Preparation method of CuFeO2 semiconductor

A semiconductor, cuso4-technology, applied in the direction of electrode, electrolytic inorganic material coating, electrolytic process, etc., can solve the problems that affect the stability of semiconductors, light corrosion, reduce water decomposition efficiency, etc., achieve excellent light stability and reduce light corrosion , The effect of Faraday efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

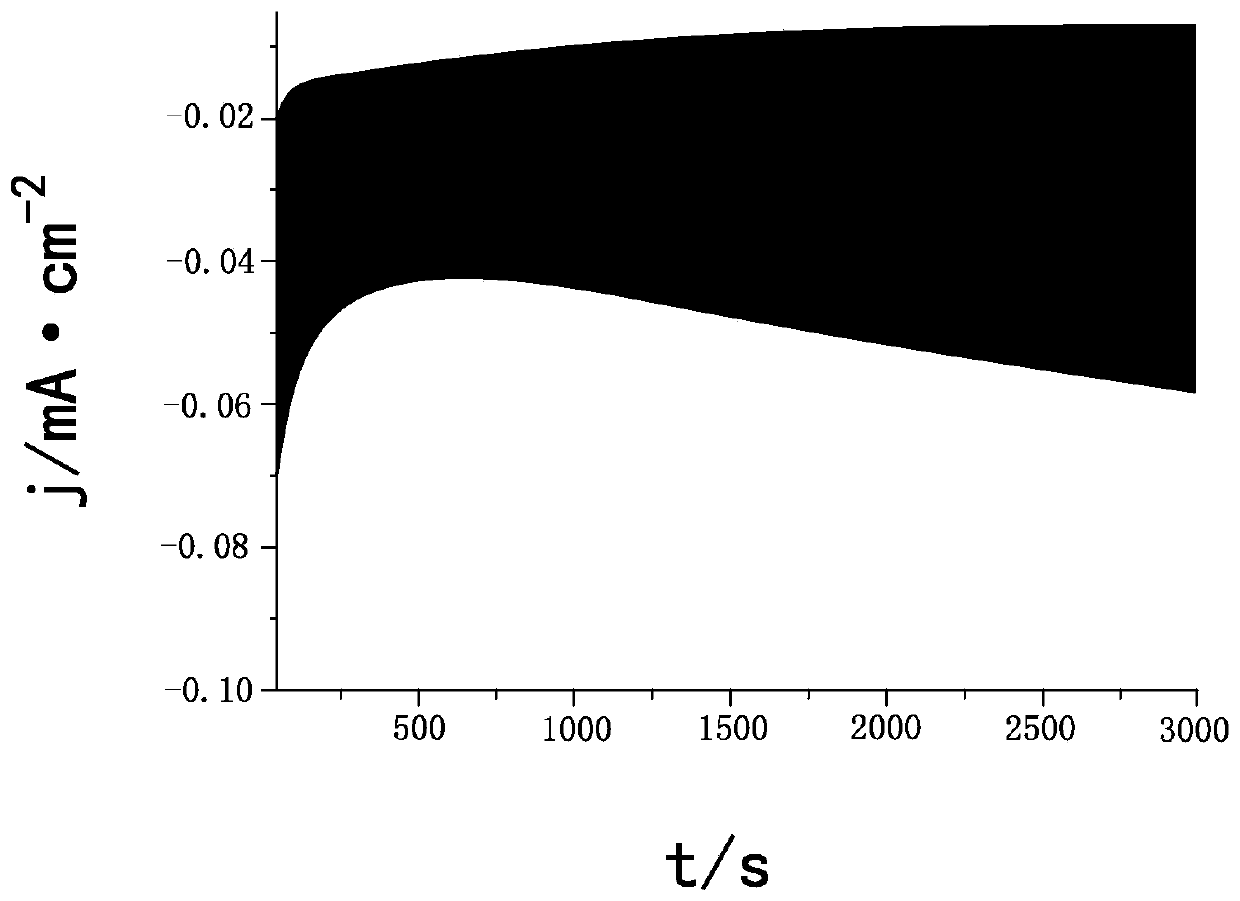

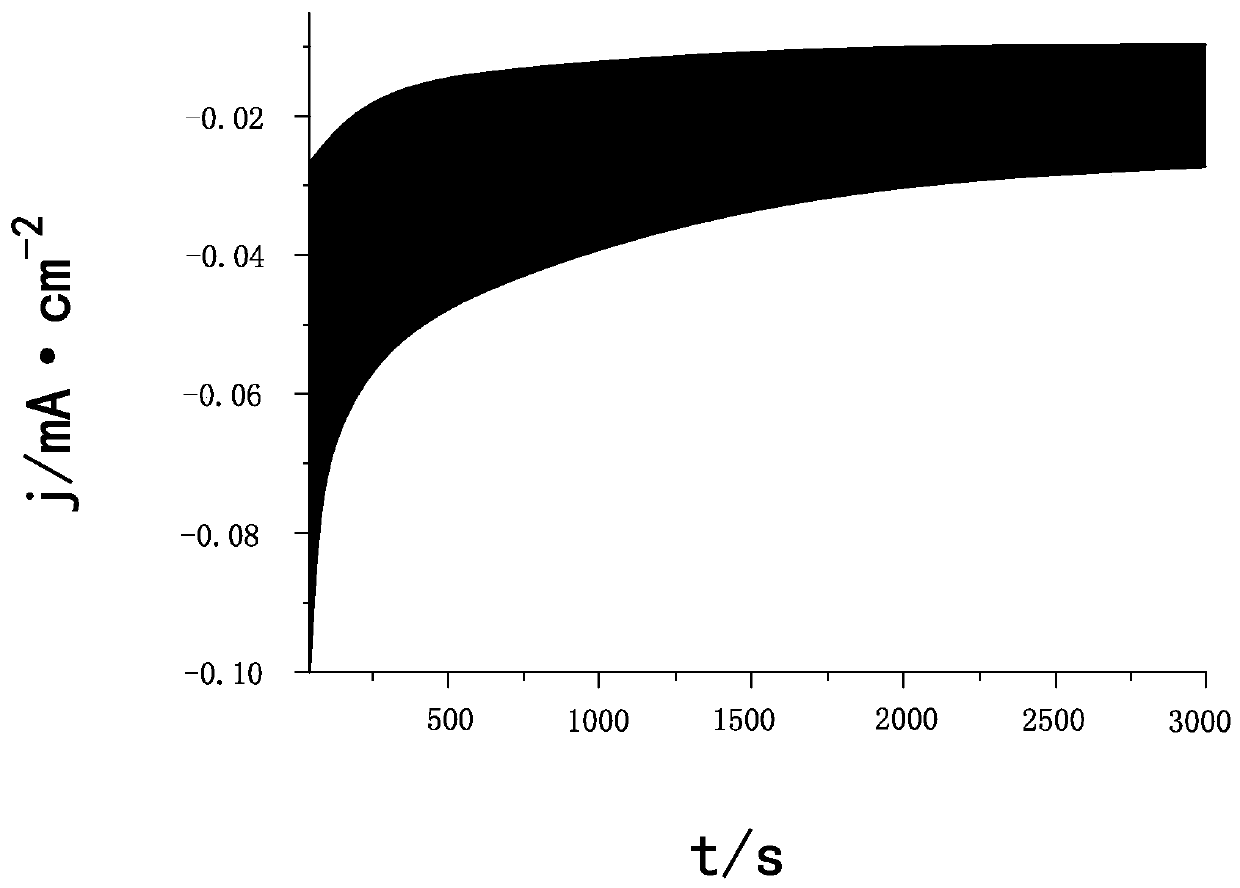

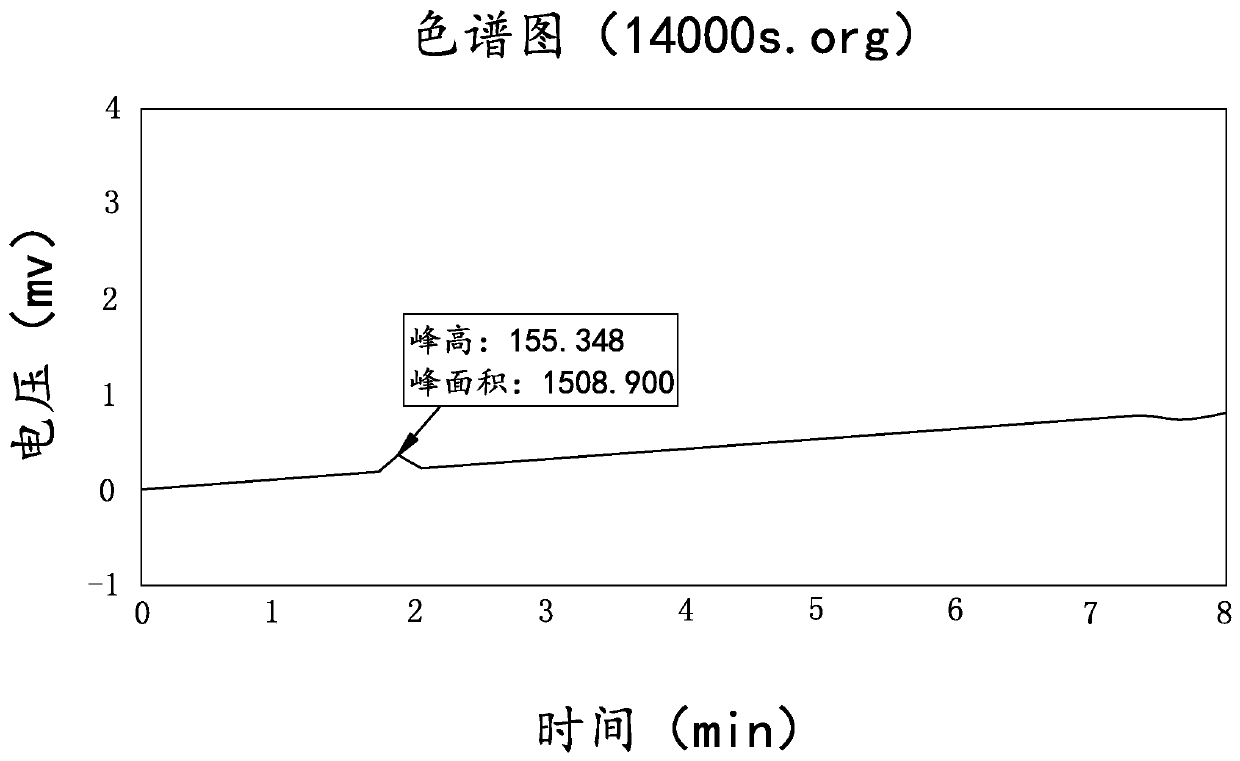

Embodiment 1

[0024] a CuFeO 2 A method for preparing a semiconductor, comprising the steps of:

[0025] (1) Add CuSO to lactic acid solution 4 solution, after mixing uniformly to obtain CuSO 4 - Lactic acid mixed solution, the resulting CuSO 4 -The concentration of lactic acid in the lactic acid mixed solution is 0.25mol / L, CuSO 4 The concentration is 0.4mol / L;

