High-fracture-toughness aluminum magnesium scandium alloy rod and preparation method thereof

A technology for alloy rods and high fracture, which is applied in the field of high fracture toughness aluminum-magnesium-scandium alloy rods and its preparation, and can solve the problems of reduced fracture toughness, need for improvement, and increased mismatch between the second phase and the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

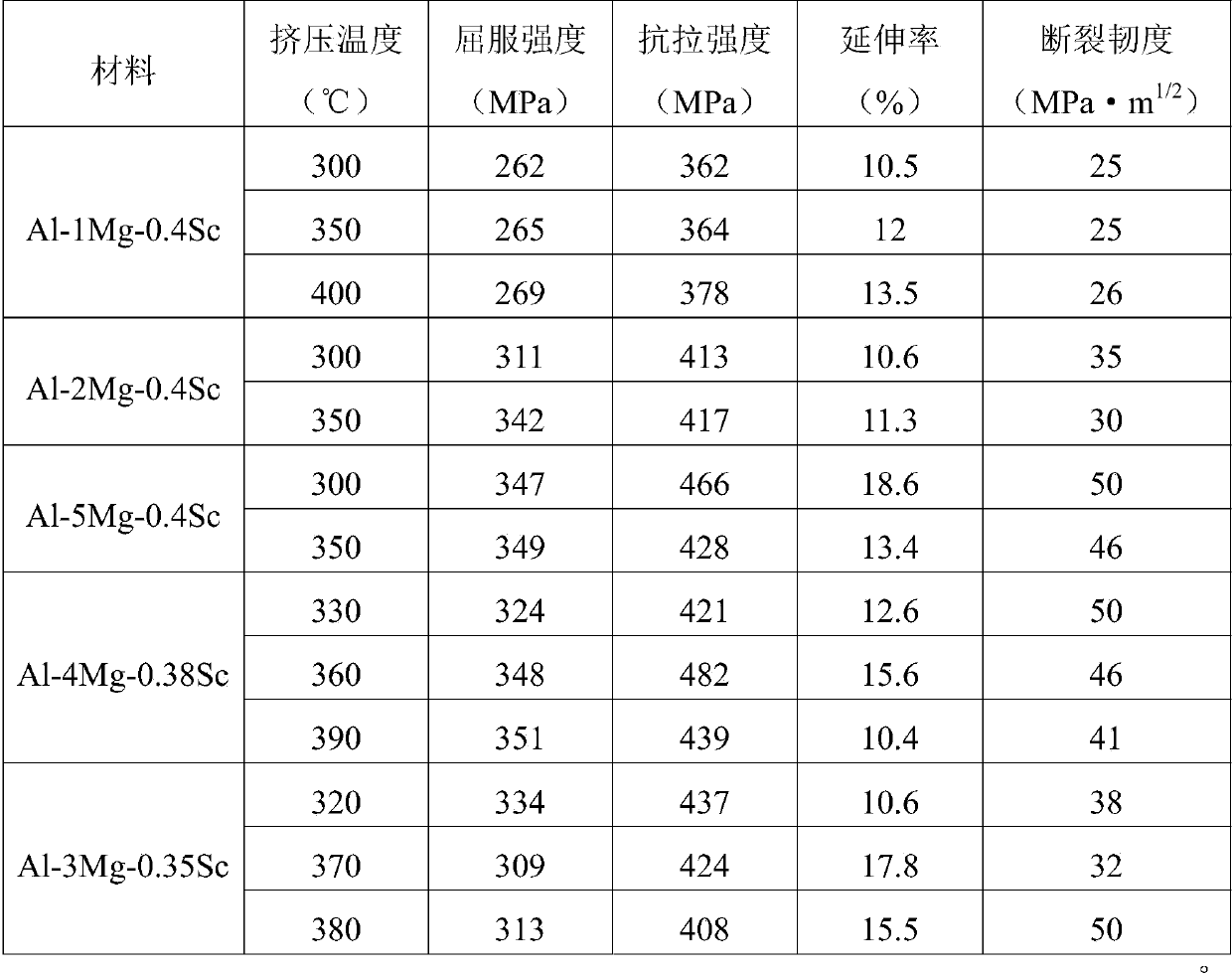

Embodiment 1

[0025] The constituent elements of the bar are: Mg 1wt%, Sc 0.4wt%, Al 98.6wt%, Fe, Si and other impurity elements content ≤ 0.1wt%.

[0026] According to the ratio, put the aluminum ingot with a purity ≥99.9% in a graphite crucible of an intermediate frequency induction melting furnace to melt it. After it is completely melted, the temperature of the molten aluminum is 660-670°C, and then add magnesium with a purity ≥99.9% to the molten aluminum. Ingot and Al-2%Sc master alloy, heat up to 730°C for full stirring after melting the alloy, refine and degas at 720°C after standing for 20 minutes, stand for 20 minutes after removing slag from the melt, and quickly pour the molten metal at 700°C Aluminum alloy casting ingot; brighten the surface of the ingot, preheat the ingot and carry out hot extrusion according to the extrusion ratio of 25, the extrusion temperature is 300, 350, 400°C, and the heat treatment program is 470°C-2h+120°C -16h+160°C-20min+120°C-16h to obtain Al-1Mg-0...

Embodiment 2

[0028] The constituent elements of the bar are: Mg 2wt%, Sc 0.4wt%, Al 98.6wt%, Fe, Si and other impurity elements content ≤ 0.1wt%.

[0029] According to the ratio, put the aluminum ingot with a purity ≥99.9% in a graphite crucible of an intermediate frequency induction melting furnace to melt it. After it is completely melted, the temperature of the molten aluminum is 660-670°C, and then add magnesium with a purity ≥99.9% to the molten aluminum. Ingot and Al-2%Sc master alloy, heat up to 730°C for full stirring after melting the alloy, refine and degas at 720°C after standing for 20 minutes, stand for 20 minutes after removing slag from the melt, and quickly pour the molten metal at 700°C Aluminum alloy casting ingot; brighten the surface of the ingot, preheat the ingot and carry out hot extrusion according to the extrusion ratio of 25, the extrusion temperature is 300, 350°C, and the heat treatment program is 470°C-2h+120°C-16h +160°C-20min+120°C-16h to obtain Al-2Mg-0.4Sc ...

Embodiment 3

[0031] The constituent elements of the bar are: Mg 5wt%, Sc 0.4wt%, Al 98.6wt%, Fe, Si and other impurity elements content ≤ 0.1wt%.

[0032]According to the ratio, put the aluminum ingot with a purity ≥99.9% in a graphite crucible of an intermediate frequency induction melting furnace to melt it. After it is completely melted, the temperature of the molten aluminum is 660-670°C, and then add magnesium with a purity ≥99.9% to the molten aluminum. Ingot and Al-2%Sc master alloy, heat up to 730°C for full stirring after melting the alloy, refine and degas at 720°C after standing for 20 minutes, stand for 20 minutes after removing slag from the melt, and quickly pour the molten metal at 700°C Aluminum alloy casting ingot; brighten the surface of the ingot, preheat the ingot and carry out hot extrusion according to the extrusion ratio of 25, the extrusion temperature is 300, 350°C, and the heat treatment program is 470°C-2h+120°C-16h +160°C-20min+120°C-16h to obtain Al-5Mg-0.4Sc a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com