Asphalt transportation device and production method thereof

A technology of transportation device and production method, which is applied in the direction of transportation and packaging, household refrigeration equipment, packaging, etc., and can solve the problems of expensive materials, difficult fixing of tank bodies, and difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

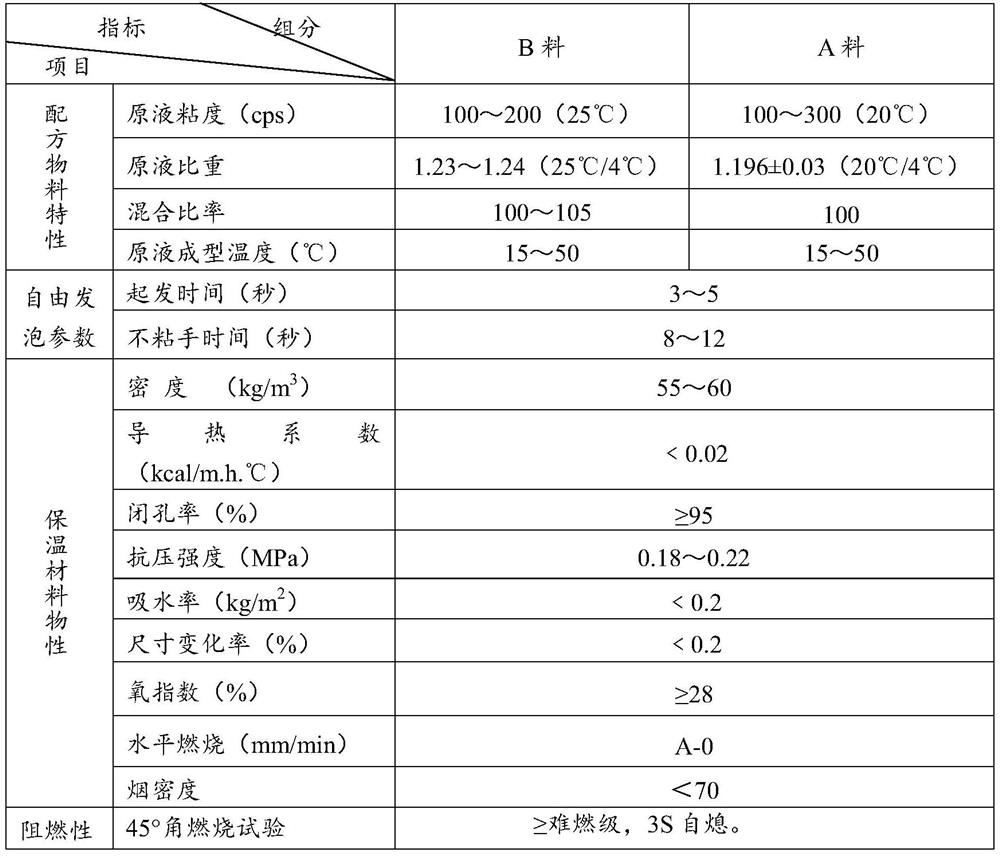

[0028] The formula for the production of insulation material layers for asphalt transport units is as follows:

[0029] Material A is diphenylmethane diisocyanate;

[0030]B material comprises that the molecular weight of 40 parts by weight is the polyether triol of 2000, the molecular weight of 25 parts by weight is the polyester polyol of 1500, the graft polyether 403 (the molecular weight is the ethylenediamine of 300 that the molecular weight of 5 parts by weight is 300 Polyether tetraol, made from ethylenediamine and propylene oxide (propylene oxide), 15 parts by weight of dimethyl methylphosphonate, 3 parts by weight of silicone oil, 3 parts by weight of K-15, 3 parts by weight of water;

[0031] Producing an asphalt transport unit includes the following steps:

[0032] 1) Use compressed air to blow the surface of the tank body of the asphalt transportation device that needs to be kept warm, and cover and protect the parts and components that do not need to be sprayed w...

Embodiment 2

[0040] The formula for the production of insulation material layers for asphalt transport units is as follows:

[0041] Material A is diphenylmethane diisocyanate;

[0042] Material B includes 40 parts by weight of polyether triol with a molecular weight of 3000, 25 parts by weight of polyester polyol with a molecular weight of 2500, grafted polyether 3630 with a molecular weight of 400, and 15 parts by weight of methylphosphonic acid diol. Methyl ester, 3 parts by weight of silicone oil, 3 parts by weight of triazine PC-41, and 3 parts by weight of water.

[0043] Producing an asphalt transport unit includes the following steps:

[0044] 1) Use compressed air to blow the surface of the tank body of the asphalt transportation device that needs to be kept warm, and cover and protect the parts and components that do not need to be sprayed with a masking film;

[0045] 2) Pour material A and material B into their respective containers and connect to the metering pump; calibrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com