Milk-ripe stage oat and wholemeal composite sesame protein peptide product and preparation method thereof

A technology of sesame protein peptide and milk-ripening stage, which is applied in the field of oat whole-wheat compound sesame protein-peptide product and preparation field at milk-ripening stage, can solve the problems of waste, low protein utilization rate and the like, and achieves inhibiting the growth of pathogenic bacteria and inhibiting the Pigmentation, the effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

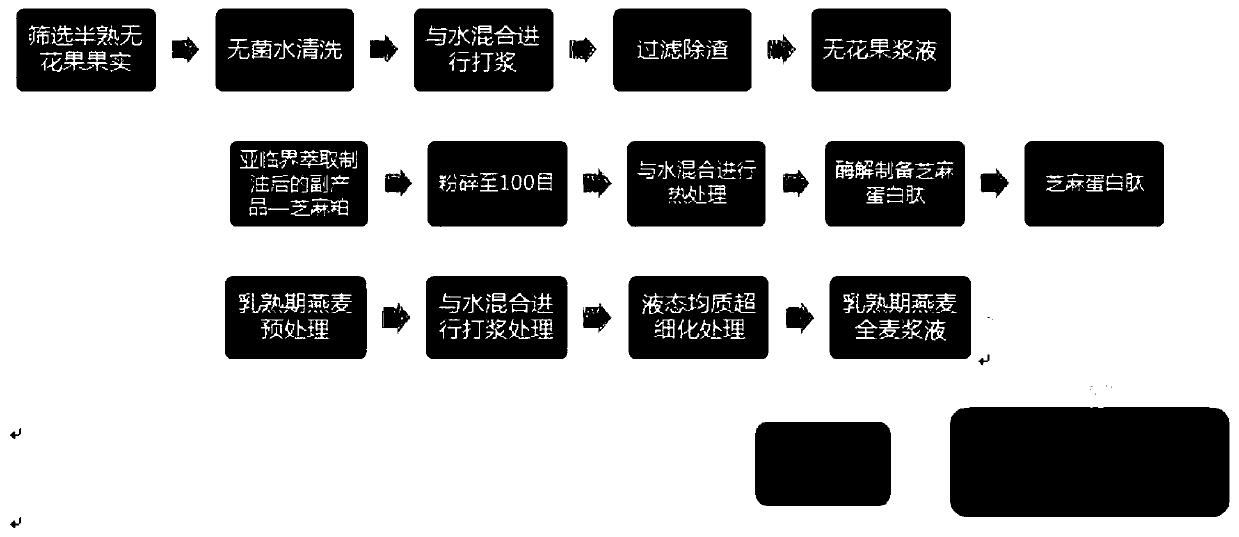

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing oat whole wheat compound sesame protein peptide product in milk ripening stage, the steps are as follows:

[0029] (1) prepare fig slurry

[0030] Select five-ripe, non-damaged fig fruits, wash them with sterile water, cut them into pieces, mix them with water at a mass ratio of 1:0.8, place them in a beater for beating, filter to remove the filter residue, and filter the slurry for later use;

[0031] (2) Sesame meal pretreatment

[0032] The sesame meal obtained after subcritical extraction for oil production was crushed to 100 mesh.

[0033] (3) Heat treatment before enzymatic hydrolysis

[0034] Mix the sesame meal treated in step (2) with water at a mass ratio of 1:15, place it at 85° C. for 5 minutes, cool it to room temperature, and set it aside.

[0035] (4) Preparation of sesame protein peptide slurry by enzymatic hydrolysis

[0036] Add 1 / 3 of the volume of fig slurry to the heat-treated sesame meal slurry in step (3), adjust the pH ...

Embodiment 2

[0046] A method for preparing oat whole wheat compound sesame protein peptide product in milk ripening stage, the steps are as follows:

[0047] (1) prepare fig slurry

[0048] Select five-ripe, non-damaged fig fruits, wash them with sterile water, cut them into pieces, mix them with water at a mass ratio of 1:1, put them in a beater for beating, filter to remove filter residue, and filter the slurry for later use.

[0049] (2) Sesame meal pretreatment

[0050] The sesame meal obtained after subcritical extraction for oil production was crushed to 100 mesh.

[0051] (3) Heat treatment before enzymatic hydrolysis

[0052] Mix the sesame meal treated in step (2) with water at a mass ratio of 1:20, place it at 95° C. for 10 minutes, cool it to room temperature, and set it aside.

[0053] (4) Preparation of sesame protein peptide slurry by enzymatic hydrolysis

[0054] Add 1 / 3 of the volume of fig slurry to the heat-treated sesame meal slurry in step (3), adjust the pH to 5.0-...

Embodiment 3

[0066] A method for preparing oat whole wheat compound sesame protein peptide product in milk ripening stage, the steps are as follows:

[0067] (1) prepare fig slurry

[0068] Select five-ripe, undamaged fig fruits, wash them with sterile water, cut them into pieces, mix them with water at a mass ratio of 1:0.9, put them in a beater for beating, filter to remove filter residue, and filter the slurry for later use.

[0069] (2) Sesame meal pretreatment

[0070] The sesame meal obtained after subcritical extraction for oil production was crushed to 100 mesh.

[0071] (3) Heat treatment before enzymatic hydrolysis

[0072] The sesame meal treated in step (2) was mixed with water at a mass ratio of 1:19, placed at 90°C for 8 minutes, cooled to room temperature, and set aside.

[0073] (4) Preparation of sesame protein peptide slurry by enzymatic hydrolysis

[0074] Add 1 / 3 of the volume of fig slurry to the heat-treated sesame meal slurry in step (3), adjust the pH to 5.0-5.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com