Light high-conductivity arc tracking-resistant and irradiation-resistant cable for aerospace and manufacturing process thereof

A technology of radiation-resistant cables and high electrical conductivity, applied in the manufacture of cables/conductors, insulation of conductors/cables, insulated cables, etc., can solve the problems of volatile matter deposition, pollution of electrical equipment, corrosion, etc. The effect of reducing the weight of the cable and saving the wiring space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

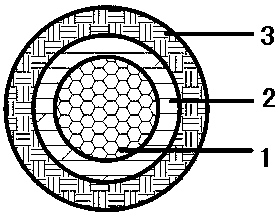

[0033] As shown in the figure, a light-duty, high-conductivity, arc-resistant and radiation-resistant cable for aerospace includes a conductor 1 , an inner insulating layer 2 , and an outer insulating layer 3 .

[0034] The manufacturing process of the light-duty high-conductivity arc-resistant and radiation-resistant cable for aerospace includes the following steps:

[0035] 1) Prepare the conductor:

[0036] The conductor is made of 19 high-conductivity silver-free copper alloys with a diameter of 0.20 mm and is tightly stranded, which makes the surface of the conductor smooth and burr-free;

[0037] 2) Wrapped inner insulating layer:

[0038] Wrap 2 layers of modified polysiloxane-polyimide composite film with a thickness of 0.03mm on the outside of the conductor to form an inner insulating layer with a wrapping overlapping rate of 50-54%; After wrapping the inner insulation layer, put it into a 3-meter-long sintering furnace for sintering at a high temperature of 800°C t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com