A flexible pressure sensor based on biomaterial sunflower flower pollen and titanium carbide composite material and its preparation method

A pressure sensor, biomaterial technology, applied in the direction of instrumentation, force measurement, force/torque/power measuring instrument calibration/testing, etc., can solve a wide range of applications, unsatisfactory response time and sensitivity performance, poor conductivity Ability and other issues, achieve low detection limit, easy to operate the production process, improve the effect of detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

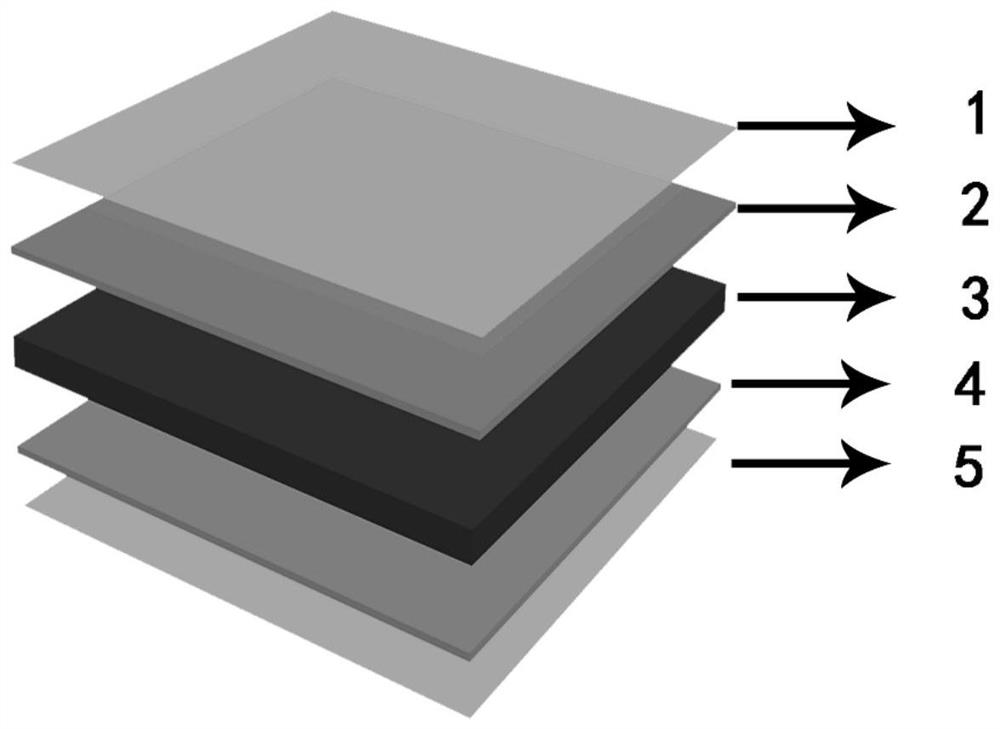

[0034] (1) Purchase commercial polyethylene diformate (PI) with a thickness of 80 μm and polydimethylsiloxane (PDMS) flexible materials with a thickness of 80 μm, ultrasonically clean them with acetone, ethanol, and water for 10 minutes, and dry Dry to obtain a flexible substrate, respectively as an upper flexible substrate and a lower flexible substrate;

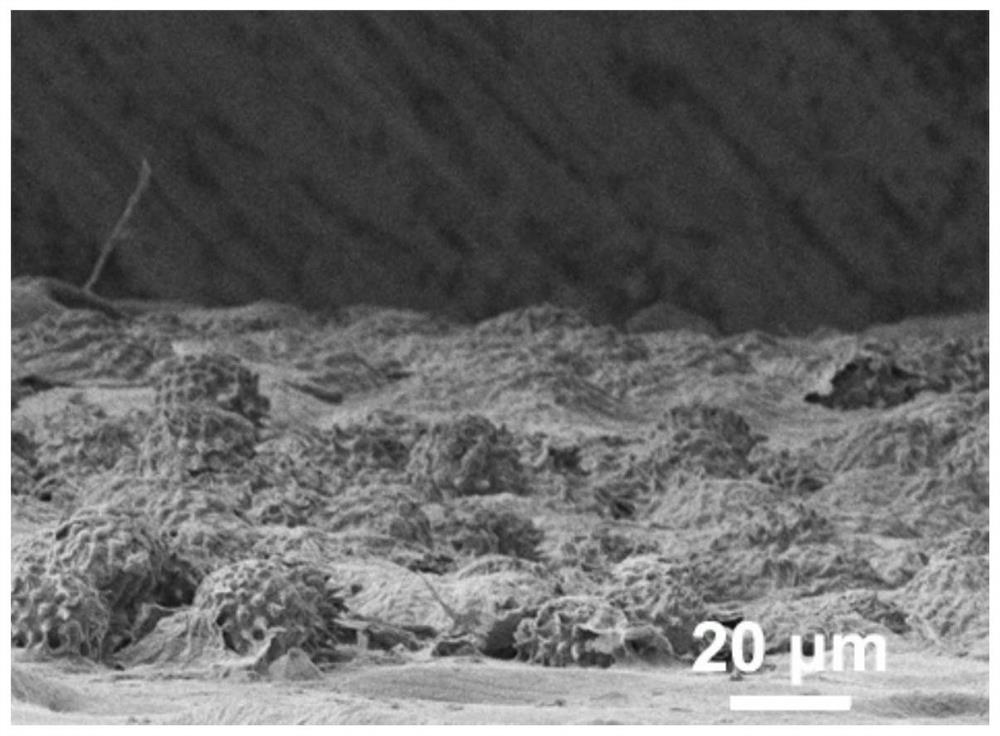

[0035] (2) Preparation of titanium carbide solution: Add 2.4g of lithium fluoride (LiF) into 30mL of 9M hydrochloric acid (HCl) solution and stir for 5min, then mix 1.5g of titanium aluminum carbon (Ti 3 AlC 2) was slowly added to the above solution, then transferred to a polytetrafluoroethylene reactor, stirred and heated in an oil bath at 30°C for 48 hours, and after taking it out, added a sulfuric acid solution with a concentration of 2M and a volume of 10mL, and then centrifuged at 3500rpm for 5min. After removing the supernatant, add 10 mL of deionized water, centrifuge and wash at 3500 rpm until the pH is 6, collect ...

Embodiment 2

[0042] (1) Purchase commercial polyethylene terephthalate (PET) with a thickness of 60 μm and polydimethylsiloxane (PDMS) flexible substrate film with a thickness of 80 μm, and use acetone, ethanol, and water to ultrasonically Wash for 10 minutes and dry to obtain flexible substrates, which are respectively used as upper flexible substrate and lower flexible substrate;

[0043] (2) Preparation of titanium carbide solution: 2.4g of lithium fluoride (LiF) was added to 30mL of 9M hydrochloric acid (HCl) solution and stirred for 5min, and 1.5g of titanium aluminum carbon (Ti 3 AlC 2 ) was slowly added to the above solution, then transferred to a polytetrafluoroethylene reaction kettle, stirred and heated in an oil bath at 30°C for 48 hours, after taking it out, added a sulfuric acid solution with a concentration of 2M and a volume of 10mL, and then centrifuged at 3500rpm for 5min to remove Add 10 mL of deionized water after the supernatant, and centrifuge at 3500 rpm until the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com