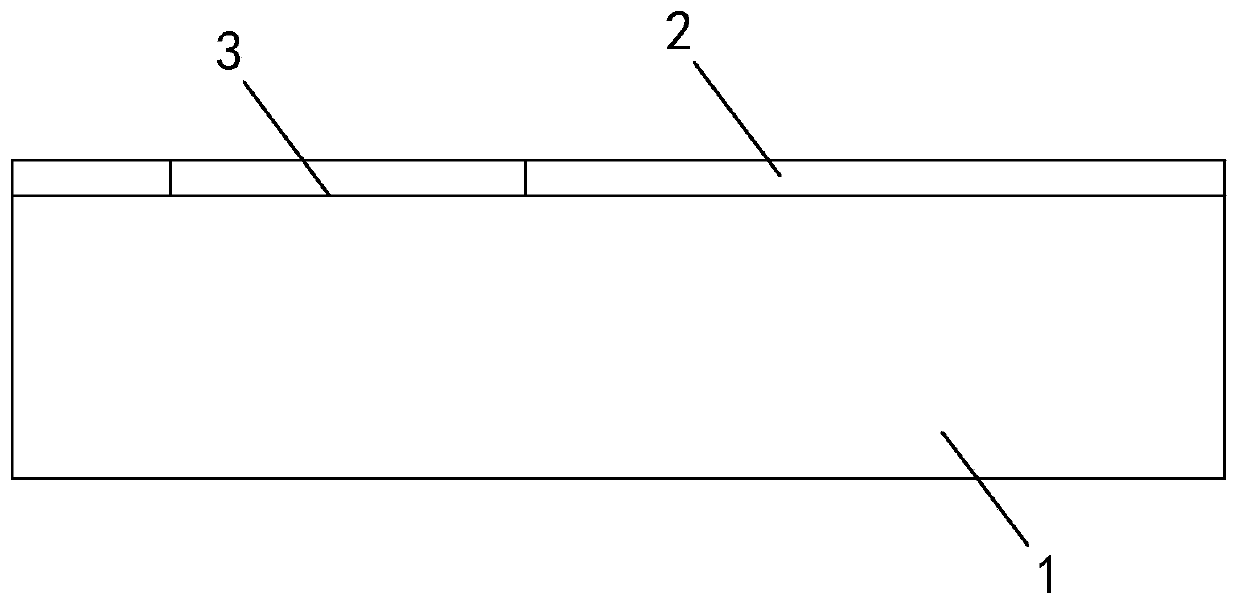

[0076] The second step, such as figure 2 As shown, the peripheral area of the first silicon diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com