Preparation method of BiPO4 nano photocatalyst

A nano-photocatalyst, mixed solution technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor adsorption performance, low dispersion, easy agglomeration, etc., to improve photochemical performance , good particle dispersibility and interface properties, the effect of improving monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

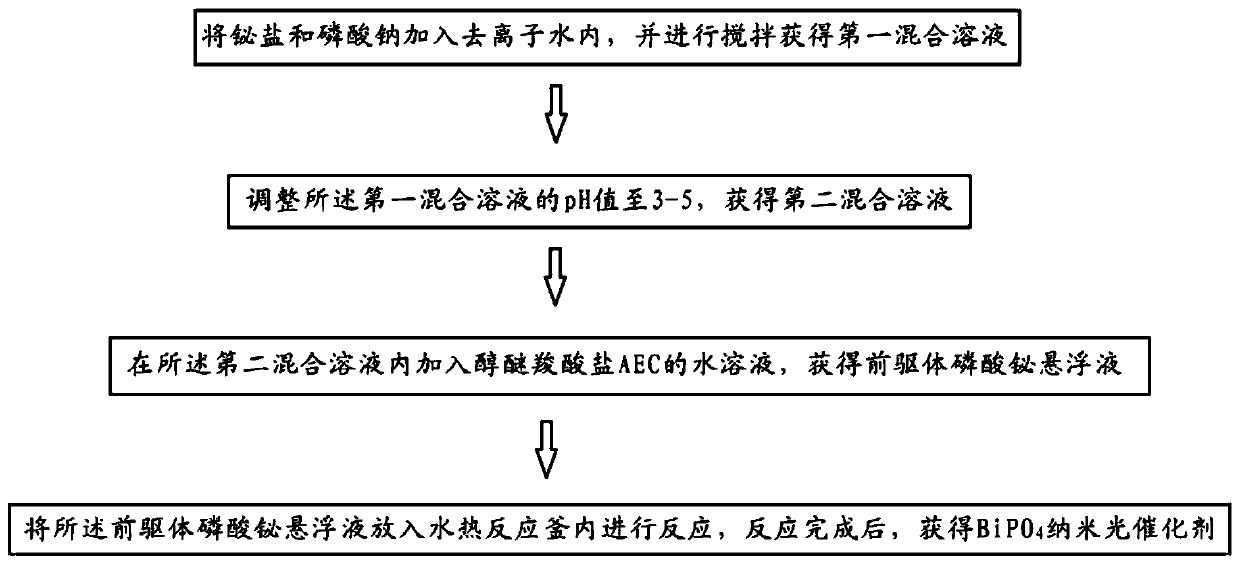

[0021] see figure 1 , a kind of BiPO provided by the embodiment of the present invention 4 The preparation method of nano photocatalyst comprises the following steps:

[0022] Step S1, adding bismuth salt and sodium phosphate into deionized water, and stirring to obtain a first mixed solution.

[0023] Step S2, adjusting the pH value of the first mixed solution to 3-5 to obtain a second mixed solution.

[0024] Step S3, adding an aqueous solution of alcohol ether carboxylate AEC to the second mixed solution to obtain a precursor bismuth phosphate suspension.

[0025] Step S4, put the precursor bismuth phosphate suspension into the hydrothermal reactor for reaction, after the reaction is completed, BiPO 4 Nanophotocatalyst.

[0026] Specific embodiments of the present application Since the bismuth salt and sodium phosphate are added into the deionized water and stirred to obtain the first mixed solution, the pH value of the first mixed solution is adjusted to 3-5 to obtain ...

Embodiment 1

[0044] Add 0.8g of bismuth salt (bismuth sulfate) and 1.2g of sodium phosphate into the beaker, then add 200ml of deionized water, and magnetically stir at room temperature. During this period, the pH value of the solution was adjusted to 3 by adding nitric acid or sodium hydroxide, and then 1 g of an aqueous solution of alcohol ether carboxylate AEC was added. The final concentration of alcohol ether carboxylate AEC was 25 g / L to obtain a precursor bismuth phosphate suspension.

[0045] Subsequently, 100 ml of the precursor bismuth phosphate suspension was put into a 200 ml Teflon hydrothermal reaction kettle, and reacted at 160° C. for 36 hours. Then take it out and cool to room temperature under natural conditions to obtain BiPO 4 Nanophotocatalyst.

[0046] BiPO 4 The nano-photocatalyst was washed several times with deionized water, and dried in a vacuum drying oven at 60°C for 24 hours to obtain BiPO 4 Nano photocatalyst powder. Obtained BiPO 4 Nano photocatalyst pow...

Embodiment 2

[0050] 0.8 g of bismuth salt (bismuth nitrate) and 1.2 g of sodium phosphate were added to the beaker, followed by 150 ml of deionized water, and magnetically stirred at room temperature. During this period, the pH value of the solution was adjusted to 5 by adding nitric acid or sodium hydroxide, and then 0.25 g of an aqueous solution of alcohol ether carboxylate AEC was added, and its final concentration was 5 g / L.

[0051] Subsequently, 100 ml of the precursor bismuth phosphate suspension was put into a 200 ml Teflon hydrothermal reaction kettle, and reacted at 180° C. for 42 hours. Then take it out and let it cool down to room temperature naturally. The material was then washed several times with deionized water, and dried in a vacuum drying oven at 60 °C for 24 hours to obtain BiPO 4 Nano photocatalyst powder. Obtained BiPO 4 Nanophotocatalyst powder compared with BiPO not modified with alcohol ether carboxylate AEC 4 Powder, with high specific surface area and good ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com