A kind of polysulfide maleimide optical resin and preparation method thereof

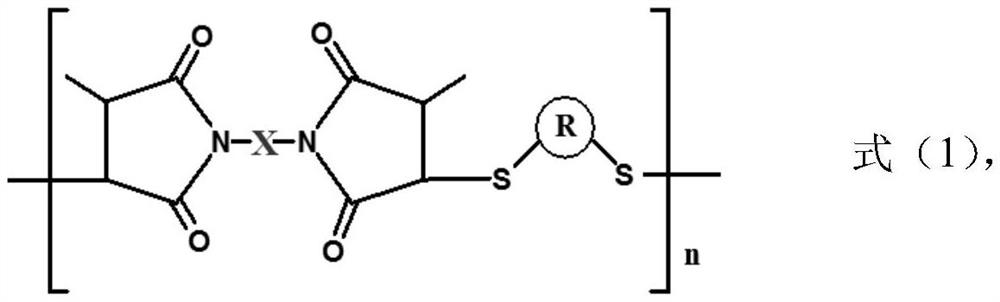

A technology of maleimide and dimethylmaleimide, applied to polythioether maleimide optical resin with high refractive index and high transparency and its preparation, polythioether maleimide In the field of optical resin and its preparation, it can solve the problems of little research on polyimide resin, achieve the effect of controllable product structure, increase refractive index, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

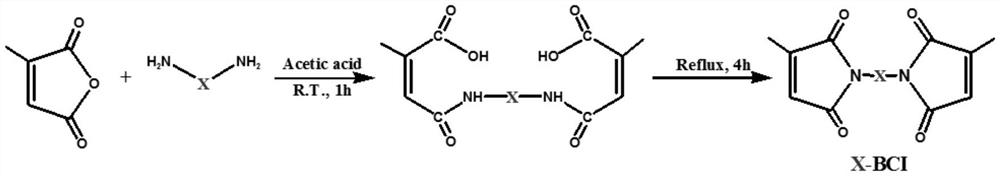

[0044] A polysulfide-eatel maleimide optical resin, which is prepared by the following steps:

[0045] The methyl maleic anhydride (10.5 mmol) of glacial acetic acid (50 mL) was added dropwise to Icevene (100 mL) solution containing 4,4'-diaminobenzol (DDS, 5 mmol), and stirred at room temperature for 1 h. The reaction mixture was then heated to reflux for 4 h, concentrated under reduced pressure and cooled to 200 ml of water. Filter the formed solids and use a 100 ml mass percent concentration of 3% NA 2 CO 3The solution was washed, then washed with deionized water, and 12 h was dried at 70 ° C in a vacuum oven to give a white solid, acetone recrystallization was recrystallized to give 4,4'-di amino diphenyl sulfur double methylimide. (DDS-BCI).

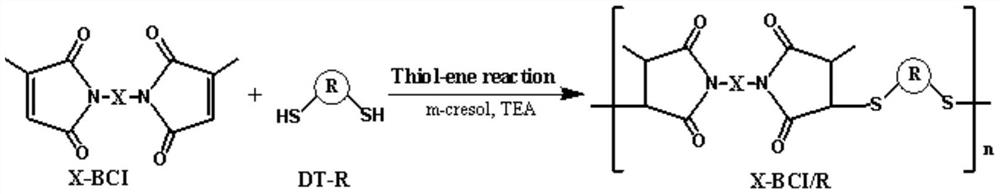

[0046] The mixed 4,4'-diaminophenyl sulfone-based double-methylbenyleimide monomer and dimercaramide sulfide are reacted, and the mephen solvent is dissolved, the initiator is added, stirred at 30 ° C. 4 hours. Among them, the initiator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com