Continuous chromatographic device and panax notoginseng saponin production method

A continuous chromatography and chromatographic column technology, applied in the field of traditional Chinese medicine separation, can solve the problems of retention, inability to achieve continuity, large-scale production, uncontrollable membrane flux, etc., and achieve continuous collection, continuous automation and large-scale effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

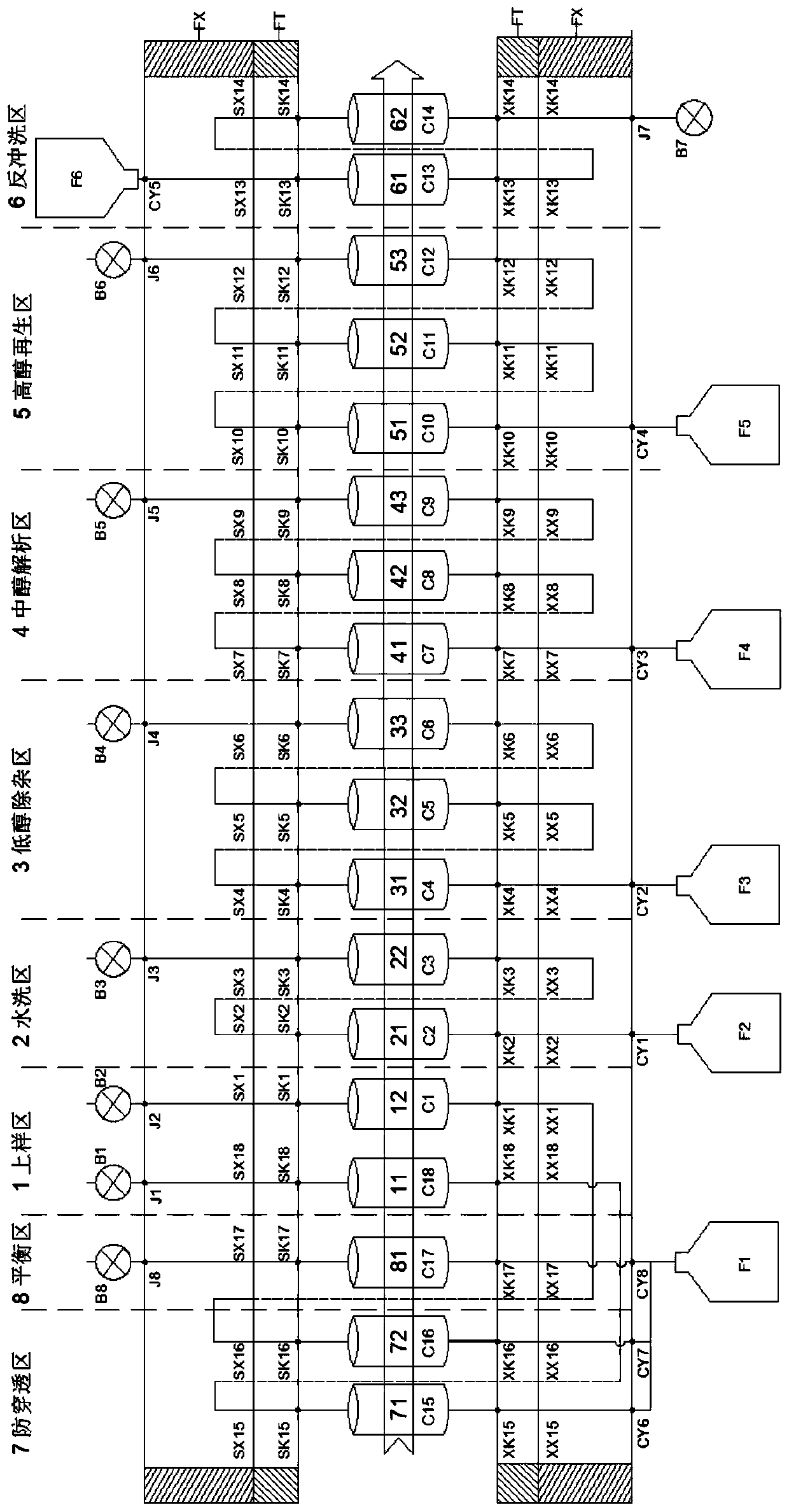

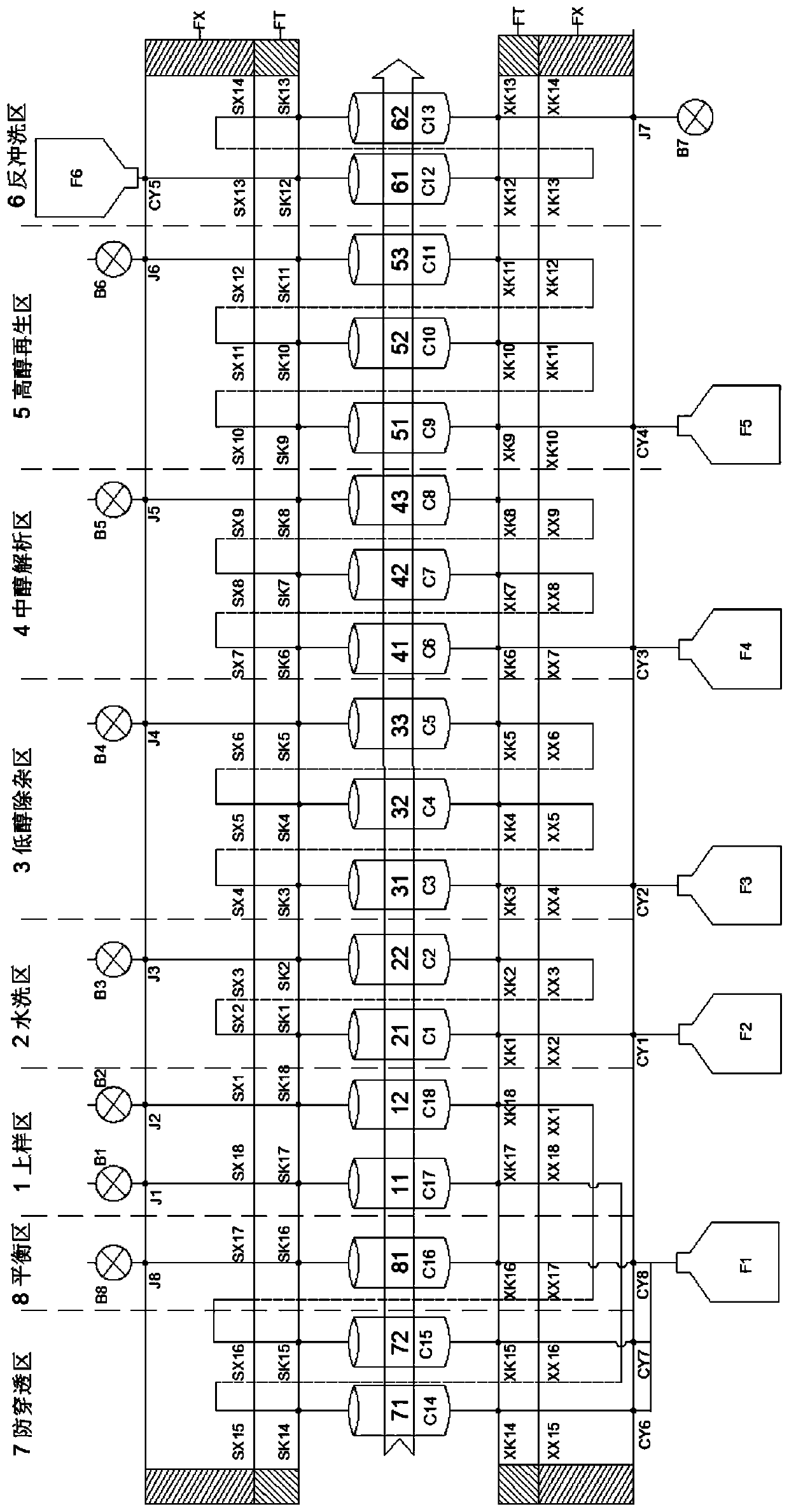

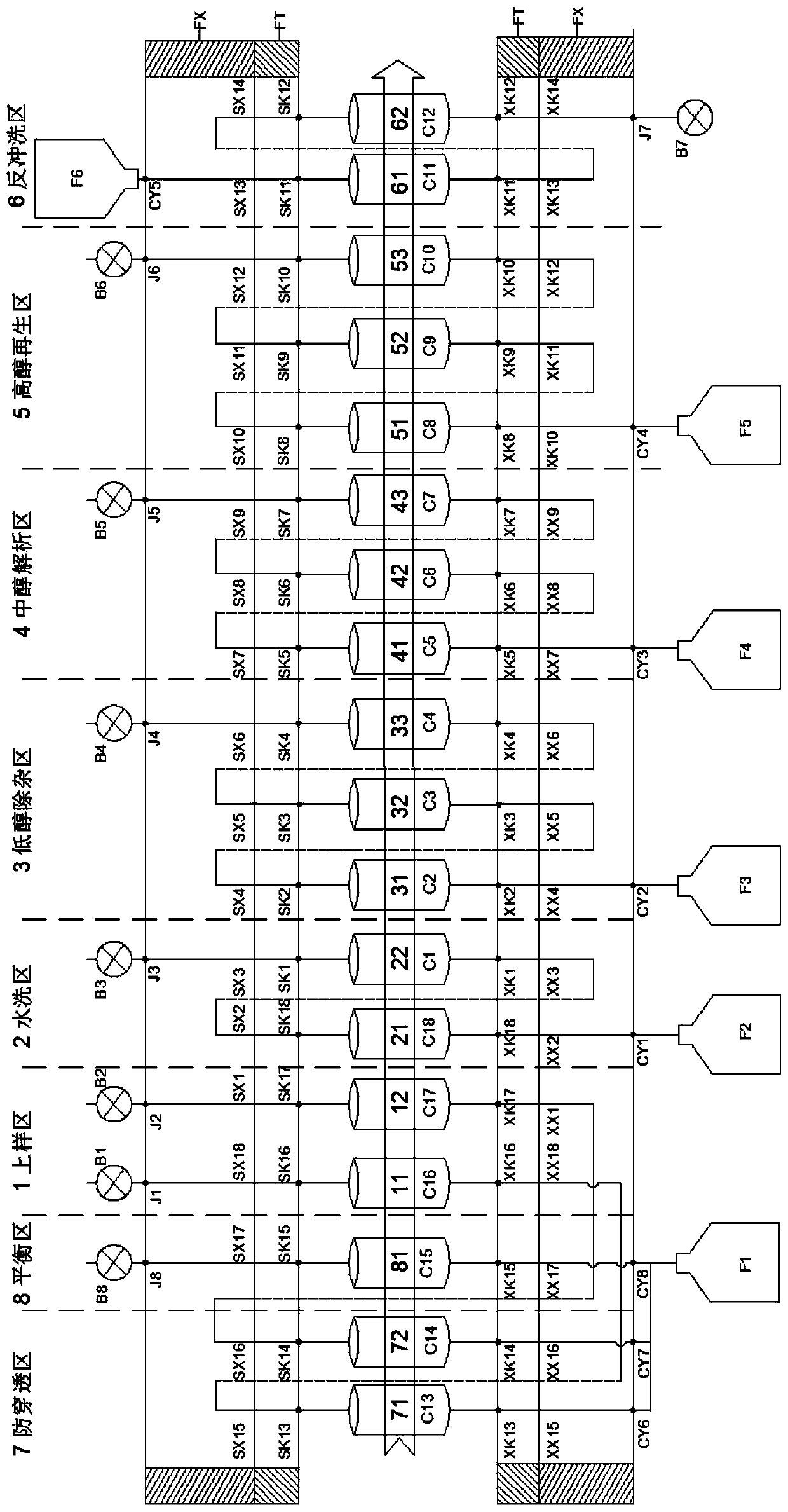

[0098] Such as Figure 1-3 As shown, a continuous chromatographic device provided in this embodiment includes: sample loading area 1, water washing area 2, low-alcohol impurity removal area 3, medium-alcohol analysis area 4, high-alcohol regeneration area 5, There are 8 functional areas: backwash area 6, anti-penetration area 7 and balance area 8 (or application area); each functional area is equipped with a functional station; each functional station is equipped with a chromatographic column C1-C18; all the chromatographic columns are connected with logic control valves, and the logic control valves are used