Supercritical carbon dioxide deep cooling treatment method and device and gas recycling system

A technology of carbon dioxide and cryogenic treatment, which is applied in the direction of furnace control devices, refrigerators, refrigeration components, etc., can solve the problems of increased internal stress of workpieces, uneven cooling of workpieces, cracking of workpieces, etc., and achieves fast heat exchange and cooling rate. The effect of high control and cryogenic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

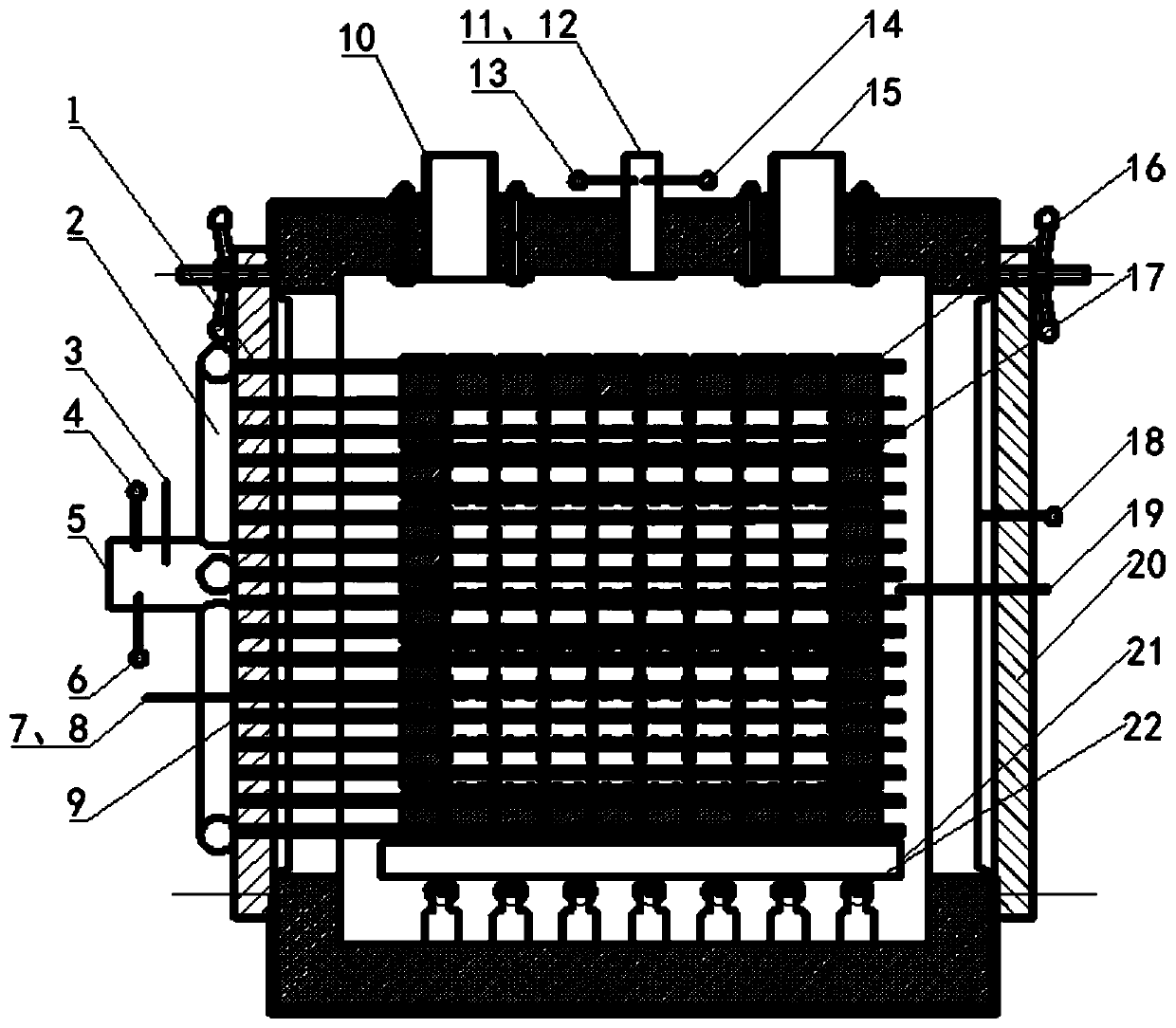

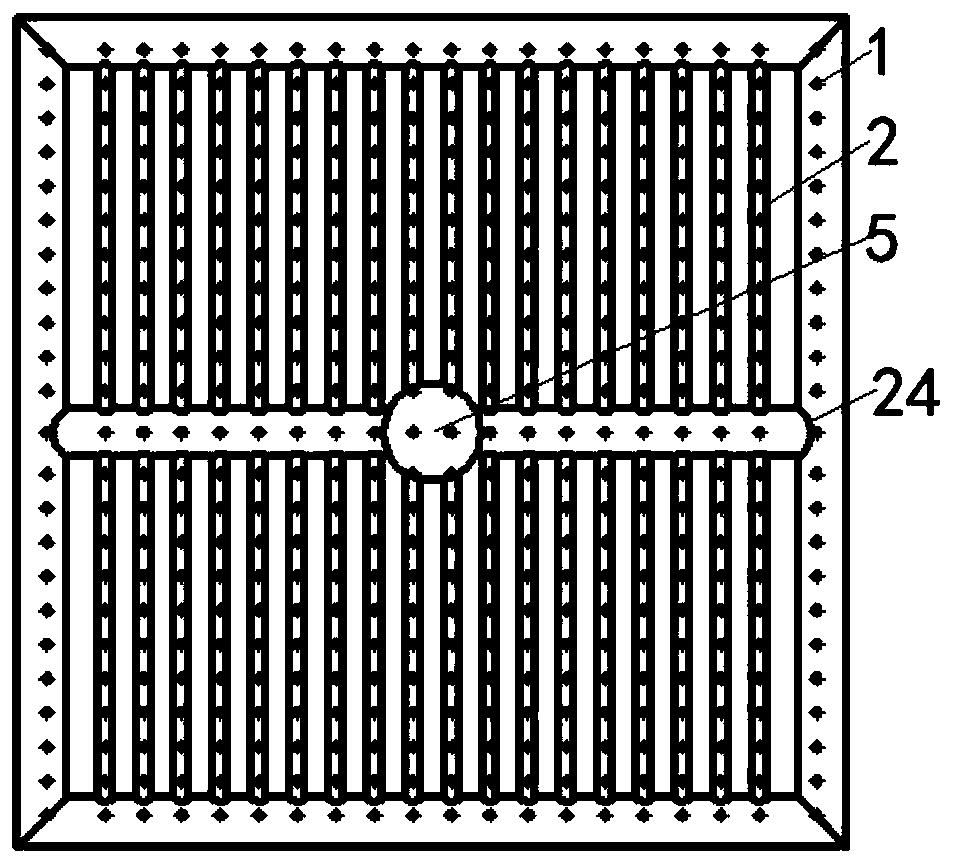

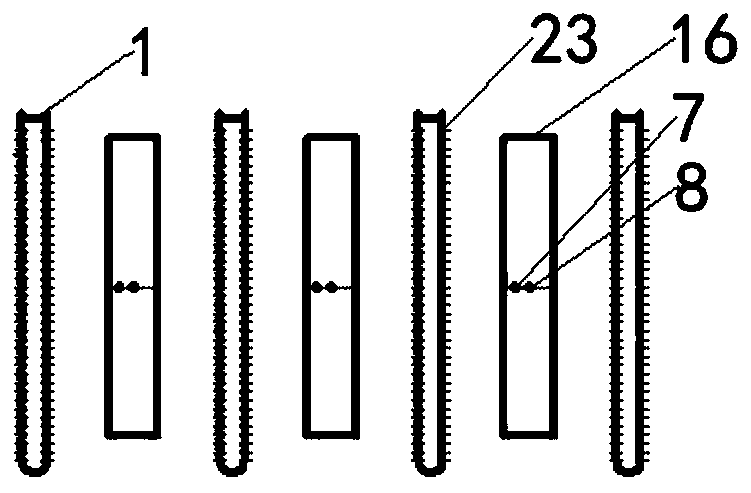

[0058] refer to figure 1 As shown, the present embodiment provides a supercritical carbon dioxide cryogenic treatment device, including a cryogenic furnace and some jet tubes 1 extending into the furnace from the outside of the furnace and uniformly distributed between workpieces 16, and some of the jet tubes 1 are all connected with The total air intake pipe 5 is connected, and jet pipes of different sizes and models can be replaced according to the requirements of processing workpieces.

[0059] refer to figure 1 As shown, the supercritical carbon dioxide cryogenic treatment device also includes a first thermocouple 3 , a first pressure gauge 4 and a first flowmeter 6 arranged in the main intake pipe 5 one by one. The total intake pipe 5 is inserted with a thermocouple 3 for monitoring the temperature of the gas in the total intake pipe 5 . The total intake pipe 5 is connected with a first pressure gauge 4 for measuring the pressure of gas in the total intake pipe 5 . The...

Embodiment 2

