A kind of Cu alloyed deep drawing dual-phase steel plate and preparation method thereof

An alloying and steel plate technology, applied in the field of metal material processing, can solve the problems of unfavorable economical production, cold brittleness, and difficulty in precise control, and achieve the effects of good shape and surface quality, improved deep-drawing performance, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

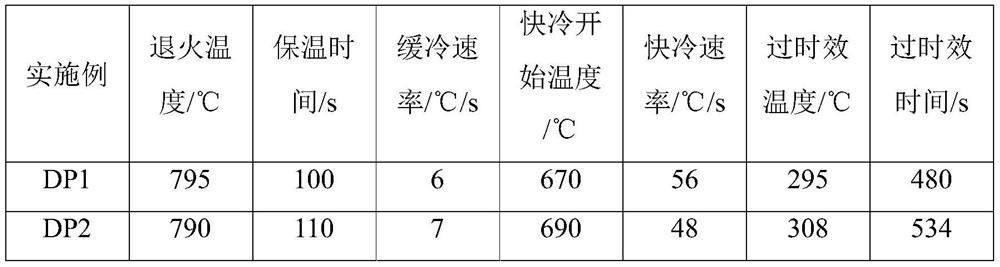

[0025] The following examples are implemented on the premise of the technical solutions of the present invention, and detailed implementation methods and specific operation processes are provided, but the protection scope of the present invention is not limited to the following examples. The methods used in the following examples are conventional production methods unless otherwise specified. The chemical composition of the Cu-alloyed deep-drawing dual-phase steel sheet in the examples is shown in Table 1.

[0026] Table 1 chemical composition (mass percentage: %)

[0027] Numbering C Si mn P S Cu Ni Ti N DP1 0.021 0.18 0.22 0.016 0.0026 0.45 0.37 0.018 0.0033 DP2 0.028 0.26 0.16 0.012 0.0023 0.53 0.42 0.021 0.0036

[0028] Smelt and forge according to the chemical composition in Table 1. In order to prevent Cu from forming cracks on the surface during the hot rolling process, a lower heating temperature is used, the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com