Stripping method of SiC-based GaN epitaxial wafer

A technology of epitaxial wafers and oxygen ions, which is applied in the field of semiconductors, can solve the problems of low stacking fault formation energy, SiC substrate waste, and increased difficulty, and achieve the effects of easy subsequent stripping, increased utilization rate, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

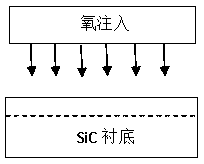

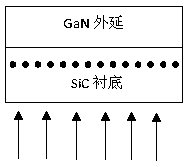

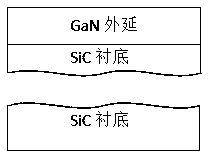

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Disclosed in the present invention is a method for stripping off a SiC-based GaN epitaxial wafer, such as figure 1 , figure 2 and image 3 As shown, it specifically includes the following steps: Step S1: By implanting oxygen ions, an oxygen layer and a SiO layer are formed under the surface of the SiC substrate. 2 , at the same time, react to form a bubble layer; step S2: generate GaN epitaxy on the surface layer of the substrate; step S3: perform laser cutting along the bubble layer to obtain SiC-based GaN epitaxial wafers. The remaining SiC substrates can be recycled, thereby increasing the utilization rate of SiC substrates.

[0029] Further, in step S1, before implanting oxygen ions, a silicon nitride dielectric layer is deposited on the SiC substrate to protect the interface of the SiC substrate. The thickness of the dielectri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com