Preparation method and application of niobium diselenide as electrode material of sodium-ion battery

A sodium-ion battery, niobium diselenide technology, which is applied in the fields of energy storage materials and chemical power sources, can solve the problems of battery capacity attenuation, microstructure damage of electrode materials, and limited application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

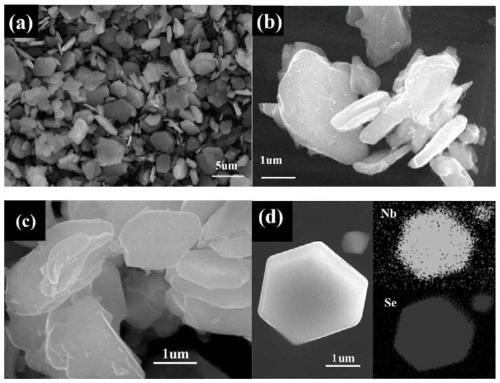

Image

Examples

Embodiment 1

[0027] Mix 1g of niobium powder and 2g of selenium powder evenly by dry ball milling for 4 hours, sinter in a tube furnace under argon atmosphere, heat up to 650°C at a rate of 5°C / min and keep at constant temperature for 2h , naturally cooled to room temperature to obtain the product sodium ion battery electrode material niobium diselenide.

Embodiment 2

[0029] 0.93g of niobium powder and 1.975g of selenium powder were mixed evenly by manual grinding, the mixing time was 2h, and sintering was carried out in a tube furnace under vacuum, and the temperature was raised to 750°C at a rate of 10°C / min and kept at a constant temperature for 3h. Cool naturally to room temperature to obtain the product niobium diselenide, an electrode material for sodium ion batteries.

