Baffling type ammonia-nitrogen wastewater advanced denitrification device and method

A technology of ammonia nitrogen wastewater and deep denitrification, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc. problem, to achieve the effect of enhancing the production efficiency of effective chlorine, the efficient denitrification reaction, and the prevention of short-circuit current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

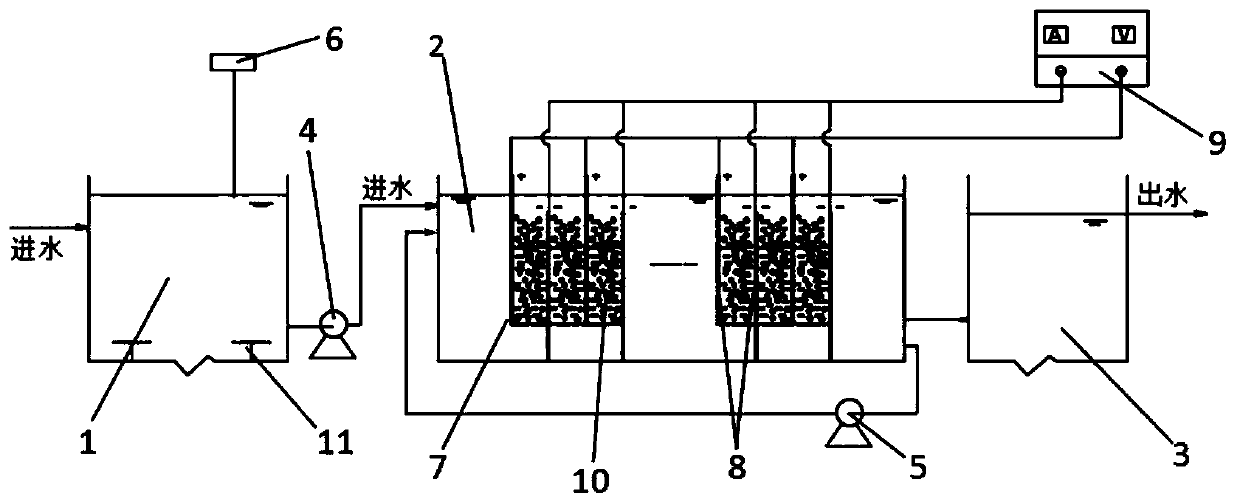

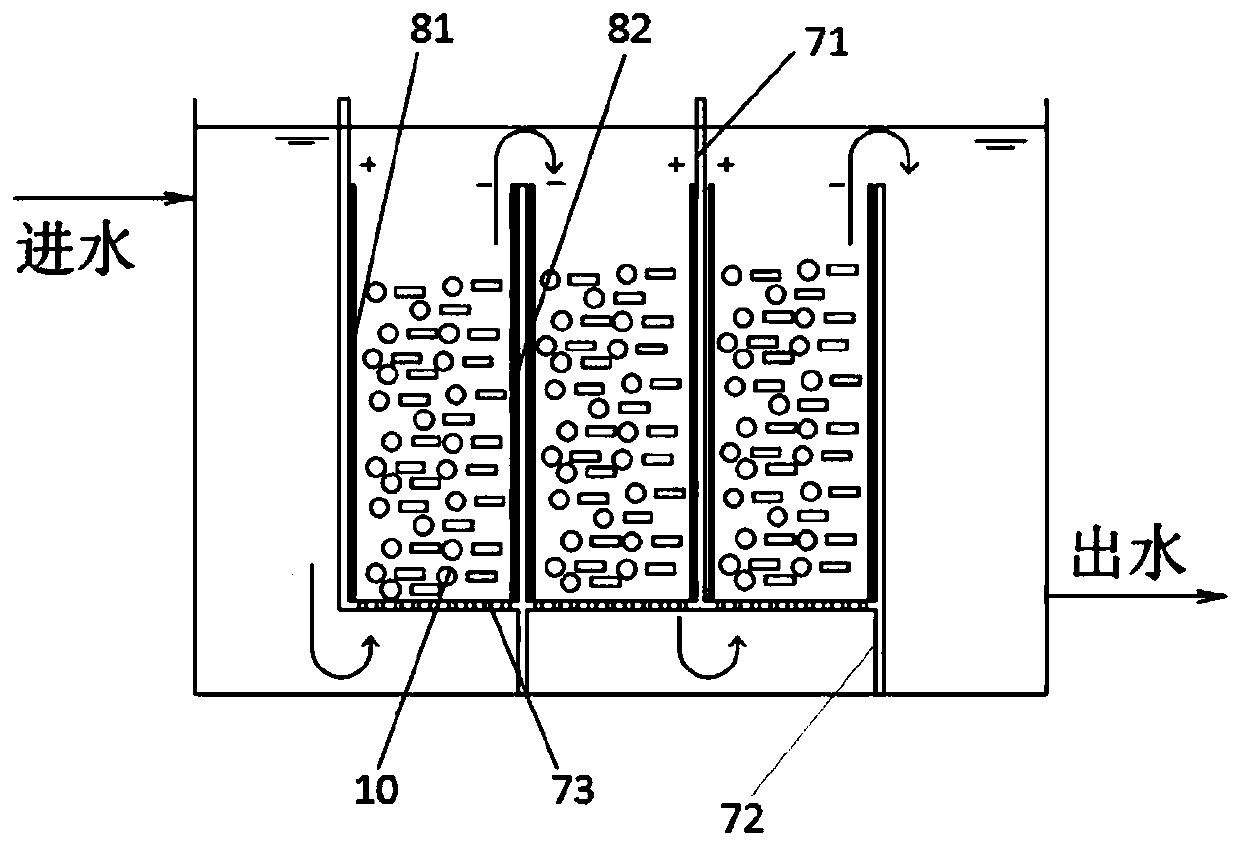

Method used

Image

Examples

Embodiment 1

[0039] The wastewater used is the effluent of high ammonia nitrogen wastewater from a pig farm treated by traditional biochemical process, as shown in Table 1, the ammonia nitrogen content of the wastewater is 170mg / L, the chloride ion content is low, and pH=7.2.

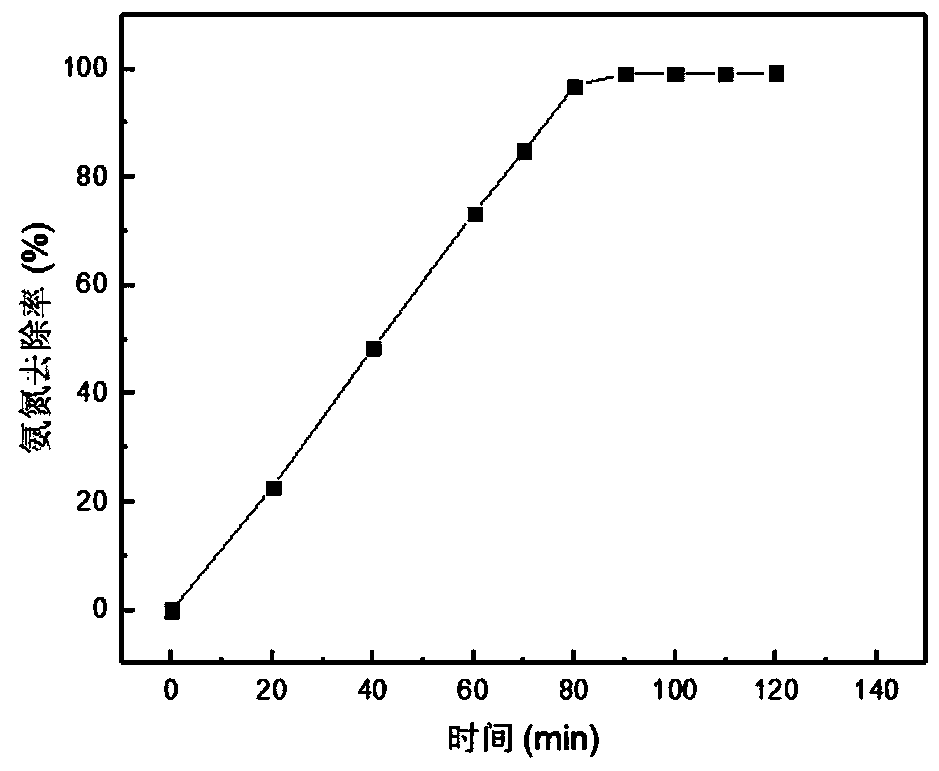

[0040] Use an electrochlorination device to denitrify it. The plate of the electrolysis reactor is a single-stage structure. Columnar activated carbon and glass particles are mixed as three-dimensional particle fillers. The electrolysis voltage U=25v, and the current density of the positive and negative plates is 35mA / cm 2 , add sodium chloride, and adjust the molar ratio of ammonia nitrogen to chloride ions to be 1:28. During the electrolysis process, the concentration of ammonia nitrogen in the wastewater changes as image 3 Shown, when reacting 80min, the removal rate of ammonia nitrogen is as high as 98%.

[0041] Table 1 Indicators of wastewater to be treated

[0042] Element Ammonia nitrogen Cl ...

Embodiment 2

[0044] Adopt the waste water and device among the embodiment 1, set the current density of positive and negative plates to be 20mA / cm 2 , and add sodium chloride to adjust the molar ratio of ammonia nitrogen to chloride ions to be 1:22. Other reaction conditions are the same. The experimental results show that the removal rate of ammonia nitrogen reaches 98% in 90 minutes.

Embodiment 3

[0046] Adopt the waste water and device among the embodiment 1, set the current density of positive and negative plates to be 50mA / cm 2 , and add sodium chloride to adjust the molar ratio of ammonia nitrogen to chloride ions to be 1:33. Other reaction conditions are the same. The experimental results show that the removal rate of ammonia nitrogen can reach 99% in 70 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com