A metal-doped modified layered δ-mno 2 and its preparation and application

A metal doping and modification layer technology, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve VOCs emissions, environmental pollution, high volatility, etc. problems, to achieve the effects of cheap and easy-to-obtain raw materials, long service life, and strong resistance to chlorine poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

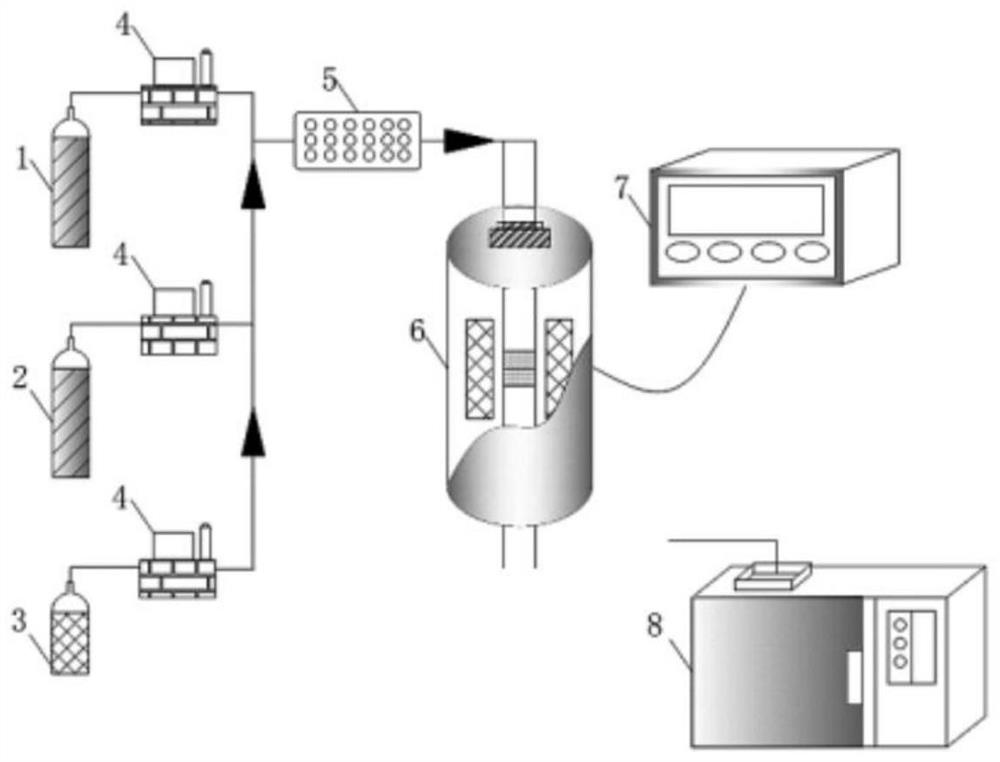

[0047] Another object of the present invention is to provide a metal-doped modified layered δ-MnO 2 The preparation method comprises the following steps:

[0048] Step 1: feed;

[0049] Step 2: react under the set reaction conditions;

[0050] Step 3: post-processing the system obtained in step 2 to obtain the final product.

[0051] Metal-doped modified layered δ-MnO in the present invention 2 The preparation method is the hydrothermal method. Compared with other powder preparation methods such as sol-gel method and high-temperature solid-phase method, the powder prepared by hydrothermal method has complete grain development, small particle size, uniform distribution, light particle agglomeration, and cheaper raw materials can be used , easy to obtain suitable stoichiometry and crystal form.

[0052] Step 1, feed;

[0053] In step 1, the addition is adding a manganese-containing compound, wherein the manganese-containing compound is potassium manganate, potassium perman...

