Tandem synthesis method of 2-(phenylmethylene)malononitrile or derivative thereof

A technology of phenylmethylene and synthesis methods, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid nitrile, etc., can solve the problems of long reaction time, low yield, complicated separation of catalysts and products, etc., To achieve the effect of short reaction time, high reaction activity and cheap catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

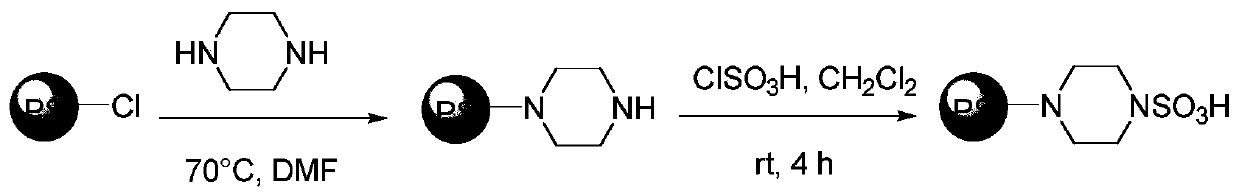

Method used

Image

Examples

Embodiment 1

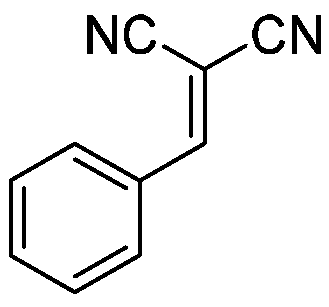

[0030] The preparation of 2-(phenylmethylene) malononitrile (structural formula is as follows):

[0031]

[0032] The mixture of 3.3mmol benzaldehyde dimethyl acetal and 3.8mmol malononitrile was diluted to 10mL with ethyl acetate, and then the resulting solution was injected into the HPLC column at a flow rate of 0.5mL / min (PS-piperazine 0.8-1.0g and PS-piperazine-1-sulfonic acid 0.8-1.0 g), while immersing the HPLC column in a 50°C oil bath. After the reaction was completed, the HPLC column was washed with ethyl acetate, the product was collected, the solvent was evaporated, and recrystallized with ethanol to obtain a solid product with a yield of 94%.

[0033] Compared with the traditional route for preparing the compound, the method has the advantages of cheap and easy-to-obtain catalyst, high reaction activity, short reaction time, the product can be obtained without intermediate separation, and the product yield is high. The melting point, IR and NMR characteristics ...

Embodiment 2

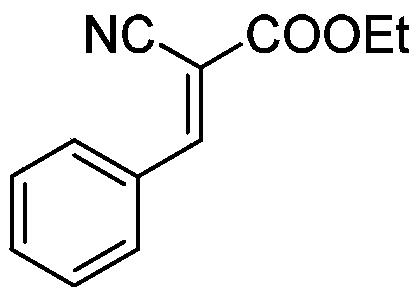

[0035] (E) the preparation of -2-cyano-3-ethyl phenylacrylate (structural formula is as follows):

[0036]

[0037] Mix 3.3 mmol benzaldehyde dimethyl acetal with 3.8 mmol nitrile ethyl acetate and dilute to 10 mL with ethyl acetate, then inject the resulting solution into an HPLC column (PS-piperazine 0.8 -1.0g and PS-piperazine-1-sulfonic acid 0.8-1.0g), while immersing the HPLC column in a 50°C oil bath. After the reaction was completed, the HPLC column was washed with ethyl acetate, the product was collected, the solvent was evaporated, and recrystallized with ethanol to obtain a solid product with a yield of 86%.

[0038] Compared with the traditional route for preparing the compound, the method has the advantages of cheap and easy-to-obtain catalyst, high reaction activity, short reaction time, the product can be obtained without intermediate separation, and the product yield is high. The melting point, IR and NMR characteristics of the compound are as follows: m.p.4...

Embodiment 3

[0040] The preparation of 2-(4-methoxyphenylmethylene) malononitrile (structural formula is as follows):

[0041]

[0042] The mixture of 3.3mmol p-methoxybenzaldehyde dimethyl acetal and 3.8mmol malononitrile was diluted to 10mL with ethyl acetate, and then the resulting solution was injected into the HPLC column (PS-piperazine 0.8-1.0g and PS-piperazine-1-sulfonic acid 0.8-1.0g), while immersing the HPLC column in a 50°C oil bath. After the reaction was completed, the HPLC column was washed with ethyl acetate, the product was collected, the solvent was evaporated, and recrystallized with ethanol to obtain a solid product with a yield of 95%.

[0043] Compared with the traditional route for preparing the compound, the method has the advantages of cheap and easy-to-obtain catalyst, high reaction activity, short reaction time, the product can be obtained without intermediate separation, and the product yield is high. The melting point, infrared and NMR characteristics of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com