Kitchen garbage composting device

A kitchen waste and composting technology, applied in the fields of organic fertilizer, climate change adaptation, biological organic part treatment, etc., can solve the problems affecting the biodegradation speed and degree of degradation, the reduction of microbial activity, water loss, etc., to promote electrical conductivity, sustainable Buffer salt and absorb water to ensure active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the embodiments of the present invention will be described in detail with reference to the accompanying drawings and embodiments, so as to understand the technical content of the present invention more clearly.

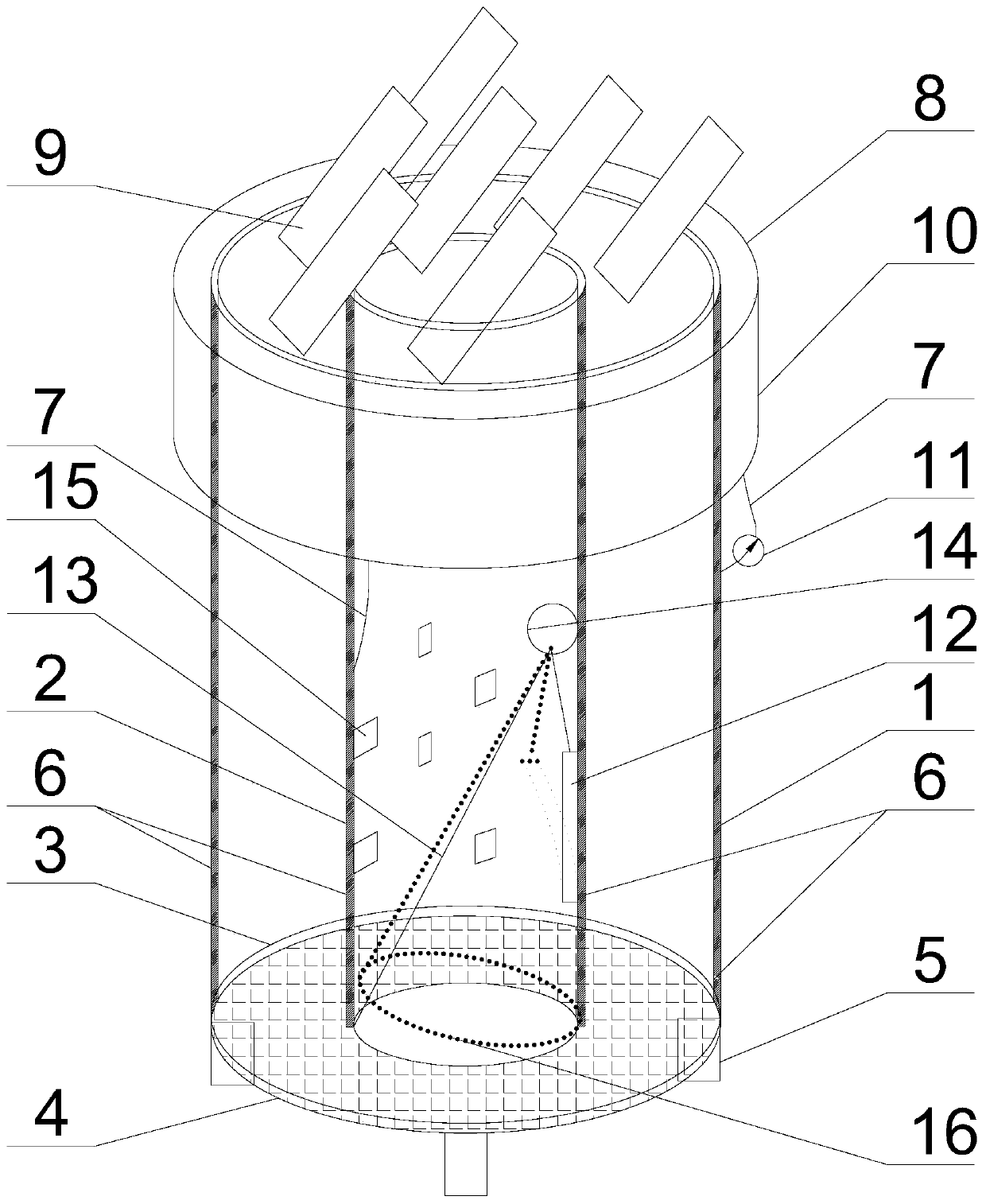

[0030] Such as figure 1 As shown, in a specific embodiment of the present invention, a kitchen waste composting device includes in order: a top, a main body and a bottom, wherein,

[0031] The main body includes an outer cylinder 1 and an inner cylinder 2 coaxially arranged inside the outer cylinder 1. The outer cylinder 1 and the inner cylinder 2 are two stainless steel hollow cylinders of equal height, and the bottoms of the outer cylinder 1 and the inner cylinder 2 are on the same level. The inner wall of the outer cylinder 1 and the outer wall of the inner cylinder 2 are each provided with a filler layer 6, the filler in the filler layer 6 is composed of calcium bentonite, activated carbon powder and calcium carbonate, the inner wall of the inner cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com