Coating preparation method based on hard alloy substrate surface nanocrystallization

A cemented carbide substrate, nanotechnology, applied in the direction of metal material coating process, coating, ion implantation plating, etc., to achieve the effect of expanding the application range, high diffusion coefficient, and improving penetration depth and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The coating preparation method based on the surface nanometerization of the cemented carbide substrate is specifically carried out according to the following steps:

[0048] S1, base material preparation: Use a diamond grinding disc to grind the surface of the YG8 cemented carbide base material according to 80 #, 180 #, 400 #, 600 #, 800 #, 1000 #, 1200 #, 1500 #, and then polish it. It is smooth and clean;

[0049] S2, cleaning the surface of the matrix material: ultrasonically clean the matrix material obtained in step S1 in an acetone solution for 30 minutes, and dry it with a hair dryer after cleaning;

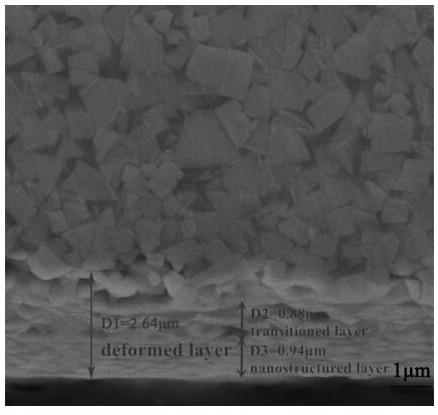

[0050] S3, surface nanometerization of the base material: the base material obtained in step S2 is subjected to ultrasonic shot peening surface nanometerization treatment to obtain a gradient nanocrystalline / microcrystalline deformed layer; the shot peening medium is stainless steel balls, hard alloy balls, and alumina ceramic balls At least one of these; peening m...

Embodiment 2

[0055] The coating preparation method based on the surface nanometerization of the cemented carbide substrate is specifically carried out according to the following steps:

[0056] S1, base material preparation: Use a diamond grinding disc to grind the surface of the YG8 cemented carbide base material according to 80 #, 180 #, 400 #, 600 #, 800 #, 1000 #, 1200 #, 1500 #, and then polish it. It is smooth and clean;

[0057] S2, cleaning the surface of the matrix material: ultrasonically clean the matrix material obtained in step S1 in an acetone solution for 30 minutes, and dry it with a hair dryer after cleaning;

[0058] S3, nanometerization of the surface of the base material: the base material obtained in step S2 is subjected to ultrasonic rolling surface nanometerization treatment, the indenter is a hard alloy ball with a diameter of 14mm, the ultrasonic frequency is 28KHz, and the reduction is 0.05-0.1mm; : 0.1-0.6MPa;

[0059] S4, coating preparation: after the base ma...

Embodiment 3

[0063] The coating preparation method based on the surface nanometerization of the cemented carbide substrate is specifically carried out according to the following steps:

[0064] S1, base material preparation: Use a diamond grinding disc to grind the surface of the YG8 cemented carbide base material according to 80 #, 180 #, 400 #, 600 #, 800 #, 1000 #, 1200 #, 1500 #, and then polish it. It is smooth and clean;

[0065] S2, cleaning the surface of the matrix material: ultrasonically clean the matrix material obtained in step S1 in an acetone solution for 30 minutes, and dry it with a hair dryer after cleaning;

[0066] S3, surface nanometerization of the matrix material: the matrix material obtained in step S2 is subjected to ultrasonic impact surface nanometerization treatment, and the material of the impact needle is mold steel; frequency: 15-20 KHz;

[0067] Step S4, coating preparation: after the base material obtained in step S3 was ultrasonically cleaned and dried, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com