to control the relative movement of all the chromatographic columns relative to the 8 functional areas, so that each chromatographic column is sequentially and circulated through 8 Each of the functional stations under each functional area realizes the transformation of the chromatographic column function and continuous cycle work.

[0099] Wherein the logic control valv...

Embodiment 2

[0129] Such as Figure 7 As shown, the present embodiment discloses the production method of Panax notoginseng saponins adopting the above-mentioned continuous chromatographic device, and its process steps include:

[0130] (1) Pretreatment of Panax notoginseng

[0131] Wash 0.8t of Panax notoginseng medicinal materials (roots, rhizomes, leaves) with purified water, dry and pulverize, add 95% ethanol 3.2t to reflux and extract 4 times according to the ratio of solid to liquid (g:mL) 1:4, and reflux each time 2h, the extract was filtered and concentrated to obtain a certain amount of Sanqi extract, and then the Sanqi extract was adjusted to 3.2t according to the amount of medicinal materials: purified water (g / mL) 1:4, and the water-settled liquid was washed for 8 hours. Filter to obtain the upper column liquid of Panax notoginseng;

[0132] (2) Continuous chromatographic device separation

[0133] The 3.2t Sanqi upper column liquid is separated by continuous chromatographic...

Embodiment 3

[0141] Such as Figure 7 As shown, the present embodiment discloses the production method of Panax notoginseng saponins adopting the above-mentioned continuous chromatographic device, and its process steps include:

[0142] (1) Pretreatment of Panax notoginseng

[0143] Wash 1.0t of Panax notoginseng medicinal materials (roots, rhizomes, leaves) with purified water, dry and pulverize, add 60% ethanol 5t reflux extraction 3 times according to the ratio of solid to liquid (g:mL) 1:5, each time reflux extraction After 1.5h, the extract was filtered and concentrated to obtain Panax notoginseng extract. Panax notoginseng extract according to the amount of medicinal materials: purified water (g / mL) 1:4, dilute to 4t, water-sink for 10 hours, and filter the water-sedimented liquid to obtain the column liquid of Panax notoginseng;

[0144] (2) Continuous chromatographic device separation

[0145] Separate 4.0t of notoginseng liquid on the column with continuous chromatographic equi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com