A method of splicing and growing large-scale single crystal diamond epitaxial wafers

A single crystal diamond and growth method technology, applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the difficulty of preparing single crystal diamond wafers for diamond semiconductor devices, the technical complexity, and the preparation of large-size single crystal diamond materials. The problem has not been well solved, etc., to achieve the effect of low cracking and breaking probability, increasing size limit, and small residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

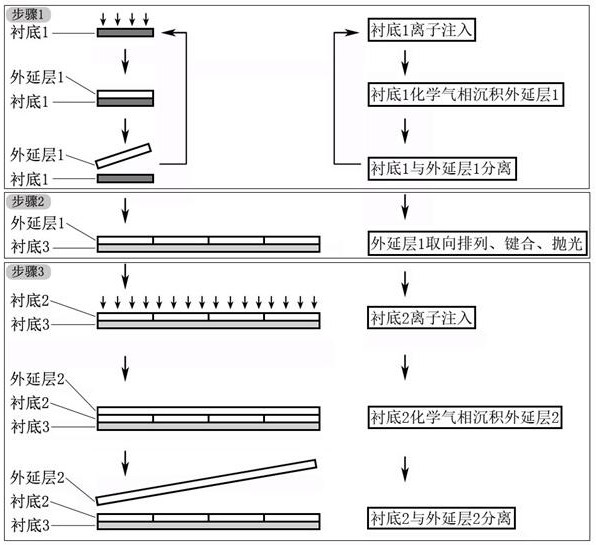

[0030] The specific preparation process of the present invention is as figure 1 As shown, firstly, the chemical vapor deposition method is selected to synthesize macro-defect-free, and the dislocation density is lower than 5000 / cm 2 The single crystal diamond is used as the substrate 1, the substrate 1 is cut and polished, the direction error between the cutting surface and the (100) crystal plane does not exceed ±1°, and the cutting size is 7×7mm 2 , Flaky square crystals with a thickness of 0.5mm. Grinding and polishing the cut substrate 1, the roughness of the upper and lower main surfaces of the crystal after polishing is not more than 5nm, and the roughness of the four sides is not more than 100nm.

[0031] Impl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com