[0069] Based on the supercritical carbon dioxide cryogenic treatment device described in the above-mentioned embodiment 1, this embodiment provides a supercritical carbon dioxide cryogenic treatment method of the device, the cryogenic medium used in the cryogenic treatment method is supercritical carbon dioxide, supercritical carbon dioxide It has a higher density and thermal conductivity than liquid nitrogen, which helps to increase the rate of cryogenic treatment. The supercritical carbon dioxide refers to that the state of the gas in the total intake pipe, shunt pipe and jet pipe is supercritical, the gas injected from the jet is in a non-supercritical state, and the temperature and pressure of the cryogenic furnace are not in a supercritical state. The principle of the supercritical carbon dioxide cryogenic treatment device is to change the gas ejected from the jet tube from a supercritical state to a non-supercritical state to absorb a large amount of heat, thereby causing...

Embodiment 3

[0102] refer to image 3 As shown, based on the supercritical carbon dioxide cryogenic treatment device described in the above-mentioned embodiment 1 and the supercritical carbon dioxide cryogenic treatment method described in the embodiment 2, this embodiment provides a gas recycling system, including cryogenic treatment through pipelines connected in sequence Device 45 , rotary compressor 47 , condenser 48 , carbon dioxide cylinder 25 , liquefied gas tank 30 heat exchanger 34 , supercritical carbon dioxide pump 35 and surge tank 38 .

[0103] refer to image 3 As shown, in this embodiment, the cryogenic treatment device 45 uses supercritical carbon dioxide to carry out cryogenic treatment of the workpiece, and the gaseous carbon dioxide in the process is discharged through the exhaust pipe and / or safety valve at the top; the rotary compression Machine 47 and condenser 48 are used for compressing and liquefying the discharged carbon dioxide gas, and the liquefied carbon diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com