Fully-automatic integrated machine for processing wire head

A fully automatic, all-in-one technology, applied in line/collector parts, cable installation, and equipment for dismantling/armored cables, etc., can solve problems such as low degree of automation, manual feeding, wire fixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0149] Embodiment 1, the concrete structure of the present invention is as follows:

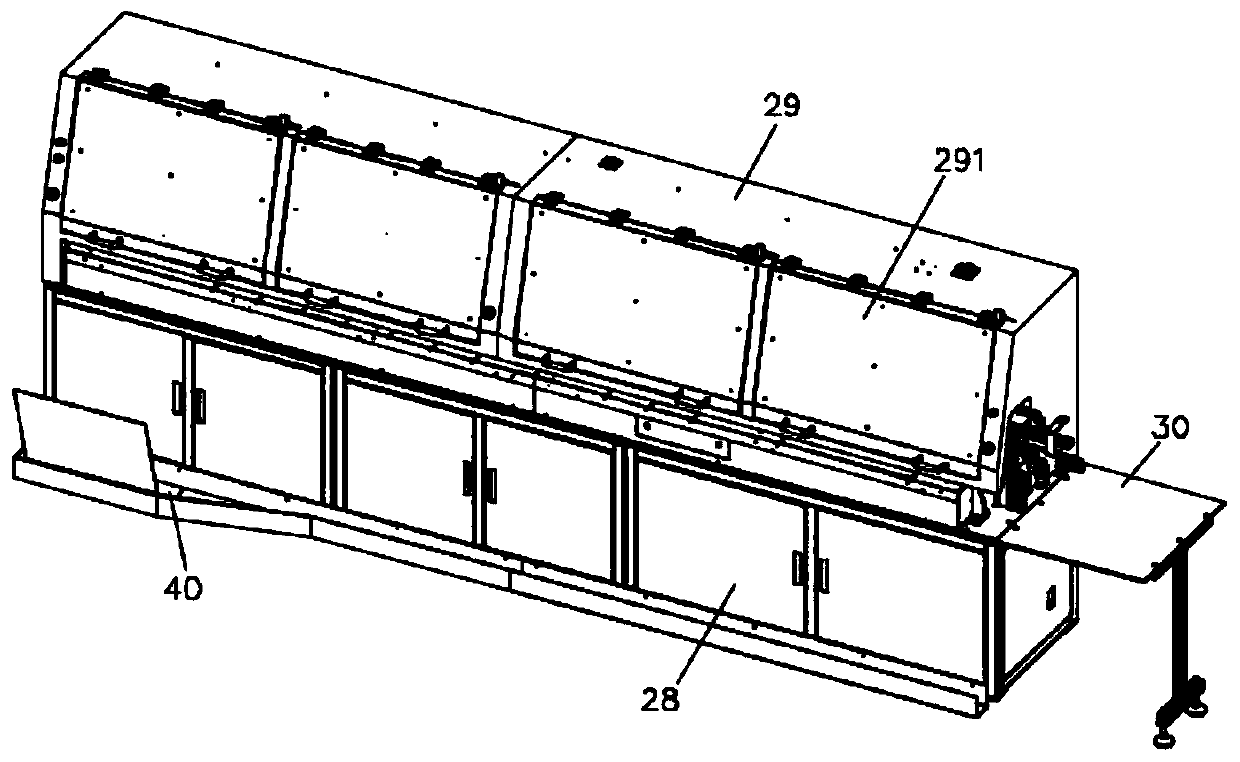

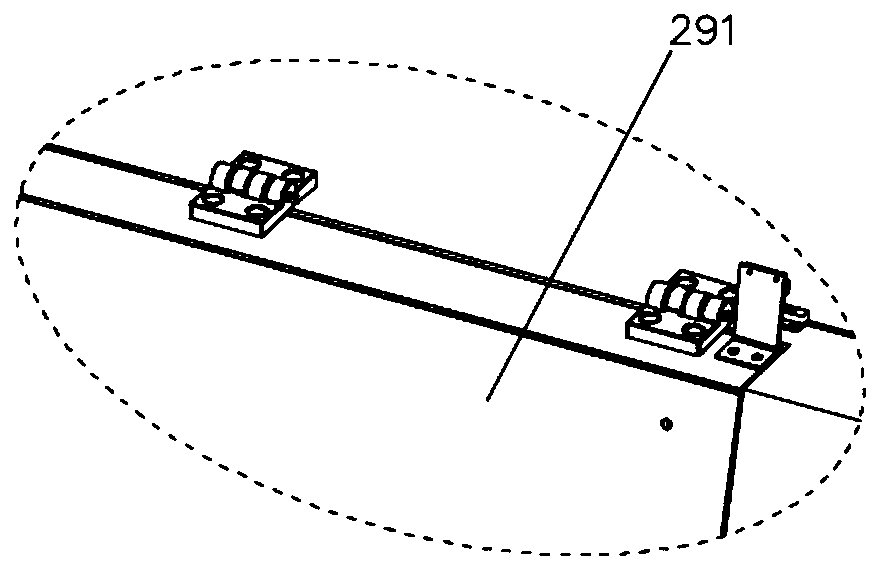

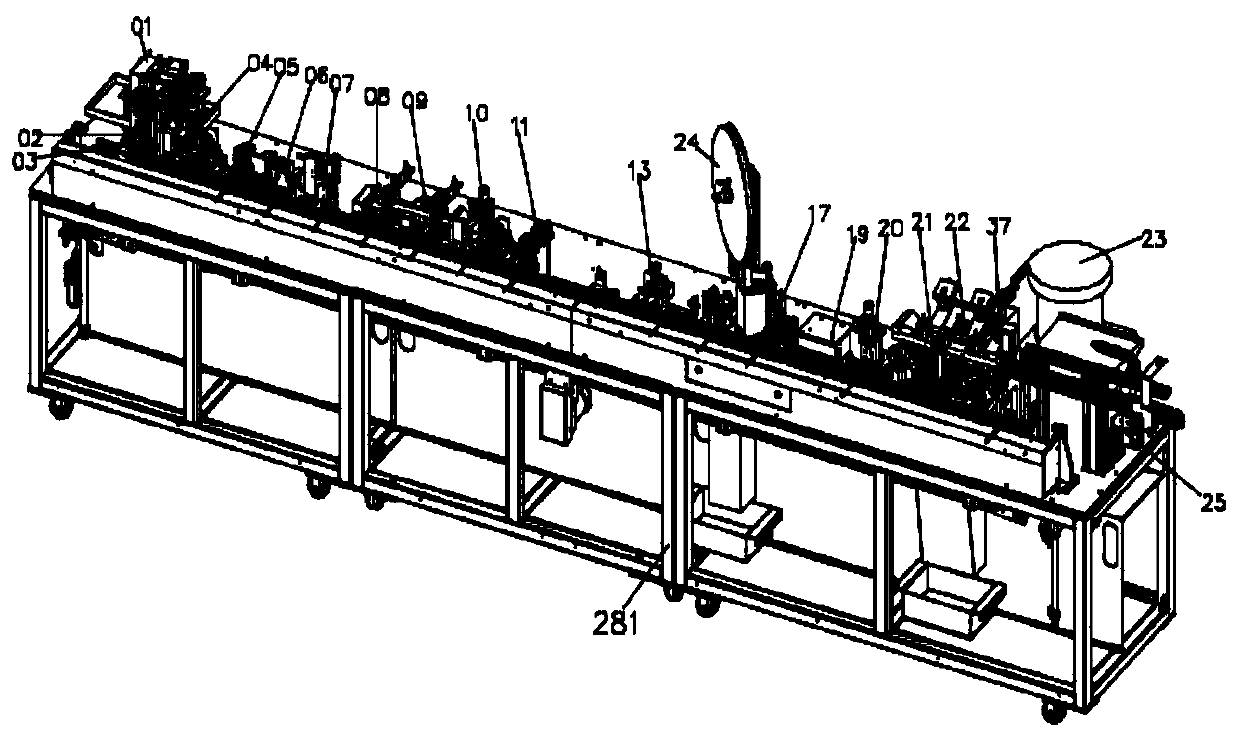

[0150] Please refer to the attached Figure 1-58 , a kind of fully automatic all-in-one machine for processing the head of the wire rod according to the present invention includes a complete machine platform 28, an upper protective frame group 29 is arranged on the upper surface of the complete machine platform 28, and an upper protective frame group 29 is provided on the upper protective frame group 29. The upper opening protective door 291 is hinged with the upper top plate of the upper protective frame group 29. The right side of the complete machine platform 28 is a wire collection platform 30, and the front left part is provided with a protective wire Groove set 40. The left, right and rear frames of the complete machine platform 28 are provided with sealing plates, and double doors are arranged on the front side frame body, and the table panel a11 is arranged on the described complete ...

Embodiment 2

[0231] Embodiment 2: the operating steps of the fully automatic all-in-one machine of the present invention are as follows:

[0232] (1) The coiled wire passes through the wire group, guides it into the wire feeding group, the servo motor drives the wire feeding to reach the precise conveying length, enters the thread cutting group and passes through the wire carrier on the first station, which has passed the opening carrier assembly 1 Open the carrier and wait for the wire to penetrate. When the wire is fed to a fixed length, the first carrier assembly closes the carrier so that the carrier bag clamps the wire, and then the thread cutting group cuts the wire to complete a fixed-length cutting of the wire .

[0233] (2) After the fixed-length cutting of the wire is completed at the first station, the hook carrier push block in the carrier return device performs a reciprocating action to push the carrier from the first station to the second station. Then the crimping anti-slip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com