[0026] (2) CuSO prepared in step (1) 4 -Add FeCl to lactic acid mixed solution 3 , the added FeCl 3 The concentration is 0.05mol / L, and magnetic stirring is used to make FeCl 3 dissolved and mixed with CuSO 4 - Lactic acid mixed solution is mixed evenly to prepare CuFeO 2 Electrodeposition solution;

[0027] (3) CuFeO prepared in step (2) 2 Add alkaline solution to the electrodeposition solution, the alkaline solution used is NaOH solution, adjust CuFeO 2 The pH value of the electrodeposition solution is 7.0;

[0028] (4) ITO conductive glass is put into acetone, ethanol and ultrapure water successively to clean;

[...

Embodiment 2

[0031] a CuFeO 2 A method for preparing a semiconductor, comprising the steps of:

[0032] (1) Add CuSO to lactic acid solution 4 solution, after mixing uniformly to obtain CuSO 4 - Lactic acid mixed solution, the resulting CuSO 4 -The concentration of lactic acid in the lactic acid mixed solution is 0.35mol / L, CuSO 4 The concentration is 0.6mol / L;

[0033] (2) CuSO prepared in step (1) 4 -Add FeCl to lactic acid mixed solution 3 , the added FeCl 3 The concentration is 0.5mol / L, and magnetic stirring is used to make FeCl 3 dissolved and mixed with CuSO 4 - Lactic acid mixed solution is mixed evenly to prepare CuFeO 2 Electrodeposition solution;

[0034] (3) CuFeO prepared in step (2) 2 Add alkaline solution to the electrodeposition solution, the alkaline solution used is NaOH solution, adjust CuFeO 2 The pH value of the electrodeposition solution is 9.5;

[0035] (4) ITO conductive glass is put into acetone, ethanol and ultrapure water successively to clean;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com