A method for preventing coking and sticking of cold-pressed iron

A technology of iron coke and cold pressing, which is applied in the field of iron and steel metallurgy, can solve the problems of cumbersome preparation and use of inhibitors, inapplicability of cold pressing iron coke, and increased production costs, so as to prevent carbonization and sticking, low price, and high efficiency. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

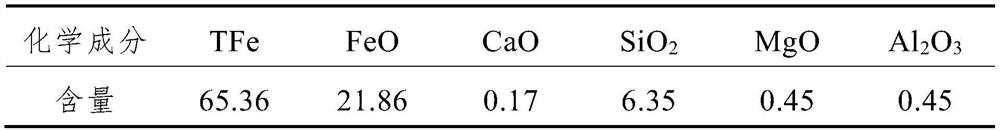

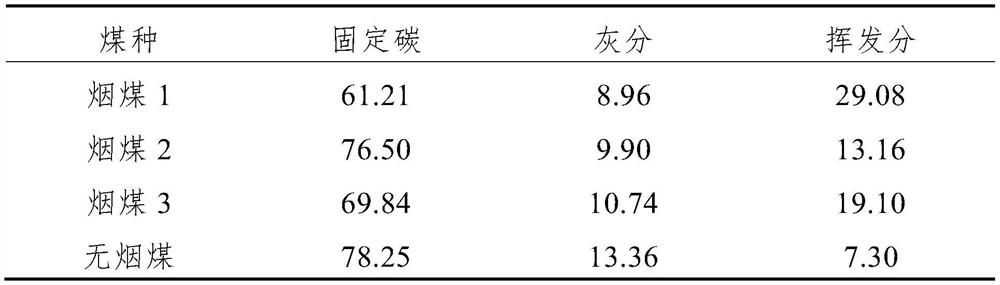

[0029] Step S1, preparation of the first iron coke green pellets: according to 10%-40% iron ore powder, 55%-80% bituminous coal and 5%-10% anthracite, uniformly mix iron ore powder, bituminous coal and anthracite, and heat to 60-150 °C to obtain the first mixture; spray 5% to 7% steam-heated asphalt binder into the first mixture and mix evenly to obtain the second mixture; at a pressure of 3t / cm to 6t / cm The second mixture is subjected to counter-roll cold pressing to obtain the first iron coke green pellets.

[0030] Bituminous coal and anthracite are non-coking coals. Using them as raw materials for making iron coke is not only cheap, but also greatly improves the source of raw materials and the comprehensive utilization of waste. Heating the uniformly mixed iron ore powder and coal powder ensures that the bitumen still has good fluidity when added to the first mixture, so as to promote the uniform mixing of the bitumen and the first mixture.

[0031] Step S2, preparation o...

Embodiment 1

[0053] Step S1, the preparation of the first iron coke green pellets is the same as that of Comparative Example 1.

[0054] Step S2, preparation of the second iron coke green ball: according to the spraying amount of the cement dispersion liquid being 5% of the mass of the first iron coke green ball, 13.5% of the commercially available cement dispersion liquid is sprayed on the first iron coke green ball by using compressed air with a pressure of 0.6-1.0 MPa. The surface of the iron burnt ball is obtained to obtain the second iron burnt ball.

[0055] Step S3, preparation of iron coke products: put the second iron coke green pellets into the shaft furnace, 2 Dry distillation is carried out under the mixed atmosphere of CO and CO to control CO 2 The partial pressure of the gas is below 10%, CO 2 The total gas flow rate of mixed gas with CO is 5L / min; the second iron coke green pellets are heated from room temperature to 550°C at a heating rate of 3°C / min in the shaft furnace,...

Embodiment 2

[0058] Step S1, the preparation of the first iron coke green pellets is the same as that of Comparative Example 1.

[0059] Step S2, preparation of the second iron coke green balls: according to the spraying amount of the cement dispersion liquid being 5% of the mass of the first iron coke green balls, 18% of the commercially available cement dispersion liquid is sprayed on the first iron coke green balls by using compressed air with a pressure of 0.6-1.0 MPa. The surface of the iron burnt ball is obtained to obtain the second iron burnt ball.

[0060] Step S3, preparation of iron coke products: put the second iron coke green pellets into the shaft furnace, 2 Dry distillation is carried out under the mixed atmosphere of CO and CO to control CO 2 The partial pressure of the gas is below 10%, CO 2 The total gas flow rate of mixed gas with CO is 5L / min; the second iron coke green pellets are heated from room temperature to 550°C at a heating rate of 3°C / min in the shaft furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com