A kind of modified graphene oxide, its application, the wire drawing liquid containing it and preparation method

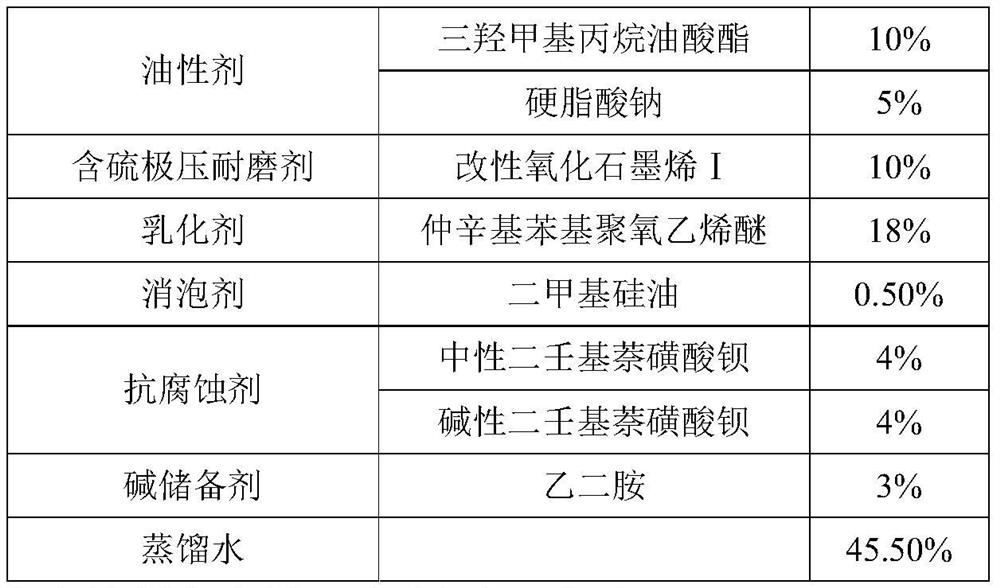

A technology of oxidized stone and wire drawing fluid, which is applied in chemical instruments and methods, petroleum industry, dyeing organic silicon compound treatment, etc., can solve the problems of poor corrosion resistance, poor extreme pressure wear resistance, etc., achieve good lubrication performance and improve corrosion resistance The effect of ensuring the smoothness of the metal surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

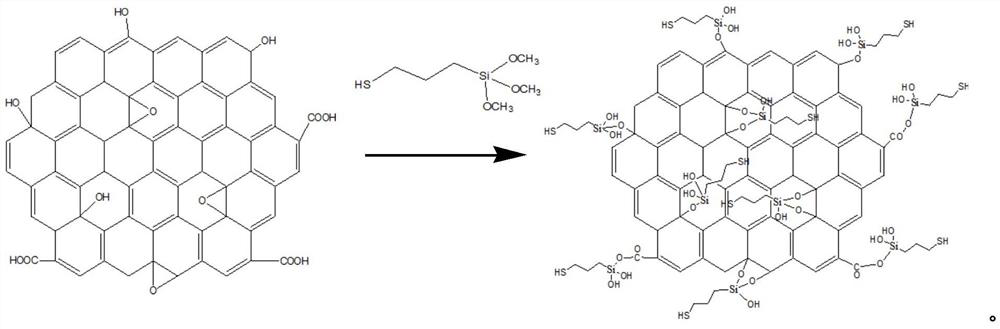

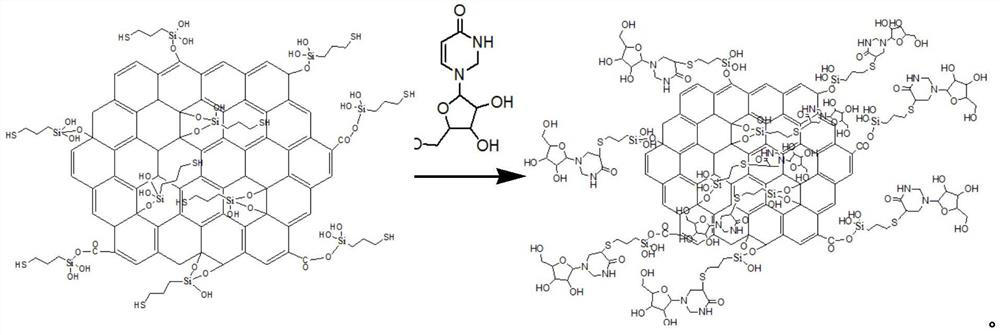

[0030] A modified graphene oxide, prepared from γ-mercaptopropylmethyldimethoxysilane, graphene oxide and uridine, the graphene oxide is a single layer with a sheet diameter of 0.5-1.0 μm Nano-graphene oxide, with a purity of 98%, a thickness of 0.335nm, a carbon content of 40%, an oxygen content of 58%, and a sulfur content of 0.5%. The preparation process is as follows:

[0031] (1) Under nitrogen protection, γ-mercaptopropylmethyldimethoxysilane and graphene oxide with a mass ratio of 10:1 are added to a mixed solvent with a volume ratio of water and ethanol of 1:1, and hydrochloric acid is adjusted pH to 3, heated to 80°C, dehydration condensation reaction between the hydrolyzed γ-mercaptopropylmethyldimethoxysilane and graphene oxide, after 10 hours of reaction, washing with ethanol to obtain an intermediate product with a mercapto group;

[0032] (2) Under the protection of nitrogen, the intermediate product and uridine with a mass ratio of 1:1 are added to ethanol and w...

Embodiment 2

[0034] A modified graphene oxide, made from γ-mercaptopropyl trimethoxy silicon, graphene oxide and uridine, the graphene oxide is a single-layer nano-graphene oxide with a sheet diameter of 3-5 μm , with a purity of 96%, a thickness of 1.0nm, a carbon content of 35%, an oxygen content of 65%, and a sulfur content of 0.8%. The preparation process is as follows:

[0035] (1) Under nitrogen protection, γ-mercaptopropyl trimethoxy silicon and graphene oxide with a mass ratio of 5:1 are added to a mixed solvent with a volume ratio of water and ethanol of 2:1, and the pH is adjusted to 4 with hydrochloric acid. , heated to 85°C, the hydrolyzed γ-mercaptopropyl trimethoxy silicon and graphene oxide undergo a dehydration condensation reaction, and after reacting for 9 hours, wash with ethanol to obtain an intermediate product with a mercapto group;

[0036] (2) Under the protection of nitrogen, the intermediate product and uridine with a mass ratio of 1:2 are added to ethanol and wat...

Embodiment 3

[0038] A modified graphene oxide, made from γ-mercaptopropylmethyldimethoxysilane, graphene oxide and uridine, the graphene oxide is a single-sheet nanometer with a sheet diameter of 1-3 μm Graphene oxide has a purity of 97%, a thickness of 0.5nm, a carbon content of 45%, an oxygen content of 55%, and a sulfur content of 0.6%. The preparation process is as follows:

[0039] (1) Under nitrogen protection, γ-mercaptopropylmethyldimethoxysilane and graphene oxide with a mass ratio of 8:1 are added to a mixed solvent with a volume ratio of water and ethanol of 5:1, and hydrochloric acid is adjusted pH to 5, heated to 80°C, dehydration condensation reaction between the hydrolyzed γ-mercaptopropylmethyldimethoxysilane and graphene oxide, after 12 hours of reaction, washing with ethanol to obtain an intermediate product with a mercapto group;

[0040] (2) Under the protection of nitrogen, the intermediate product and uridine with a mass ratio of 1:1.5 are added to ethanol and water wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com