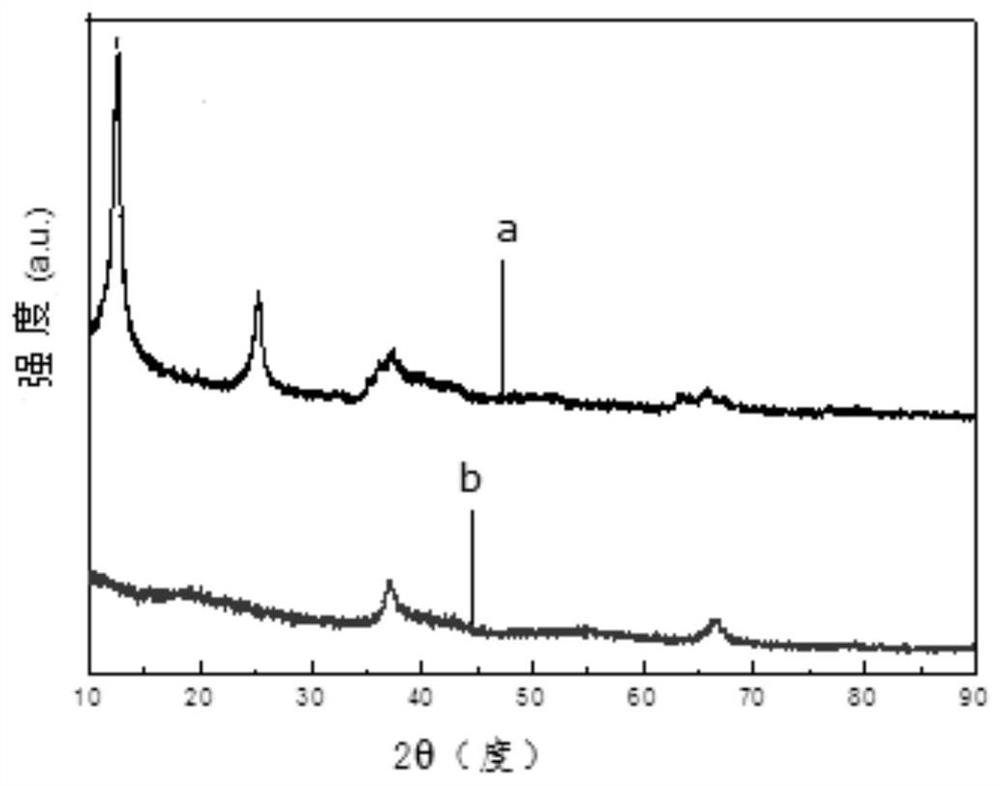

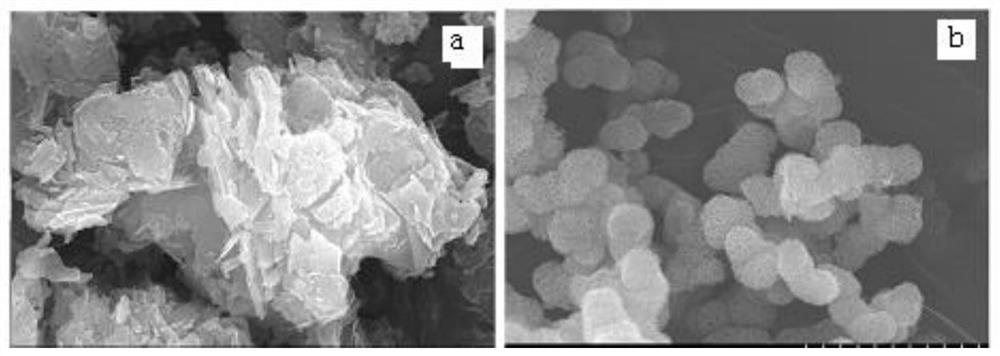

Embodiment 1

[0104] Add 70ml deionized water to the hydrothermal kettle, then add 1.58g KMnO 4 , 1.87g Al(NO 3 ) 3 ·H 2 O was added to the hydrothermal kettle, and stirred in deionized water for 30min, then 2ml of ammoniacal liquor of 0.15mol / L was added;

[0105] Then react the added raw materials in a hydrothermal kettle at 160°C for 12 hours, and the reaction ends;

[0106] Filter the solid-liquid mixture of the reaction liquid in the hydrothermal kettle, and wash the filter cake with deionized water until the pH value of the filtrate is 7 to obtain the filter cake; then dry the filter cake at 80°C for 12 hours to obtain the metal-doped modified layered δ-MnO 2 .

Embodiment 2

[0108] Add 70ml deionized water to the hydrothermal kettle, then add 1.58g KMnO 4 , 1.87g Al(NO 3 ) 3 ·H 2 O was added to the hydrothermal kettle, and stirred in deionized water for 30min, then 2ml of citric acid of 0.15mol / L was added;

[0109] Then react the added raw materials in a hydrothermal kettle at 160°C for 12 hours, and the reaction ends;

[0110] Filter the solid-liquid mixture of the reaction liquid in the hydrothermal kettle, and wash the filter cake with deionized water until the pH value of the filtrate is 7 to obtain the filter cake; then dry the filter cake at 80°C for 12 hours to obtain the metal-doped modified layered δ-MnO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com