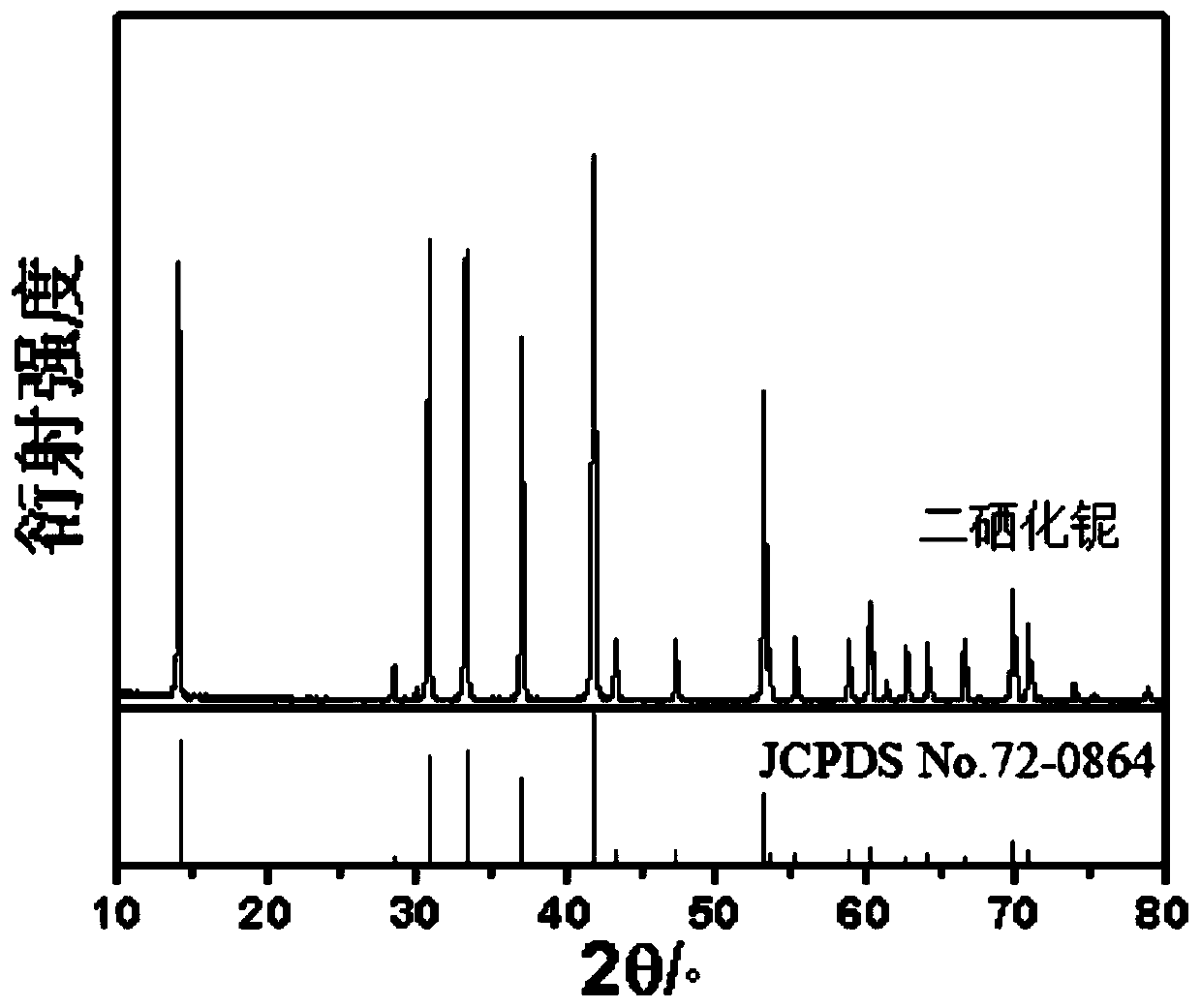

[0030] figure 1 It is the XRD spectrum of the niobium diselenide material, as can be seen from the figure, the peak position of the XRD spectrum of the material is well consistent with the peak position and peak intensity on the standard card (JCPDS No.72-0864), indicating that the preparation The composition of the resulting material is phase-pure NbSe2.

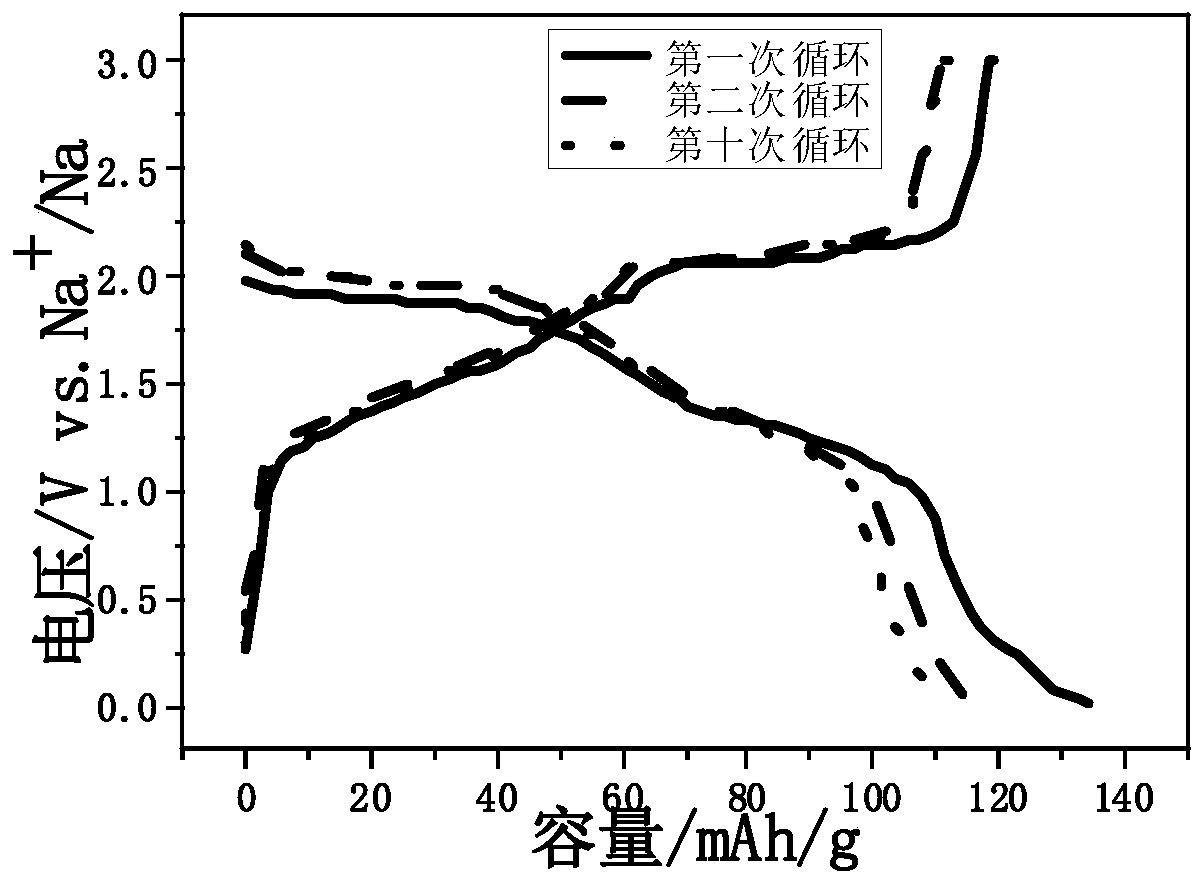

[0031] figure 2 It is the 1st, 2nd and 10th charge and discharge curves of niobium diselenide material. As shown in the figure, there are similar curves in the discharge process of different cycles, that is, an ...

Embodiment 3

[0035] Mix 1.1g of niobium powder and 2.2g of selenium powder uniformly by magnetic force for 2 hours, sinter in a tube furnace under argon atmosphere, raise the temperature to 800°C at a rate of 15°C / min and keep it at a constant temperature for 10h , naturally cooled to room temperature to obtain the product sodium ion battery electrode material niobium diselenide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com